Print samples from the Konica Minolta AccurioLabel 190

There were plenty of new label presses introduced at Labelexpo. Some we knew about in advance, while others came as a surprise. And customers were quick to sign up. By Neel Madsen.

With the highest number of digital presses ever on show – many of these new launches – there was a lot to take in at Labelexpo Europe 2017. Here are some of the highlights along with news of sales reported.

More roar

Amongst the introductions from Xeikon was the CX500, an extension to the Cheetah series. At a web width of 520mm, the new press is aimed at larger-sized label applications. It prints at 30m/min in a resolution of 1200dpi using dedicated Cheetah dry toner on standard substrates, including direct thermal papers, BOPP, PE and co-extruded films. A DCoat500 finishing machine that was converting the labels in real time matched the press.

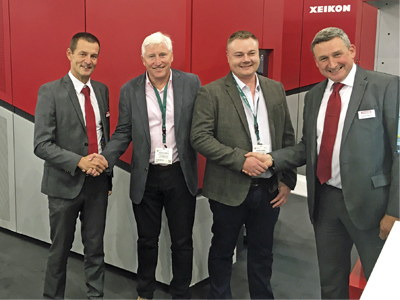

CS Labels took the first Xeikon CX500

CS Labels, in the UK, is the first company to sign up for beta testing of the press. Managing director Simon Smith said, ‘We are familiar with the advantages of a wider web digital press, having two Xeikon 3500 presses. Now that Xeikon has introduced the CX500, we want reap the benefits of this new platform. The enhancements the company brings into this new platform are really impressive, it is a new generation platform indeed.’ He continued, ‘Deciding to beta test the CX500 was a no-brainer for us. It is basically a next, logical expansion of our machine park and if perfectly fits in the long-term business strategy for our company.’

The press manufacturer also added to its new UV inkjet line by announcing a smaller press, the PX2000 220mm wide press, as an entry-level alternative to the 330mm wide PX3000, which was officially launched at the show. Both presses are available in four and five colours, and are powered by the same X-800 DFE that runs all Xeikon presses.

HP extended its relationship with Global Graphics by announcing that the Harlequin RIP has been chosen as the engine inside HP Production Pro, the new digital front end (DFE) designed to drive all of its labels and packaging presses. The Harlequin RIP already provides the RIPping power for the DFE that is used across the company’s commercial press range. The WS6800 will be the first press that comes optionally equipped with the HP Production Pro. This will later be extended to the 8000, 20000 and 30000 presses.

Global packaging group All4Labels was revealed as the first customer to implement the new DFE. ‘All4Labels is a fast-growing company that needs the ability to easily control its production,’ said Michel Koch, digital pre-press manager. ‘HP Production Pro for Indigo Labels & Packaging delivers exactly this capability. When searching for a new DFE, we considered market trends, such as the increase in complex VDP jobs, SKU proliferation and short-term orders to name a few.’

During the show, it was announced that Belgian St-Luc Labels & Packaging had installed the 100th HP 20000 as well as an 8000, while the 50th 30000 press had be gone to Cartoffset in France. Meanwhile, Berkshire Labels and Marsh Labels in the UK both shook hands on a WS6800 press.

Now also with water

Bobst Group company Mouvent came to Labelexpo as a completely new player in the field with big promises and a very large stand. It brought no fewer than three new label presses to market, all printing up to seven colours on paper, self-adhesive and wet-glue labelstock as well as flexible materials at production speeds of up to 100m/min with a native resolution of 1200 x 1200dpi (optical resolution 2000 dpi).

The smallest was the LB701-UV mini label press, configured with inline rotary die-cutting and slitting, while the larger LB702-UV label press was exhibited in a roll-to-roll set up. Both had been seen at the earlier press event in July, unlike the new LB702-WB press, which prints with Mouvent’s own 100% water-based inks to offer cost-efficient, food safe printing.

