There will be 19 halls of printing delight at drupa 2016

Promising visitors that they can touch the future, the print exhibition Colossus that is drupa will take place in Düsseldorf in Germany on 31 May to 10 June. Neel Madsen looks at the highlights.

Times and technology has changed somewhat since drupa in 2012. Most notably the biggest exhibitor is this time a digital press manufacturer, namely HP, which together with its partners, takes over hall 17 in its entirety.

Packaging production is one of the highlight themes, which will be in focus at so-called Touchpoints. Packaging has a dedicated space in hall 12, on stand B53, where four futuristic working laboratories will display case studies, the latest packaging design and future concepts.

The mega trend at drupa 2016 will be Print 4.0 said Claus Bolza-Schünemann, chairman of the drupa committee and chairman of the board at Koenig & Bauer AG quite early on. ‘Print 4.0 enables individualisation and personalisation in digital printing. In the face of high quality packaging and the rapidly diversifying range of solutions in industrial and functional printing this digital networking of machines and systems offers the solution and guarantee for efficiency and competitiveness.’

In the cube

In support of the themes, the drupa cube will feature a conference programme of presentations from industry leaders, innovators and analysts promising ‘a glimpse into the future of print.’ This includes a talk on the prospects for printing in the packaging market by Dominic Cakebread, head of packaging consultancy at SmithersPira, while Sean Smyth (also SmithersPira) will be moderating what has been called a ‘gladiator session’ on digital vs flexo in packaging and point of sale markets. There will also be talks on printed electronics, smart packaging, augmented reality, as well as guidance given on how to get into new markets and growing your business.

Keynote speakers are Frans Johansson, CEO and founder of The Medici Group, Silas Amos, a creative strategist and expert who works with many global brands, and Shane Wall, global CTO of HP Enterprise.

In the pavilion

Picon is setting up shop in four pavilions where 21 of its members companies will be exhibiting. Over 600 square metres, across four halls, the Picon Pavilions will showcase Best of British companies offering a variety of specialist equipment and services spanning pre-press, printing, finishing and ancillaries.

The companies include Alphasonics, Applied Laser Engineering (ALE), BCS, Compact Foilers, CyanX, Dies Direct, Edale, FFEI, Focus Label Machinery, Heights (UK), Imprint Business Systems, Infigo Software, Magnesium Elektron, ManMat, Profoil, RK Print Coat Instruments, Rollem, Security Foiling, SF Services, Troika Systems and Victory Lighting.

‘The fact that we have 21 companies participating in the Picon Pavilions at drupa, including several for the first time, indicates the optimism of UK manufacturers and eagerness to build their export markets,’ commented chairman Robert Flather.

On show: A-Z

AB Graphic International will be present with partner HP (Hall 17) to show its finishing and converting capabilities, notably the new FAST Track die-cutting module developed for the Digicon 3, and billed as the world’s fastest semi-rotary die-cutting system. ‘We are very proud of this world first,’ said sales director Tony Bell. ‘The FAST Track die can run at speeds of up 150 m/min in semi-rotary mode, with a repeat range of 250-508 mm. With digital presses running faster, and a trend towards inline finishing, there is a definite demand for higher speed die-cutting.’

Afinia (Hall 6/D08) will show its full range of digital label printers, including the new C900 desktop corrugated and card printer, and the DLP-2000 digital label press along with the L801 desktop colour label printer. For the production of a wide range of labels in different sizes and shapes, the DLF-1000 Digital Label Finisher will be demonstrated. This works with a plot cutting system and will cut any shape on demand without the delays or die/tooling costs. The R635 is a laser printer that produces full colour, highly quality labels suitable for GHS labelling and other applications where durability is required. This machine has recently been upgraded to include a white and/or fluorescent colour option.

Bobst (Hall 10/A60-1) will be highlighting its digital corrugated press and is also promising to lift the veil of a digital press for folding carton, paper and film, which is under development and due to be launched in 2017. Stephan März, worldwide head of the services business unit, said, ‘We aim to be a guiding partner, helping our customers succeed whether it is by providing services that help them make the most of their existing equipment, by supplying highly productive new solutions for conventional processes, or by offering disruptive new technologies such as digital print.’

