An array of Fujifilm Dimatix Samba inkjet heads in Heidelberg’s Primefire 106 carton press

Inkjet label and packaging presses contain expensive printheads, maybe hundreds in big presses. Heads are critical components, making long life and consistent performance vital. The variety of mechanisms and suppliers means competition to push the sector forward. By Sean Smyth.

There are two categories of inkjet printhead. Continuous means ink is always passing through the nozzle, it breaks into drops with a mechanism to separate non-printing drops, leaving others to build up the image. The alternative is drop on demand (DOD) that generates a printing drop as needed, using either a piezo or thermal actuator. There are benefits and drawbacks to each type and equipment designers select heads they believe will provide the right mix of performance, quality and cost.

All heads comprise nozzles, ink delivery, temperature control and electrical connectors to the driver. Head performance is determined by the ink and the front end, the head has to ensure every signal to print results in an identical drop of ink being ejected. Slight variations in the dimensions of ink channel or nozzle may lead to changes in drop formation, or give rise to satellites. Some of these effects can be compensated for with a waveform specific to the individual head that can adjust the voltage to each nozzle, while calibrations on different substrates are required.

The ideal head performs consistently over many years, in production environments where machines may be operated intermittently, on shifts printing onto many substrates. In fixed-head configurations some nozzles may not be required on some small format jobs. Heads tend to run into problems when nozzles are not regularly used. Water and solvent inks may dry in the head, blocking nozzles, which can result in noticeable lines in the print, but suppliers use several strategies to overcome such artefacts.

Nozzles and drops

HP designs multiple rows of nozzles and incorporates redundancy into its heads. If one nozzle is blocked, the head uses another to deliver the drop. Other suppliers will increase the size of dots adjacent to the blockage. When there is a stop the head can be cleaned, unblocking the clogged nozzle. There has to be a detection system for lines and missing nozzles, and many presses use cameras to detect defects and rectify them.

In 2015 HP announced the launch of its HDNA (high definition nozzle architecture) heads, offering a native 2400 dpi resolution with dual-size ink drops that improves print quality at 122 m/min. In flat tints it provides very good smoothness, which will be useful to reproduce brand spot colours accurately. The new heads contain 21,120 nozzles in the same body as earlier heads, allowing existing inkjet machines to be upgraded in the field.

Kodak’s Stream continuous technology provides a significant benefit to water-based inks. Because ink continuously passes through nozzles, there is no problem of drying in operation, so the ink does not contain as much surfactant and humectant as DOD inks, which are not useful when ink hits the print surface. Stream heads form 11 pl drops and tiny nozzle heaters create smaller 4.75 pl drops. Laminar airflow across the head blows the smaller drops into a recirculator, leaving only the larger print drops. Ultrastream develops the process using an electrostatic mechanism that uses smaller drops to print. Each nozzle can deliver 400,000 drops per second at of 600 dpi across the web and 1800 dpi in machine direction, giving high quality up to 300 m/min.

Epson, Fujifilm, HP, Kodak and Ricoh manufacture the heads in their equipment, while others will select heads from the competing vendors, often using different types of head across their equipment. HP does not sell its thermal heads to third parties although it does rebadge third-party piezo heads in some machines, currently the latest Epson heads are only used in its equipment.

Heads on the market

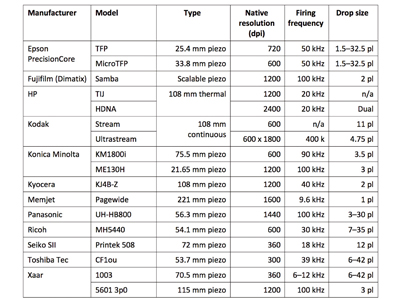

The table lists the currently available and announced heads. Most models are a family of products, tuned with different drop sizes and suitability for various ink types. Over time the head makers improve the design and manufacturing methods of their products and introduce new models.

Figure 1 Available printheads

Printhead design balances image quality with speed and cost. In packaging there may be conflicting requirements. Text must be clear and sharp, barcodes must be legible, image smoothness and detail is important, while tints and solid areas must be smooth. White should be smooth with maximum opacity, process sets may be augmented with orange, violet and green to maximise colour gamut. Most heads offer greyscale capabilities, where different sized drops are printed, with component droplets coalescing at the generation stage or in flight. The alternative is binary printing, where fixed size drops are either printed, or not. The benefit of greyscale printing is improved quality at the same native resolution, the drawback is higher data load to drive the head.

Next generation

The recirculating Xaar 1003 greyscale heads are widely used in labels and the fast developing direct to pack sector where the high reliability in hostile environments is a major benefit. The ink is constantly moving, preventing even heavily pigmented white settling out. Heads can be aligned either horizontally or in vertical ‘skyscraper’ modes, making them compatible with handling systems on bottling and filling production lines.

MEMS technology

Manufacturing high volumes of consistent heads is not easy using mechanical precision engineering cutting, gluing and assembly. The latest heads from Xaar and Konica Minolta will be manufactured using MEMS (micro engineered mechanical system) techniques. These methods were developed by computer chip manufacturers to fabricate complex powerful silicon wafer processors. The methods have spread to other sectors, including inkjet heads from Epson, Fujifilm Dimatix, HP, Kodak, Memjet and Ricoh.

MEMS takes a silicon wafer and etches it selectively creating a structure, then deposits materials to produce components. In inkjet well defined small details are engineered consistently, including the jetting orifice and ink chamber with very thin, regular walls. Suppliers can increase nozzle density while improving durability using tough, stable silicon, to boost head life with many ink types. For piezo heads techniques of depositing thin layers of piezo material in position onto the chamber have improved, leading to the ‘Thin film’ heads with walls under 10 microns thick in use.

The methods allow improved head design, then manufacturing to be more consistent and predictable. Investment in a MEMS inkjet head manufacturing facility is significant, certainly in the tens of millions of dollars, but the reward is high yield, consistent high volume production. It leads to economies of scale, with manufacturing cost falling as more capacity comes on line. As piezo heads can cost up to several thousand pounds, so this will be a significant driver to further inkjet adoption.

New generation MEMS Xaar 5601 3p0 printhead

Xaar announced its next generation MEMS heads at drupa, the 5601 series that handle water-based inks. Each head has over 5600 nozzles featuring a native resolution of 1200 dpi at eight grey levels. The Xaar 5601 3p0 is the first launch at the end of 2016. It has four sets of nozzles arranged in a Z-configuration to deliver 115 mm print width and Xaar is highlighting carton printing as a key application. It recirculates ink past the back of the nozzle at all times even during drop ejection, a feature that has made the 1003 series of heads so reliable.

Scalable arrays

Head suppliers are working to improve quality, speed and reliability. For some packaging applications large drop sizes to lay down heavy coverage of white or coatings are needed, while image and text quality require small drop, high resolution capability.

Manufacturers are making heads more compact, and easy to produce scalable arrays that can be integrated into press and converting lines.

Analogue press suppliers are learning how to integrate single pass arrays into their machines to deliver high performance, high quality print systems. Initial launch speed of many of these systems is lower than the manufacturers are promising to deliver, showing that they are steadily working to deliver the full capability of the printheads.

It is difficult switching to a new head even if it is identical in size and shape. The fast developing sector means this will be increasingly necessary to reassure early adopters, however. The growth in the supply base, bringing new engineering approaches and development budgets will see new head technology coming to the market to boost the adoption of inkjet in packaging, with upgradability a key feature.