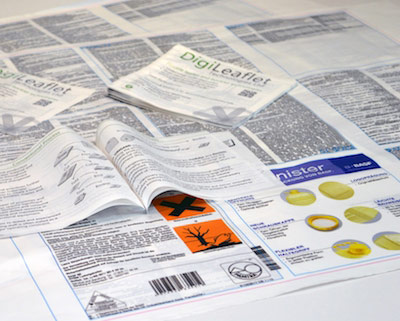

Digitally printed booklet labels from iDi PAC

As demand for product personalisation, growing content and the macro trend toward ever smaller production batches grows, a flexible booklet manufacturing solution that serves the needs of the short run is increasingly relevant, for convertors and as an in-house process for many.

Creating optimised, targeted, product information is key to motivating use and generating understanding from users across agrochemical, pharma and other technical product markets. Within the pharmaceutical industry, adherence to prescribed treatments is a key area of opportunity that works to provide a focus on delivering better patient outcomes; achieved by delivering best practice presentation of therapeutic content.

Furthermore, the presentation of patient information in the pharmaceutical industry regulated in the UK by the Medicines and Healthcare Regulatory Agency (MHRA) is essential in ensuring that the patient has access to high-quality information – key if medications are to be used as intended, without supervision.

Using a familiar format, logical flow of information all within full-colour designs, readable font sizes and appropriate graphics ensures the best outcomes are consistently delivered for patients in Pharma and farmers in AgChem. DigiLeaflet (DLT) was born out of the need to cost effectively meet this challenge; the demand for short runs, customised content with rapid turnarounds.

Existing production methods, whilst effective, struggle to meet the demands of the agile supply chain model; quantity and flexibility. To remain competitive and meet growing yet diverse market needs, businesses recognise the need to minimise stock write-offs derived from industries typically large and inflexible Minimum Order Quantity conditions.

The need for highly skilled staff within a capital equipment heavy manufacturing process to produce booklets can now be achieved in a single streamlined process. One that also works to open additional business opportunities.

Printers and convertors are now able to handle small volume demand, cost effectively, within existing processes. The simplified DigiLeaflet process also opens the door for brand-owners who seek greater autonomy and the opportunity to bring booklet making in-house.

Innovative thin-film handling and folding techniques are used within the DigiLeaflet ‘Origami’ machines to produce robust, lightweight, colour communication formats that effectively deliver instructional requirements across a broad range of markets.

Unlike conventional processes, with DLT one operator is able to run a single machine that can convert a reel of thin film, typically 30/35µm material, directly into a booklet format. By adding digital print in-line, utilising Industrial Inkjet DOD technology, full-colour booklets can be created in a single pass. The final conversion stage maximises print area availability, using ultrasonic weld technologies to create a flexible spine of exceptionally narrow width. The digital technology; print and machine allowing artwork and formats to be rapidly changed and if required pre-printed stock utilised.

The thin film utilised provides further performance and delivery benefits; the matt surface enhances legibility and readability and is accepted for use by the MHRA. The 30/35µm material is used to create multi-page booklets that, due to their robustness can be applied directly to packaging, included as an insert or incorporated into booklet labels adding further flexibility and reducing manufacturing costs of those items.

Unlike conventional booklet production processes which generate waste, require skilled operators and additional resources for set-up and trim etc, DigiLeaflet has evolved to deliver upwards of 60 booklets per minute from unprinted reels or pre-printed stock into finished items – within a simple, single machine and process.

With their flexibility, rapid format changes and digital capability it is clear that the DigiLeaflet ‘Origami’ machines are set to have a significant impact on the economics’ and flexibility within the booklet manufacturing sector.

This article is an advertorial; the featured company created the wording and paid for its placement. It has been thoroughly checked by Whitmar Publications to ensure that the information is accurate and meets our standards.