Cartes (Hall 10/C41) will have the GT 360 and Gemini series of finishing and converting lines on its stand. The Italian manufacturer has over 4000 machines installed worldwide.

Cerm will be present on a number of partner stands, including Heidelberg in Hall 1 and HP in Hall 17 to demonstrate that its technology is more than MIS and drives the complete workflow automation for narrow web printing. Other partners include Chili Publish, Xeikon and Esko. New versions of the Cerm digital shop front Web4Labels will be introduced. Based upon the feedback from its W4L user group, the company decided to re-engineer the existing tool from scratch. This includes responsive web design for mobile devices and flexible information grids that will give the printer the possibility to customise the information for each individual customer.

Chili Publish (Hall 7a/F40) will launch two advances for the company: Chili Publisher 5.0 and a new PDF rendering solution called Chili Rendro. The company will also share details on expanded partnerships and case stories of customers’ success.

Colordyne (Hall 5/C24) will be showing its memjet-driven 3600 series digital press including options to retrofit. The stand will serve as a workshop demonstrating how Colordyne can streamline business workflow. Its complete digital printing solutions portfolio will be on display with the Production Class 3600 Series Sprint press running. New enhancements to the 3600 Series means that the unit now prints at 152 m/min at a resolution 1600 x 725 dpi, a increase in speed from the enhanced efficiency mode 102 m/min at 1600 x 1135 dpi announced at Labelexpo last year.

Retrofit module from Colordyne

Condair (Hall 16/D43) is creating Europe’s largest temporary humidification system for the show to maintain the optimum humidity in both the Heidelberg and the HP halls. A total of 50 Draabe high pressure humidifiers are being suspended from the halls’ ceilings to maintain an optimum 55% relative humidity (%RH). A low humidity can lead to static problems and cause the paper moisture content to drop, with a resulting change to its physical size. This can happen surprisingly quickly, with paper losing up to 20% of its moisture content in just 90 seconds when exposed to a humidity of less than 40%RH. Four Draabe PerPur water treatment and high pressure pump units will be treating and supplying the water to the humidification systems, as well as supplying pure water to the Heidelberg printing machines.

Creative Edge (Hall 7/C16) will be releasing version 4 of its iC3D packaging design software, which now incorporates new features for 3D photorealism. CEO Nick Gilmore said, ‘With each software version, we have fine-tuned practical aspects, such as the range of applications, product types and shapes. Now with unprecedented photorealism too, the missing piece is in place to leverage the full capabilities of this technology – and drupa is the ideal place.

Datalase(Hall 6/A19) is extending its portfolio of laser inline digital printing technology and bringing to market the ability to deliver variable data on pack in a new selection of monochrome colours. It will demonstrate the new Variprint development, which like its existing version can be applied on a variety of primary and secondary packaging materials for late-stage customisation.

Dilli (Hall 10/A21) will show the Neo Mercury digital inkjet press, which is available in two versions depending on the printing width; the 324 mm NM-350W and the 216 mm NM-210W. It prints in CMYK+White through 15 Kyocera industrial inkjet printheads at a resolution of 1200 x 600, with a smallest droplet size of 3 picoliters.

Domino (Hall 5/A23) has worked with new partner IBIS Bindery Systems to present a new booklet production line. The Domino K630i monochrome digital press will print inline with an IBIS digital saddle-stitcher at web speeds of up to 150 m/min to produce up to 7000 book blocks or booklets per hour. Kern AG will be providing the unwinder, buffer and the rotary cutter for this line. Also shown for the first time is a B2 digital printing sheetfed solution encompassing the 782 mm print width K600i monochrome printer. This system will operate at up to 120 m/min printing on sheets from 60 to 250 gsm.

Finally, the N610i seven colour inkjet label press will be running at up to 75 m/min using high impact UV-curable inks. Philip Easton, director of the digital printing solutions division, said, ‘In addition to our screen-like white printing, we will be demonstrating unparalleled levels of creativity including our latest Textures by Domino print solution showing the digital creation of three dimensional textured images. This adds another dimension to digital printing. It is no longer just about efficiently producing short and medium length production runs, it is also enabling our customers to offer innovative added-value design capability.’

