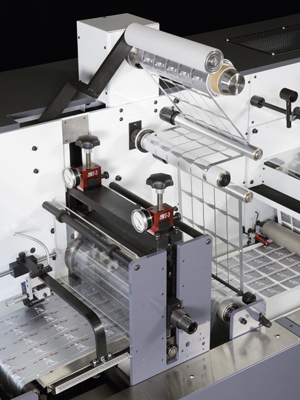

The high-speed Delta ModTech Spectrum system

Many converting lines can be configured to include everything you need to produce finished labels, even printing, so when is a converting line not just a converting line, but an inline print production line? By Neel Madsen.

With the increasing sophistication and added printing capabilities that can be included on converting (or finishing) equipment, the lines between printing presses and finishing equipment have never been more blurred; it’s the ultimate in modularity and flexibility.

So what drives future innovation, we asked the suppliers. Tony Bell, sales director at AB Graphic, said, ‘The next five years is going to be very interesting. Digital printing has matured as a process, but the way in which it is used in the future will undoubtedly change. I think we will see a crossover between the printing and finishing processes.’

CEO of Werosys, Søren Pedersen, agreed, ‘We see the boundaries between print and converting being less defined, and a lot more integrated solutions. We also see the usability of the solutions improve dramatically so label printing and converting becomes something that is primarily set-up from a software interface than a manual process.’

Constant improvement

Delta ModTech has recently doubled the speed of its semi-rotary die-cutting to match full rotary speeds. Jason Newville, the company’s design engineer, explained, ‘Delta ModTech has to keep improving the finishing machine speed especially in the area of semi-rotary. On previous finishing equipment the semi-rotary would run approximately at half the speed of full rotary. If the customer had a long print job, they would turn off semi-rotary and run full rotary at double the finishing speed.’

To meet the demands of shorter job lengths, the company also offers On The Fly laser changeovers. Its integrated laser cutting systems can read a digitally printed barcode that will trigger the laser cutter to change jobs while running.

With the modular equipment the company provides, it is possible to add features and modules to existing machines, as the customer needs them, Mr Newville said. ‘A Delta ModTech machine does not become obsolete when new equipment comes out. For example, the new high-speed semi-rotary can be added to previous version semi-rotary cutting platforms, which would allow you to double your die-cutting speed on your current equipment with the upgrade,’ he explained.

When asked about the secret behind the company’s success, Mr Newville was in no doubt. ‘Service,’ he said. ‘Delta ModTech takes the service aspect very serious. If a company needs support whether it is machine, process or operator-training related, we will do everything needed to get that customer up and running.’

Patented speed

‘Our business success is due to the very strong relationships we have built over the years,’ said ABG sales director Tony Bell. ‘In addition, we also employ a high number of passionate and committed long-term employees both for our UK sites, and offices around the world. Without people, the company wouldn’t be what it is today.’

The demand for higher speeds is behind the latest innovations from the Bridlington-based company. It has so far taken 17 orders for its new FAST Track die, which takes the world record as the fastest semi-rotary die by clocking up 150m/min. Launched in 2016, it has now been awarded a patent. ‘With digital presses running faster and a trend towards inline finishing, there is a definite demand for higher speed semi-rotary die-cutting,’ said Mr Bell.

He continued, ‘Once the FAST Track die was born, we quickly focused on improving the set-up time of turret rewinding. Enter the Vectra SGTR Auto set glueless turret, a revolutionary turret rewinder; it automatically sets up in seconds, which allows it to be used for even the shortest of runs.’

At the upcoming Labelexpo, ABG is launching a new flatbed screen-printing unit for the Digicon Series 3. Mr Bell said, ‘Flat screen-printing is traditionally the slowest module on any finishing machine. Our designers have been working on improving this, and our new unit has a significantly increased running speed.’

The new module has a full rotary web motion, whilst still using a flatbed screen. The size has been reduced by over 20%, while the repeat area has increased to 410mm in the web direction making it compatible with the Big Foot 50 hot foil stamping unit. There is also a chill roller option for delicate substrates.