Martin van Waeyenberge, marketing and sales manager, label machines, said, ‘The fact that people could see [the presses] in action was important, because it makes the potential of this incredible technology come to life. From Labelexpo alone we generated several hundred leads with prospects who want to know more about the machines.’

‘It really was an honour to be in at the same venue with so many leading lights in this industry, and we are delighted that Mouvent generated so much interest,’ commented Piero Pierantozzi, co-founder of the new company. ‘We know that the Mouvent Cluster technology represents a genuine change in printhead integration and it was so rewarding to be able to show its potential to people in the industry. We very much look forward now to deploy this technology throughout the various markets and segments in the weeks and months ahead.’

Low migration version

Screen showed two new iterations of the Truepress Jet L350UV, one of which is using newly developed low migration (low permeability) inks. During the show it was announced that the first LM press would be added to the stable at Springfield Solutions in the UK, making it the company’s fourth Screen purchase.

The Springfield team with their new Screen press

The all-digital printing company had worked closely with the press manufacturer during the development phase advising on various aspects. ‘When Screen announced a new press with low migration inks we were instantly curious,’ said Dennis Ebeltoft, operations director. ‘With the additional accommodations for food packaging combined with such a productive, high quality digital press, it’s a very compelling proposition.’

The press includes a nitrogen purge mechanism for accelerating the curing of UV inks, further preventing ink migration and UV odour. It prints at speeds of up to 60m/min and enables the reproduction of a wider colour gamut by adding support for a special orange ink.

‘Springfield Solutions is forming a habit of making landmark purchases from Screen,’ said Bui Burke, senior vice president sales. ‘Pioneers like them are essential for us to bring the most relevant technology to market. In the case of the L350UV+LM, they advised on additions such as the chill roller, and have been advocates from early on.’

Resolution, speed and colour

Durst reports 145 installations of its Tau series of label presses. At Labelexpo, it launched the Tau 330 RSC, which features Fujifilm’s Dimatix Samba G3L printheads to offer a print speed of up to 78m/min in 1200 x 1200dpi. The new ink set includes green and the press can print on substrates 165-350mm thick. It can be fitted with a chill roller for heat-sensitive substrates, which will enable 20-micron material to be printed. The print module uses inter-colour pinning using UV LED curing, and Durst has developed its own data transmission system, which communicates with the printheads via fibre optic cables.

The Durst Tau 330 RSC was launched at the show

The press was shown as part of a hybrid configuration with Omet’s XFlex X6 flexo modules. As reported in the last issue, the Tau 330 RSC will be beta tested by The Label Makers in Bradford, where it will join the company’s two other Tau 330s. Managing director David Webster said that the increase in printing speed and the high resolution had been the deciding factors in making the commitment. He also praised the addition of the green saying, ‘This means we can cover 98% of Pantone colours.’

Also on show was the entry-level Tau 330 E UV inkjet label press running inline with a new Smag converting line. There are now 40 units of this press installed, including most recently at Italian label specialist Pubbliservice, in Parma, which wanted to enhance its short-run cosmetic, chemical, detergent and food label production.

‘We were looking to increase our printing capabilities and, in particular, meet the market needs for short-run cosmetic, chemical, detergent and food label production,’ said president Stefano Salati. ‘The Tau 330 E UV inkjet press seemed the most suitable solution. The quality and price ratio was great considering the fact that inkjet UV is different from inkjet, which we’re already using. It delivered the right for solution for printing speeds and a lower costs of consumables.’

Ding dong

Nilpeter showed the five-colour Panorama DP3 UV inkjet module fully integrated into a printing line with four flexo units, an FP-4 Flatbed Unit for hot foil and embossing, and semi-rotary die-cutting. The press prints at 600 x 600dpi at 60m/min integrating a Screen inkjet module. A 42-inch touchscreen offers full control of the press, which can also be remotely programmed from an iPad or other tablet.