Textures by Domino

Durst (Hall 6/D40) will show the Tau 330 UV inkjet press with the near-line Laser Finishing System LFS 330. Today, customers can individually configure the Tau 330 as a standalone solution, as an industrial scale production system with jumbo roll unit, or as a fully digital production unit with inline finishing. There are three compatible ink sets available for the Tau 330, one each to achieve a screen print- or flexo print-like quality, and one that complies with current low migration guidelines, for applications in the pharma and food industry.

It will also demonstrate the Durst Tau 330E, the economic version of the press designed for small and medium sized converters. This was engineered with particular attention to equipment cost while maintaining print quality and printing speed, allowing small companies to enter into digital label production.

Edale (Hall12/B05-3) will focus on its design and consultancy service with managing director James Boughton on hand to meet with prospective technology partners to discuss how Edale can support with web transportation systems and complex integration solutions. The company will also be available to discuss the features and benefits of its portfolio of flexographic and digital hybrid printing presses offered to label and packaging printers.

EFI (Hall 9/A40-1-2) will launch a new single pass press for corrugated which will be using a new water-based UV ink technology, enabled in part by the recent acquisition of colourant specialist Rialco in the UK. The company said that a whole range of presses will be launched using this new technology, including a machine for labels. ‘The new machine combines some of our great concepts,’ said CEO Guy Gecht. ‘It uses our experience of single-pass printing in a tough industrial environment from CretaPrint, the inline digital finishing capabilities of the Jetrion and the image quality of the VUTEk. And we will make it a lot more affordable than anyone else attempting to go into the digital packaging market.’

The recently launched Productivity Suite Corrugated workflow software will also be on show.

Epson (Hall 5/A1) has merged its wide format, label and textile businesses to create a new global, integrated Professional Printing Solutions division, which will see its official launch at the show. Its label proposition is to serve office, industrial and retail with products ranging from portable printer through to desktop to full industrial printing systems. Over the last six months, the company has launched 13 new printers and these will be demonstrated together for the first time at drupa. Labels will have a dedicated zone on the stand, where focus will be on the SurePress L-6034VW label press as well as printers from the ColorWorks and LabelWorks ranges.

Durst Tau 330 with finishing unit

Esko (Hall 8b/A23) will be joined by Enfocus and X-Rite to show their complementary solutions. The stand will be divided into several Inspiration Zones reflecting visitors’ activities to show a complete integrated workflow with all steps in the production process represented. The path will lead visitors through from ideation, brand management and design to shop shelf.

FFEI (Hall 10/B16-2) will showcase its end to end digital inkjet consultancy services. Managing director Andy Cook said, ‘At FFEI, we recognise that successfully integrating inkjet technology into a commercially viable solution requires an extensive range of expertise, IP and resources. Consequently, the barriers to entry can often be too high for many businesses, wishing to exploit the benefits of inkjet across a variety of sectors. He continued, ‘FFEI is one of the few partners that has the portfolio of technology and experience to not only help design the digital inkjet solution you need but also develop it into a product, manufacture and support it.’ Mr Cook and his team of digital inkjet experts will be attending the show to discuss real-world application opportunities for inkjet and to answer questions on its Graphium product range.

An inside view of the Graphium from FFEI

Focus Label Machinery (Hall 10/C10) will show the d-Flex digital inkjet press which incorporates the latest high speed, full colour Konica Minolta inkjet technology into the existing Reflex servo press with inline UV flexo print head, die-cutting, slitting and rewinding. Visitors will be able to see high quality variable images, overprinted in perfect register with UV flexo ink, then converted and rewound, all in a single pass with speeds up to 50 m/min.

Fujifilm (Hall 1 and 8b) will offer ‘value from innovation’ and is introducing a new brand name ‘Fujifilm Inkjet Technology’. Its main presence will be in hall 8b where amongst others it will show the Onset X Series printers and the Acuity LED 1600 II in the wide format zone of the stand, while in the package printing zone a new LED-UV inkjet press suitable for flexible packaging applications will be introduced. This new press is ideally suited for printing on the reverse of flexible packaging, and is powered by proprietary new image forming technology called EUCON (Enhanced Under Coating and Nitrogen purging technology). It runs at speeds up to 50 m/min in CMYK+W.