Ready for 4.0

GM has developed a new finishing line, which will also be introduced at Labelexpo in September. The DC-350 is faster, bigger and more automated than the company’s previous lines and features semi-rotating varnishing (partial varnish), jumbo roll unwind and rewind, job database and internet connection. CEO Uffe Nielsen said it is ‘truly an Industry 4.0-ready machine.’

He stated, ‘GM is driven by innovation and smart market solutions. We are the go-to company for customised finishing lines in the high-end market. The company has a strong track record for quick turnaround on client request for label applications.’

The company continues to grow. It doubled its production space two years ago, but this is now full. Mr Nielsen said, ‘We are constantly looking for ways to increase our production and limit lead times.’ Customers are asking for more automation and lines with a smaller foot print. ‘Space and the high costs of man power is becoming a major problem in many print shops.’

One of the company’s most compact lines is the DC330 Nano, which is described as a cost-effective unit offering unwind, self-adhesive lamination, semi-rotary die-cutting and length slitting on a 1.3 x 1.3m platform. Mr Nielsen said, ‘This ultra compact unit is ideal for a small digital press or as a backup to an existing finishing line. It can run either offline or inline.’

In another galaxy

Converting equipment for digitally printed labels represents 50% of turnover, equivalent to €20 million, for French manufacturer Smag Graphique (a division of SRAMAG SAS).

Labels being finished on a Digital Galaxie from Smag

Managing director Stéphane Rateau said, ‘Smag is a medium-sized company with 70 employees and we manufacture everything in house. The key success is really the very close relationship we have with our customers, and the customisation we can offer them.’ He continued, ‘The main demands we are getting are for minimising set-up time and less waste, and also increasing the connection with the workflow. We have permanent developments in order to reduce downtime, increase speeds, link the machine to the pre-press as the digital printing engine.’

The company offers three products lines and installed 61 systems in 2016. The 350mm wide Digital Galaxie is based on the Classic Galaxie of which there are more than 300 installed worldwide. It is a modular platform with options including flexo station, high-speed flatbed screen, high-speed flatbed foil and embossing, laser cutting and semi-rotary die-cutting.

The E-cut is an entry-level machine, which comes fitted with a flexo station for cold foil or varnishing, lamination and semi-rotary die-cutting. A new generation of this machine will be shown at Labelexpo, in 350 and 530mm web widths.

The new EFS machine developed specifically for converting labels printed on the Durst Tau UV inkjet presses will also be on show in September. The cooperation with Durst was announced earlier this year and initially covers Europe and Latin America.

Acceleration

Customisation is a driver behind Rotocontrol’s success, with finishing customisation capabilities as standalone or integrated inline with presses and other equipment. For digital, it has the DT series, which has seen a growth in sales in step with digital press installations.

Marco Aengenvoort, managing director, commented, ‘The interest and sales of our DT series finishing solution for digitally created labels have accelerated in the last few years, and significantly contributed to our overall 30% increase in sales in 2016. The capability of inline finishing with digital presses is a significant factor, in addition to multiple options allowing us to highly customise the machine.’

The modular machine runs at speeds up to 67m/min in semi-rotary mode. Optional modules include a semi-rotary printing station, a semi-rotary die-cutting unit and unwind module, and a slitting unit with automatic non-stop turret dual rewind.

One recent installation is at Hagmaier Etiketten & Druck, in Germany, which was looking for flexibility in finishing to complement its digital printing expertise. Valeri Merkel, Hagmaier’s production manager, said, ‘Rotocontrol was very open to implement our many special requirements and optimally build the machine according to our expectations.’

South American installation

Newfoil Machines has been producing off-line finishing machines for 35 years. ‘The largest marketplace at the present time is for equipment to finish digitally printed webs,’ said managing director and owner Derrick Evans. He continued, ‘The growing number of installations of these presses is forcing users to look for better, more efficient methods of adding value and reducing overall label costs. In capital, maintenance, operating and set-up costs, the Newfoil finishing system has many advantages over the inline rotary solution; add to this the easier control of quality on a small compact machine.’