The pressline has been upgraded to present a more integrated and sleek look, and tempted Italian Nuceria Group, which bought one for its Milan plant. General manager Guido Iannone said, ‘The new Panorama Hybrid product line will follow our strategy to set new industry standards in terms of flexibility, customisation, and supply chain excellence.’ He continued, ‘We have embraced the market trend towards customisation for a long time, and with this investment we will reach the next level.’

The Panorama is also available as a standalone unit as chosen by Swiss label printer Lerchmüller, which made the investment to upgrade old equipment, meet decrease delivery times and increase business in new markets for variable data and personalisation. ‘After a lengthy decision-making process, we have come to the conclusion that the printing quality of the Nilpeter DP-3 Panorama is best suited to the high requirements of our customers,’ said CEO Rolf Dörig. ‘Thanks to the extended colour space in the Vivid colour mode and the high-resolution screening process, the press guarantees an outstanding yet extremely natural colour depth – comparable to HD Flexo quality.’

Tipping point

Director of Domino’s Digital Printing Solution’s business Philip Easton was very enthusiastic in his praise of the show. ‘This is the best show we have ever had,’ he said. ‘We have sold around 10 presses and many of those are to first time customers who came on the stand to buy. This is very unusual, but it is indicative of the fantastic year we have had.’ He continued, ‘We have definitely reached the tipping point and inkjet is now a must-have for mid-range operations. The mindset has evolved to believe that inkjet will play a big part in label printing.’

Domino sold its N610i UV inkjet press to Germark, Hofprint Etiketten and Romero Garcia, amongst others. The press now comes fitted with a new ink set, U90, which has been fully developed in-house and further enables the production of shrink sleeves.

On the stand at Labelexpo, the press could be seen in a hybrid configuration integrated with an AB Graphic finishing line. This set up impressed Emballage Gruppen from Denmark, which had been looking at moving into digital for a while. The company decided then and there to make the investment.

The system features a Digicon 3 with a turret rewinder with automated core size changes. This offers the flexibility to produce high quality, complex labels combining UV flexo and UV inkjet printing, which can also be varnished, laminated, die-cut, inspected and dispatched all in one process. Each output reel can be programmed to the exact number of labels specified by the customer.

Group chairman Otto Christensen said, ‘This investment represents our first step into digital hybrid printing. We have been particularly impressed with the print quality, high productivity and cost-effective production costs. The unique ‘web reverse’ function, which minimises the amount of waste produced to just 2-3 metres even with a job, die-cut or media change, was another contributory factor in our decision.’

More toner

Mark Andy gave the Digital One toner press its European debut. The first in Continental Europe was installed back in May at Primera Polska in Poland, where it has increased capacity by over 800%. The press offers CMYK toner printing and an inline flexo unit for varnish or cold foil as well as a die-cutting station.

According to co-owner Sylwia Dudek, ‘The main benefits of the Digital One are that it can handle a variety of standard substrates without the need for pre-treatment – and without a click charge to pay, the only cost we incur is the inexpensive toner.’ Her husband, Miroslaw Dudek added, ‘The flexo station allows us to apply varnish or add a spot colour, and the laminating unit allows us to use linerless material. There is a UV lamp for curing, and the rotary die station uses easy to change magnetic dies. After that, the matrix is removed, and the finished web rewound – simple, and all in one pass!’

Mark Andy also showed the Digital Series introducing the new QCDC-SR, a semi-rotary adaptation of the company’s QCDC (Quick Change Die Cut) platform. The daily demos showed the hybrid press performing three high-speed job changeovers and three different substrates (white semi-gloss, clear-on-clear PP and a grade 8 estate stock) using three different dies. Additional demo jobs printed included a wine label printed on an estate paper and microbrew labels printed on a semi-gloss stock with VDP elements.

Konica Minolta formally unveiled the AccurioLabel 190 digital toner press, which succeeds the bizhub press C71cf launched two years ago. The company also announced the 100th installation of the label system.

