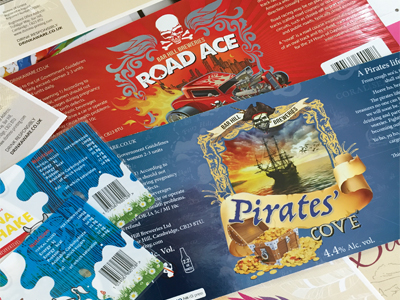

Inkjet label samples from Domino Printing Sciences

The time has come where inkjet is posing a viable challenge to other print technologies in the packaging space, both digital and conventional. Neel Madsen examines the many benefits of inkjet printing for labels.

Amongst the four key trends that Smithers Pira predicts will transform the digital print for packaging space is that inkjet will become the dominant digital technology by 2018. Judging by the amount of inkjet label presses presented at Labelexpo Europe last year, and also recent developments in packaging, we are well on our way to reaching that point. The speed is there and so is the quality.

In the label space

For labels, inkjet sits in the sweet spot between slower digital technologies and medium run flexo print with its time-consuming set up and plate costs. The technology has been around for a while in this market, with a steadily growing number of press installations, but now the momentum is truly building.

Inkjet label printing is entering the mainstream, not least evidenced by Labelexpo which had more than a ‘trail’ of inkjet presses; there were many varieties of the species, including the much talked about hybrid models, competing for a slice of the action.

In terms of print quality, the technology has particular advantages in the health and beauty markets due to the rotary screen look and feel of the all important white ink. Rotary screens for conventional printing are very costly and time-consuming to produce, require cleaning and are difficult to recover – all processes that are not environmentally friendly due to the chemicals involved. Inkjet can produce a similar look for a fraction of the price.

Scuff resistance and light fastness are other attributes that mean inkjet wins over electrophotography in certain markets. No need for lamination or varnishing which cuts production times. Add to that the high performance of the presses, the expanded gamut using a fixed colour set (CMYK+W and in some cases orange and violet) without using expensive spot colours that is now available, along with the greater flexibility in terms of substrates that can be printed on, and you have a winning combination.

Let’s hear it for inkjet

Baker Labels has been in the digital space for 10 years and after looking at inkjet for some time, decided on the UV inkjet Truepress Jet L350UV from Screen last year. Steve Baker, managing director, explained how it fits into his business, ‘The press not only boosts our production capacity considerably, but as a UV inkjet press, it also gives us the ability to produce great quality labels with good light, chemical and water resistance. We have a wide variety of customers with diverse label needs and this latest investment gives us the freedom to choose the best press to produce the best label for a specific application.’

Another recent owner of a Screen label press is Bill Hine, managing director of Hine Labels, who is impressed with the speed and the productivity it offers. The company is already producing digital labels on its Xeikon press. He said, ‘The Truepress has increased our digital label production speeds by 150%. The quality levels we have seen so far are amazing whilst also running at 50 m/min. The single pass white particularly produces outstanding ink laydown and opacity. Since investing in the new system we are very pleased with its high quality printed results, as too are our customers.’

Filling the gap

For label printers, adding an inkjet press to their capacity fills a gap and offers more flexibility without a compromise on quality. The Label Makers decided on a second Durst Tau 330 UV inkjet press at Labelexpo Europe 2015, but retains a mix of conventional and digital presses. When managing director David Webster spoke on the topic of complementing technologies at a panel debate last year, he said, ‘I strongly believe that there isn’t any one technology at the moment that can cover everything for us. We are still firm believers in conventional printing, but it really depends on what market you want to serve. You have to look at what your customer base is, what they are going to ask you to produce and then you offer them the right solution for that particular product and market.’

The new press has been installed with a chill drum allowing printing on flexible film and heat-sensitive materials, and variable data capability. Mr Webster commented, ‘We installed our first Tau 330 in 2013 and have found this technology to be fantastic in the lift and vibrancy that the inks have given to our customers’ labels, especially in the health and beauty markets where customers require the screen look. Industrial labelling is another area where we have been successful, customers love the durability and lightfastness that UV inkjet provides.’