Victor Espinoza, owner of Edobol, in Bolivia, with his Newfoil 3534

Recently appointed agent for Bolivia and Chile, Ferrostaal SAC has now sold its first machine to Edobol Ltda of La Paz. Victor Espinoza, president and owner of Edobol, chose the machine to complement his HP Indigo press, and it will be finishing high-value wine labels, adding hot stamp foiling and embossing.

The 3534 Servo press combined with a flexo varnishing unit, UV/IR drying, corona discharge and heavy-duty unwind and special rewind is also the first Newfoil machine to enter the Bolivian label industry. It features a servo-driven flexo varnishing unit that can be used for flood coating substrates, spot varnishing and colours, while UV and IR drying give the flexibility of using a wide range of inks and lacquers.

Mr Evans explained that offline finishing is a very effective way of processing webs from digital inkjet and laser machines. The low-cost flatbed tooling used on the Newfoil equipment enables short run, high-value labels to be produced effectively. Set-up times are low, particularly if the “Quickset” tooling is employed for embossing.

Foiling and embossing can be combined through the use of a “combination” die where the two processes take place simultaneously. This reduces set-up times and costs as well as increasing the potential speed of the process. The Newfoil range of machines runs at speeds up to 75m/min or 18,000 cycles per hour.

The combination of flatbed screen-printing, hot foil stamping and embossing is increasingly popular with Newfoil customers who service the wines and spirits label sector. High quality labels featuring “silk foil” and thermally expanding inks to give a domed effect are proving to add value to labels and have greater customer appeal.

In combination

Modularity, or “intelligent converting” is the main concept from Werosys. ‘Depending on how you combine the Werosys Compact modules, your label production systems can be anything from a true digital finishing solution with UV varnish and cold foil, to a fully configured hybrid printing solution with a combination of flexo and digital printing,’ explained CEO Søren Pedersen.

He continued, ‘We provide our customers with solutions that allow them to be more efficient, reduce waste and do quicker changeovers – essentially be able to make money on even the smallest batch sizes of labels. We achieve this by supplying solutions that are truly digital, and that are set up automatically by extracting data from the customer’s existing IT infrastructure.’

The company’s latest innovations include a fully automatic flexo station, a digital print engine and a laser cutting module, which means that it can now configure a full label production system, including printing and converting in a single-pass workflow. The digital finishing line reads all necessary information from the PDF file, or similar, and automatically sets all stations, including the digital inkjet printer, laser cutter and automatic slitting system.

Future platform

Italian manufacturer Prati reports that it is manufacturing the Digifast finishing line in batches of 10 machines at a time. It will be showing two models of the machine at Labelexpo: a compact version and a top-end model to demonstrate high-speed, accurate processing of added value labels as well as wine bottle labels.

Chiara Prati, sales and marketing manager, said, ‘You need to listen to the needs of label printers and understand them, analyse the market, improve what has already been invented and re-invent it. Our recently launched open-platform concept – Futura technology – safeguards the customer’s investment and is always ready to satisfy evolving market requirements.’

Futura is a scalable architecture concept that makes a machine ready for present and future market requirements, HRWD (Human Resource and Workforce Development Education), SFTW and Ready for Digital, to fully comply the demands of Industry 4.0, she explained.

Looking to future developments, Mrs Prati continued, ‘Converting equipment will be a fundamental part of the printing process, even more so than printing itself. Equipment should be able to deliver high-quality finished and embellished labels and unsupported materials in the fastest possible way, with as little waste as possible.’ Full automation should

be achieved through connection with the MIS with self-configuration

of the machine according to the production process and link of these processes.

Read the full August issue of Digital Labels & Packaging here. Subscribe to the magazine for free – register your details here.