Fusion technology from Xeikon is changing label and packaging printing from the ground up. The market has already responded positively to Xeikon’s announcement that in future it will be possible to carry out digital printing and digital finishing on one platform and in one operation. Filip Weymans, director of segment marketing and business development for labels and packaging at Xeikon, explains.

As the first professional digital printing presses came onto the market at the start of the 1990s, the mood in the printing sector was optimistically pioneering at the new options opening up for print products. Many print manufacturers jumped onto the bandwagon and provided the sector with a variety of digital printing solutions. Today, digital printing has a permanent position in all areas of printing, including commercial printing, large format printing, document printing, and especially in label and packaging printing. Digital printing is regarded as a serious alternative to conventional methodologies for the cost-effective production of personalised and static small to medium-sized runs. The latest developments from the manufacturers in output speeds will also make it profitable for larger runs in the future. Look at the launch of the Xeikon CX3 in the past year, for example, based on Cheetah technology, offering speeds of up to 30 metres per minute.

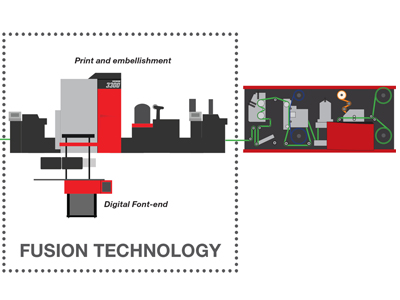

What I also want to point out is this: digital printing has continued to develop and has now become a mature technology when it comes to full-colour ink transfer onto paper, film and many other materials. Printing is enhanced by the use of a fifth colour station for colour space expansion, custom colours, the Creative Colors Metallic effects from Xeikon, as well as technical colours such as opaque white. Braille letters or security colours are also possible and are well utilised. What digital printing is not yet quite so good at, however, are extremely high quality print finishes such as those that could previously only be created using analogue technology. And this is where the new Fusion technology from Xeikon comes in: this new concept is intended to help fulfil the promise of the fully automated, unsupervised production of high-end labels and packaging from customer order right through to shipment. This means that the printing and finishing of labels and packaging can be carried out in full-colour as a fully digital production process in just one operation and in-line on just one platform.

Modular principle: digital finishing modules

The Fusion concept covers a range of finishing modules that will be made available in stages. These modules are not only installed simply in-line with the printing press, but are components of a new modular system built from the ground up. The digital front end (DFE) plays an important role here in that it makes possible prepress, data processing, colour management and operation of the printing press, as well as the control and operation of all finishing modules without any manual intervention. The digitally controlled modules can be integrated into the production line before or after digital printing. The important difference from analogue finishing techniques is that Fusion modules are digitally controlled and carry out digital finishing of the material accordingly. To achieve this, Xeikon works closely with print head manufacturers. The objective is to use ink-based digital techniques to create the desired finishing effects. The potential digital finishing types include hot/cold foil embossing, high-cover opaque white in screen print quality, relief and structured varnish, partial spot varnish (both transparent and colour) as well as a Braille printing module. The first modules for high opacity cover white and spot varnish applications are slated for release as early as 2017.

Making the most of finishing techniques

In label printing in particular, the desire for high quality finishes is strong: you only have to look at high-end wine bottle labels, where these days embossed elements and gloss effects are virtually de rigueur, to see all the potential ways to appeal to customers. This is also confirmed by a Xeikon survey of all its customers around the world. It revealed that label processors for the cosmetics, wine and spirits sectors in particular have the greatest interest in the new Fusion technology. Next in line are pharmaceuticals and food and beverages in general. When it came to preferred finishing techniques, these ranged from high cover white in screen printing in first place, followed by hot and cold film embossing, structured varnishes and Braille printing (primarily requested by those in the pharmaceutical industry).

Fusion technology from Xeikon offers processors genuine flexibility, allowing them to produce virtually any labels and packaging on request, no matter how complex. It will also simplify the re-printing of previous jobs as all the necessary parameters are stored in a single file. Above all, though, processors no longer need to invest in offline solutions, and as a result are no longer subjected to the time disadvantages and potential errors that are unfortunately often involved with downstream offline work steps and manual intervention.