Also in focus will be the Jet Press 720S. Fujifilm has increased press up-time by 20% through software upgrades which have improved the efficiency and job handling capability of the press. An inline UV coater will improve appearance and protection and it will also show closer integration with finishing devices.

In hall 1, Fujifilm will be showcasing how its Samba printheads, VersaDrop jetting and Rapic anti-coagulation technologies have been combined to form the print engine of Heidelberg’s new B1 industrial inkjet press.

Global Graphics (Hall 7/B21 and C20) has launched software to improve the print quality of high-speed inkjet presses. The Multi-Level Digital Screening Engine was developed in response to requests from printer vendors for a cost-effective way to address the challenge of meeting the conflicting demands of higher speeds and higher quality on coated and non-porous stocks. It can be used post-RIP and supports the firm’s Harlequin RIP and others.

The latest version of its RIP, Harlequin 11, is available in two editions: the Harlequin Host Renderer 11, which powers the Digital Front Ends used in high-volume digital production environments, and Harlequin MultiRIP 11 for conventional and light digital production printing. It also has a number of new features for labels and packaging.

GMG (Hall 8a/B10) will share its colour management expertise with visitors.

The company has redesigned its proof media portfolio into two lines: ProofMedia Premium and ProofMedia Studio. The Premium line stands for seamless quality and reliable contract proofing, while the Studio range is targeted at creative professionals who need to rapidly produce accurate colors during the design process. As a Fogra development partner, GMG was involved in defining the new FOGRA51/52 characterisation data and, as a result, its new portfolio also includes proof media with OBAs (optical brightening agents).

Heidelberg (Hall 1) is presenting a whole new digital portfolio of presses. The ‘Fire’ product line includes theGallusDCS 340 inkjet press now renamed as the Labelfire 340, and a new B1 inkjet press, the Primefire 106 which features Fujifilm printhead technology and paper handling from Heidelberg’s XL 106 offset press. Aimed at packaging and specialist sheet applications initially, it runs at 2000 sheets per hour and will be offered with a CMYK+OGV configuration. Also renamed is the Linoprint CP/CV digital printing systems, now branded Versafire CP/CV, while the direct to shape 4D Jetmaster Dimension 250/1000 will now be known as the Omnifire 250/1000.

Highcon (Hall 9/C50) will be showing new additions to its range of digitalcutting and creating machines. The company will launch the Highcon Beam. As the most productive unit in the portfolio, the Beam can finish up to 5000 B1 sheets per hour and features the Highcon Axis web to print system.

Also making its debut, the new Euclid III comes with the option of adding variable data and 3D modelling capabilities. The 3D module with Highcon’s Rapid Layer Manufacturing technology offers customers a wide range of capabilities. Models are created based on any type of substrate, including recycled board and even used offset makeready sheets. Finally, the company will launch the Highcon Pulse as an entry level model, capable of cutting and creasing 2000 sph in B2 format.

HP (Hall 17) has a lot in store for label and packaging printers with a new high speed double engine press being introduced and upgrades for both the 20000 and 30000 presses. The new 8000 press combines two WS6800 presses, connected by a buffer control unit, to produce a speed of 80 m/min in Enhanced Productivity Mode, or 60 m/min in four colour mode. Printing using a ‘print one skip one frame’ type methodology, the maximum web width is 340 mm. Both engines have seven ink stations and the option to add orange, violet and green ElectroInks to the four process colours as well as the new Premium White, Fade Resistant yellow and magenta, Fluorescent Pink, as well as using the HP IndiChrome Ink Mixing System (IMS) for spot colours.

Also being launched at the show is a new lamination process, developed to run inline with the 20000 flexible packaging press for the production of stand-up pouches and other high performance packaging. This is the first of what is described as a new Pack Ready ‘eco system’ – a set of post-print converting technologies, developed and patented by HP and selected partners. The heatset laminate needs no curing time as a special resin is built into the structure. This then enables the Pack Ready Laminator to run inline with a pouch machine machine cutting production time significantly. The actual lamination unit will be produced by Karlville.