The press prints in a 1200 x 1200dpi resolution in CMYK using newly developed toners, with no pre-coating required. It can run at up to 19m/min on most commonly used self-adhesive substrates, printing in a width of 320mm. The new machine for Europe comes with a web guiding system as a standard and can work as an inline finishing solution together with the GM DC330Mini or as a standalone machine.

Charles Lissenburg, general manager, Professional Print Division, KM Business Solutions Europe, said, ‘Two years ago, we introduced a system that had real unique selling points and thus created real new business opportunities for our growing customer base. We have listened carefully to their feedback, which has really helped shape our ideas and thinking. The new AccurioLabel 190 takes us on to the next stage of our development as a serious player in the industrial markets.’

In Europe, the press has been developed and manufactured in cooperation with Grafisk Maskinfabrik (GM). Elsewhere in the world, the winders will still be provided by Miyakoshi. It is expected to start shipping this coming December.

Keep talking

Dantex had the new PicoJet UV inkjet press running alongside the PicoColour. The press uses Ricoh heads to achieve a resolution of 600dpi, printing in speeds up 75m/min in seven colours and incorporates static control, web cleaning and corona treatment for wide choice substrate in 350mm width. Richard Danon, group chairman, said, ‘It was a natural progression for our company to consider expanding our range from PicoColour. We needed to go wider, faster and finer in resolution, and Ricoh became the partner of choice for us.’

MPS delighted the crowds at the show with live demonstrations of its new ‘talk to me’ connectivity concept on the EF automated multi-substrate flexo press and the hybrid EF Symjet press. CEO Wim van den Bosch said, ‘We believe that ‘talk to me’ is the future. Communication is no longer restricted to just people, but also between machines and among humans and machines. ‘talk to me’ is more than just reading information from the MPS press; it also requires interaction from the operator. With the increased difficulty in finding and retaining skilled operators, ‘talk to me’ automates the process as much as possible, to guarantee high quality print results and productivity.’

The company had great success with the Symjet as two were sold during the show. The first order came from Etikettendrukkerij Noord Nederland (EDNN), a printer based in Hoogeveen, and the first in the Netherlands to purchase the machine. Vincent Belksma, general manager at EDNN, commented, ‘We were looking for a versatile press that could print perfect quality, especially on shorter runs. This hybrid printing solution from MPS and Domino with inline finishing fits our needs perfectly and is a great addition to our machine park.’

The second bottle of champagne popped for DWS Printing from Deer Park, New York, in the US, marking the company’s first MPS press. Established in 1865, DWS is still in family hands, today managed by the fourth generation, brothers Tom and Andy Staib. The brothers visited the Technology and Expertise Centre at the MPS headquarters in Arnhem earlier this year.

Adding inkjet

Inkjet modules could be seen on the Graphium press on the Edale stand, where it was running with the new the EFX Print Bar mounted while FFEI had the Print Bar Uncovered concept on display. Fujifilm launched the Samba 42000 Inkjet Printbar System, which uses its Uvijet ink to offer print quality of up to 1200dpi at speeds of up to 90m/min.

Edale EFX Print Bar on the Graphium press

IIJ introduced the ColourPrint HiQ inkjet module, which uses Konica Minolta’s KM1800iSHC printheads to give an apparent resolution of over 1000dpi at 60m/min (max speed at 600 x 1200dpi is 100m/min). This can be fitted onto any flexo press and is compatible with most UV and water-based inkjet inks. Two of the new modules have already been installed with two more on their way, said managing director John Corrall.

Colordyne added a UV inkjet version to its 3600 Series Retrofit programme of module that can be incorporated onto flexo presses. Gary Falconbridge, president and CEO, said, ‘UV and aqueous inkjet are very distinct technologies, both providing great benefits to customers’ respective applications. Offering these two complementary technologies provides companies the ability to evaluate both side by side and truly understand which is the best fit for their business.’

Read the full November/December issue of Digital Labels & Packaging here. Subscribe to the magazine for free – register your details here.