Following the exceptionally successful initial announcement of its future vision at Labelexpo last year, Xeikon also presented the Fusion concept at drupa 2016 in specific technology demos to an even wider printing and media audience and demonstrated what will be possible in the future. Even at Labelexpo with a less complete demonstration, the reception was overwhelming. There was considerable interest from experts in the field as to how the modular concept could help them select the solution best suited to their production requirements, coupled with the option of handling more items, ever more complex jobs, even smaller runs and shorter delivery times, and managing the ever-present time pressure and challenges in daily operations better and faster.

Jesús Glaría, CEO of Zaforsa, a Spanish Xeikon customer, has been won over by the concept of digital print finishing: ‘Fusion technology will allow us to take on an entirely new market and to carry out complex finishing on premium labels in an amazingly minimal amount of time. If we want to produce high quality wine labels today, we still need to combine digital printing with conventional finishing techniques. This means we lose the time that was gained from the flexibility and speed of digital printing. We see Fusion technology as precisely the right solution to overcome this production downside.’

What exactly is ‘Fusion’?

The aim of Fusion technology is to provide a seamlessly functioning, continuous total production system for labels and packaging with short delivery times at top quality levels. In many cases, this will include various details and comprehensive finishing effects. Taken together, all these measures increase the interest factor for a product and the shelf appeal of a brand. In short, it’s all about faster production of premium labels and packaging; a sector that is increasingly in demand. This hypothesis was also confirmed in the survey of Xeikon customers.

With Fusion technology, a print job designed for multiple processing channels is ripped stored in a hot folder. The various channels for defining each individual aspect of the production process are then controlled without manual intervention using the relevant modules, including the press.

Conventional finishing modules require specific tools such as embossing stamps, flexo printing plates for cold film embossing, varnish stations for spot and structured varnish application, and UV screen printing units for opaque white/Braille lettering. The advantage of the digital solution is that it does not require any tools, saving costs as a result. Secondly, each individual design element can be variably designed or personalised. This is a factor not to be underestimated when it comes to creating new high-potential opportunities. For example, pharmaceutical packages can be sequentially numbered in Braille. Depending on customer requirements, the digital finishing modules can be positioned before and/or after the digital five-colour printing press from Xeikon. The resultant configuration produces digitally printed and finished labels and packaging in a single-pass operation.

At the heart of this concept is the five-colour digital press from Xeikon that uses the dry toner electrophotography process. It provides the optimum solution for the premium labels and packaging market at present as it easily conforms to the standards of offset and flexo printing in terms of precise positioning and extremely uniform quality of the print dots. The corresponding dry toners from Xeikon have been designed specifically for these applications to meet the market’s requirements for print quality, colour accuracy, light resistance and food safety as well as a broad colour gamut and brand integrity. The digital front end (DFE) X-800 developed by Xeikon facilitates an automatic digital print workflow and simultaneously permits integration into existing workflows as well as into third-party applications commonly available on the market such as design packages, web-to-print applications and MIS systems.

Conclusion: A new dimension in digital printing

Fusion technology responds to a clear and, in our opinion, significant need in the label and packaging market. Initially Xeikon will be concentrating on self-adhesive labels where, as mentioned above, a considerable increase in demand for small runs of premium labels can be expected. This applies in particular to luxury goods such as cosmetics, wine and spirits, as well as confectionery. With pharmaceuticals and similar products as well, print finishing effects for anti-fraud protection can be used. Establishing and protecting a striking brand image is just one side of the coin. Anchoring this brand image into the minds of customers in an environment under significant competitive pressure and increasingly overloaded with information, and achieving high sale figures, is the other side of the coin. The combination of digital printing and digital finishing has what it takes to make a significant contribution to achieving both aims.

With the Fusion concept, Xeikon is taking digital printing to its next logical iteration. Instead of previously ‘only’ printing digitally and carrying out the subsequent print finishing processes using analogue techniques, the digital print pioneer is now developing solutions where even print finishes can be created digitally.

This article is an advertorial; the featured company created the wording and paid for its placement. It has been thoroughly checked by Whitmar Publications to ensure that the information is accurate and meets our standards.