Also new for the 20000 is enhanced substrates compatibility for polyethylene and stretchable materials, for a wider range of high volume flexible packaging, shrink sleeve, in-mould and pressure-sensitive label applications, including lids and laminated tubes, and HP Premium White ink in 20 kg pails for industrial scale production. It will also benefit from the same colour management package as the WS6800 label press, including inline spectrophotometer for closed loop colour control.

An upgrade to the 30000 press promises a 30% increase in productivity in the production of folding cartons. For finishing, the Tresu iCoat 30000 coating unit now offers protective and spot varnish in one pass as well as new embellishment capabilities with gold, silver and other high viscosity flexo inks. New security features, such as micro text and barcodes, has also been added, as has an AVT 100% inspection system.

HP will also be introducing PrintOS, its new end to end cloud-based workflow platform. The system can be bolstered by the addition of apps for specific purposes. The first two apps Box and Siteflow, which are for job receipt and pre-press and shopfloor management respectively, and HP promises to have at least 10 apps available by drupa.

The HP 8000

Highlights from Hybrid Software (Hall 7a/F41) include Cloudflow Share, a cloud-based enterprise workflow solution, and Cloudflow RIP, a 64-bit scalable RIP for PC and MAC platforms based on Harlequin’s powerful Host Renderer kernel, with a custom user interface developed by Hybrid specifically for labels and packaging. Also being launched is PrintPlanner, a variable data options for digital packaging printing, while the PDF editor Packz will introduce warping and 3D facilities for shrink sleeves and cartons. Visitors to the stand will also be able to hear about Hybrid’s expanded gamut colour management as well as the latest developments in automated workflows, from MIS to digital output.

Kama (Hall 2/A15) is showing the DC 76 ASB automatic die-cutter with the latest in servo technology, and the newly developed KAMA FF 52i, billed as the first folder-gluer dedicated to short runs. This combined solution has been optimised for very fast job and format changes and electronic job tickets, and perfectly fits into the digital workflow by carrying out all the applications from the printed sheet to finishing folding box. The inclusion of AutoRegister and the SBU stripping and blanking unit, which works without the use of any tools, adds to the speed and flexibility of the process.

Kodak (Hall 5/F9) will unveil a next-generation continuous inkjet technology, dubbed Ultrastream, which it will make available to a wide range of partners in addition to using in its own products. It is part of a dramatic widening of the application range for the firm’s inkjet technology to include flexible packaging, interior décor and wide format. However, since unveiling Ultrastream, the company has announced its plans to sell the new inkjet division, along with its Prosper presses and Prosper S series imprinting heads.

The company is also deploying its Prinergy workflow as a cloud-based system and is launching a workflow for digital presses that it claims is set to become an industry standard. Customers will be able to choose whether to use a cloud-based or more conventional locally hosted model although cloud-based features such as automatic ganging ‘in the blink of an eye’ and automated job archiving would provide significant benefits.

Komori (Hall 15/D4) will be showing two new digital sheetfed machines, the Impremia IS29 B2 UV inkjet press, jointly developed with Konica Minolta (which sells it as the KM-1), and the Impremia NS40 B1 digital printing system, which uses Nano technology under licence from Landa Corporation. The Impremia NS40 has a speed of up to 6500 sheets per hour printing sheets of max 750 x 1050 mm in 1200 x 1220 dpi with water-based inkjet inks. It is offered in a basic CMYK configuration with additional colours as an option.

Konica Minolta (Hall 8b, A65-1-6) is set for the full commercial launch of the KM-1 B2 UV sheetfed digital press. KM recently unveiled PLS Print Logistic Services Germany GmbH as the first European beta site customer. The large 2400 square metres stand will be divided into business zones to cover the company’s complete production printing portfolio for markets, such as industrial inkjet, label printing and marketing automation. For personalised packaging, the bizhub PRESS C1100 will be shown with a Digital Flexo Cut system producing on demand full colour packaging. For label printing, the bizhub Press C71cf will be demonstrated complemented by an MGI JETvarnish 3DW and a DC330 finishing line from GM.

Kurz (Hall 3/D60) is presenting its Easy initiative, which aims to make life easier for processors. This includes the Foil Connect software program for calculating the most efficient foil usage, a new series of hot stamping foils with a wider processing window, as well as current methods for easier die mounting and for shortening set up times. For the cold foiling sector, the company will be presenting a new generation of cold foils with optimised processing characteristics. The Distorun system for processing single images and for efficient foil usage will also be demonstrated, as will the Digital Metal technology.

Some 1500 exhibitors from 50 different countries will visit Düsseldorf

Landa (Hall 9/A73-1-9) will conduct live demonstrations of all of its Nanographic printing presses, including the Landa S10 sheetfed press for folding carton and POP, the S10P perfecting press for commercial printing and the W10 web press for flexible packaging and paperboard. The company will also be introducing its Nano-Metallography, a ‘zero waste’ metallisation process that will halve the cost of metallised printing, demonstrated on a narrow web label press.

MGI (Hall 5/D21) is launching the JETvarnish 3D Evolution, a B1+ scalable sheetfed digital enhancement press, featuring a modular and field upgradeable architecture, digital foiling and an upgradeable inkjet expansion system, with three available substrate size options ranging from 52 x 120cm to 64 x 120cm and 75 x 120 cm.

Designed for packaging, the machine offers a blend of digital embellishments in the form of spot varnish, 3D raised varnish and digitally embossed foil, all in one pass. It incorporates pallet stacking, automated inkjet printhead cleaning, automatic feeding system as well as artificial intelligence-based sheet registration system.

Mimaki (Hall 9/A04) will bring its full product portfolio of solvent and UV printers and cutting tables. Of interest to the packaging printer will be the UJF-6042 flatbed printer in combination with the CFL-605RT flatbed cutting plotter, for the creation of packaging samples and mock ups as well as short runs of personalised or one of a kind products.

MPS will show its SymJet hybrid press during an Open House running during the show at its facility in Arnhem. The press has been developed in cooperation with Domino and was first unveiled last September in Brussels. The dates of the Open House are 1, 2, 3, 6 and 7 June and free transportation from drupa to MPS is available for show visitors. The bus will leave Düsseldorf at 10:30 and return around 15:15. Travel time is approximately 1 hour and 15 minutes.

Phoseon (Hall 9/D05) will be showcasing its LED curing solutions.

Primera will be present on the Nipson stand (Hall 8a/D46) to show its inkjet-based LX Series colour label printers as well as its CX/FX Series of digital roll to roll dry toner-based laser printers and digital finishers. These include the LX2000e industrial-grade colour label printer, the LX900e photo-realistic colour label printer and the LX500e colour label and tag printer.

Screen (Hall 8a/C11-1-4) will have the Truepress Jet L350UV digital label press producing a wide range of different label applications. It will also demonstrate a variety of new anti-counterfeiting, product tracking, security and full colour, individual bar code printing features. The press will be producing a wide range of different label applications along with a variety of new anti-counterfeiting, product tracking, security and full colour, individual bar code printing features. The company will also outline the latest advances in process automation, work efficiency and quality that are possible when its Equios software is used as a central hub to link individual Screen products and third-party systems.

Screen Truepress Jet L350UV

Scodix (Hall 4/D60) is launching a new digital enhancement press for the folding carton market. The E106 press prints B1 size sheets at speeds up to 4000 per hour. Delivering multiple print enhancements in one platform, the new machine features a number of Scodix technologies, including Sense, Spot, Braille, Digital Embossing, Variable Data and Foil. The company has partnered with Compact Foilers Ltd, which developed the foil system, and MABEG Systems GmbH for the paper handling system.

Siegwerk (Hall 3/A58) will be presenting its ink and services portfolio under the motto ‘We colour the future’. The company has announced that it is expanding its business into the inkjet market, initially for labels, followed by packaging applications. It has built a dedicated inkjet laboratory at its Technical Center in Annemasse, in France, to drive the development of inkjet inks that meet the requirements for printing process efficiency as well as the functionality of printed materials.

Steinemann (Hall 1/B18) is expanding its portfolio of UV varnishing machines in time for drupa. It will be presenting the new dmax 76, a narrower version for spot varnishing on paper and board sheets in sizes of up to 760 x 760 mm.

Tharstern (Hall 7/E28) will be showing specific applications and latest technologies from its team during ad hoc and scheduled demonstrations each day. Its focus on integration will be in an area hosted by CIP4 (The International Cooperation for the Integration of Processes in Prepress, Press, and Postpress Organization), which it has been involved with for a long time. Experts from Tharstern will be sharing best practice and demonstrating how customers can optimise processes and automation through effective MIS.

Tresu will be present in Hall 17 with its iCoat 30000 Twin. Featuring two coating units, this coating machine has been developed to run inline with the HP 30000 press to offer a complete digital printing packaging line. The company will also promote the compatibility and productivity of its integrated coating technology at the stands of other digital press manufacturing partners.

Trojanlabel (Hall 3/B31) will have three TrojanTwo mini presses printing flexible packaging including PP. The company will also have three of new TrojanThree over printing unit running demonstrations, showing printing on bubblewrap envelopes, corrugated and untreated wood. This runs at over 18 m/min printing in CMYK colour at up to 1600 x 1600 dpi. Both machines are memjet-driven.

Vivid Laminating Technologies (Hall 6/D58) will beshowcasing its range of laminating and print finishing solutions, which includes the Matrix Laminating System for digital and litho print, and the Easymount wide format laminators.

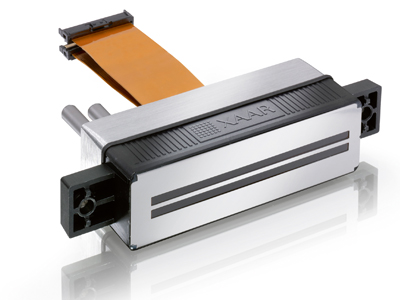

Xaar (Hall 6/C05) will present its range of inkjet printheads and products, announce a number of exciting new developments and launch a new Thin Film silicon MEMS technology platform. This includes the Print Bar System, the Xaar 501 printhead and the new Xaar 1003 printhead. The Print Bar adds single-pass inkjet capability to analogue web presses. Launched at Labelexpo last year, it allows users to take advantage of the benefits of digital printing easily and economically to deliver more creativity to their customers.

Xaar 1003 printhead

Xanté (Hall 5/C24) will show the Excelagraphix 4200 flatbed printer for short run corrugated packaging solutions, which is powered by memjet’s Waterfall Printhead Technology, employing a stationary print bar system that allows for single pass speeds of up to 416 corrugated flat sheets of 42 x 24 inches per hour.

Xeikon (Hall 8a/B20-1/3) is adding a flatbed die-cutting option to its Folding Carton Suite for nearline converting. The FDU is a 2000 sheets/hr system which can handle sizes from 400 x 400 mm up to 530 x 1000 mm and a maximum die-cut size of 490 x 700 mm. Substrate thickness range from 160 to 890 microns for paper, cartonboard and microflute corrugated board, making it suitable for completing offset as well as digital runs. Also for finishing, Xeikon will be promoting its Fusion technology concept which is still under development and set for release in 2017.

The Flint-owned company will be present in three halls and is also launching its Trillium liquid toner technology. The first press, Trillium One, is aimed at commercial applications, and was shown to the press during a pre-drupa press conference in March. This LED-cured printing technology offers 1200 dpi, running at speeds up to 60 m/min, 500 mm wide and requiring no substrate optimisation. The specially developed toner, named Tonnik, contains 2 micron resin particles and has a very high coverage.

X-Rite Pantone is joining Esko (Hall 8b/A23) to show its colour management solutions.

Zeller+Gmelin (Hall 3/C36) will be showing its current product range of inks for packaging and label printing. This includes the newly developed Uvaflex.digital UV lacquer series, which comprises gloss and matt varnishes intended for overprinting and finishing of digital print. All products in the range are available as low migration versions for food contact packaging applications.

Zünd (Hall 9/C05) will be presenting a variety of high productivity finishing solutions under the banner ‘Double your productivity’.