At our ‘Digital print for brand success’ conference in November, Andy Walters of MPS Bristol spoke about the company’s investment in a Domino N610i press, citing the solid ink laydown and high opacity white, along with the fast speed and flexibility of the press as the main selection criteria.

‘Our asset management team looked closely at the engineering of the machine and we west chrisre really impressed,’ he said, and continued, ‘the abrasion resistance is remarkable as are the bright solid colours, the consistency and the colour matching. We can get to where we want in terms of colour very quickly and the press will print on almost all substrates.’ He also said the press is easy to work with and that it simply offered something different that fitted well with MPS’ brand customers.

Bas Hoijtink, commercial manager graphics at SPGPrints, with the company’s DSI UV inkjet press

Established technology

It may seem that inkjet is a new thing in labels, but in fact, UV inkjet label presses have been on the market for quite some time. EFI launched the first Jetrion press back in 2006 and SPGPrints brought the DSI press to market in 2008. Domino first showed the N600i label press at Ipex in 2010 at a time when Epson was first introducing the SurePress L-4033 series.

For owners of the EFI Jetrion label print system, the inline finishing and front-end integration with workflow systems are major plus points. Richard Rensen, owner of The Label Collective Group in the Netherlands, said, ‘We are one of the first label printers in the world to have digital printing and inline finishing in one machine. The new laser uses 95% of its power for die-cutting and only 5% ends up in the substrate. The benefit is that our labels come off the roll much more easily and are more suitable for further processing using automatic labelling machines.’

At Labelexpo, the focus was on the latest incarnation of the press, demonstrated with the Enterprise Packaging Productivity Suite configured for labels, flexible packaging and folding carton applications. ‘The Jetrion 4950LX LED press on display is the culmination of years of advanced research in narrow web production and LED inkjet technology. With nearly 200 presses installed worldwide, EFI is the market leader in narrow web inkjet technology and has helped customers worldwide achieve remarkable growth in digital label printing,’ said Ken Hanulec, vice president of marketing, EFI inkjet solutions.

The Durst stand at Labelexpo

Early bird

SPGPrints’ DSI (which stands for Digital Inkjet System) is a modular printer for labels and packaging, which first saw the light of day as a hybrid machine at drupa 2008, before developing into a four colour press shown at Labelexpo 2009. Today the press has up to 10 colours and features intermittent LED pinning between each station to ensure immediate curing and ink stability at fast speeds. It also has a chill drum to stabilise film substrates. It is available with low migration inks that meet the guidelines of the EuPIA and are compliant with the Swiss Ordinance on Materials and Articles.

Spanish label manufacturer Adamtec invested in the DSI last year to service its customers in the food, chemical and automotive industries. General manager Jaume Crespo said, ‘From the trial results, it was clear that DSI could give us the flexibility to offer variable data and the quality to deliver the consistency and high impact branding solutions. Another influencing factor was the performance of the inks, which gives us an opacity equivalent to screen printing and strong resistance needed for industrial situations.’

For McLoone, in the US, the DSI met the demand for high performance labels. ‘Industrial labels must perform for several years, perhaps resisting abrasion in the logistics chain, extreme weather and sunlight, water and corrosive chemicals,’ explained Keith Rosenthal, vice president of manufacturing. ‘We subject samples to accelerated weathering tests for outdoor durability, and a range of chemicals, including household and industrial chemicals and detergents. The ability of SPGPrints’ inks to withstand these conditions was a principal reason for investing in the DSI press.’

Smaller but perfect

For the smaller printing company, opting for an industrial-sized inkjet label press is often not an option. However, the benefits of inkjet can also be found in entry level machines, such as those incorporating HP’s PageWide technology, including NeuraLabel and Allen Datagraph printers, and those featuring Memjet technology, such as label printers from Colordyne, VIP Color, RTI Digital, Trojanlabel, iSys Label and Afinia Label.

Another cost-effective way of adding inkjet capability to your inventory is to fit (retrofit or from new) a small inkjet module to a conventional press. Industrial Inkjet (IIJ) has a number of modules on the market. These use Konica Minolta inkjet print head technology, and IIJ develops bespoke systems for customers in numerous industries.

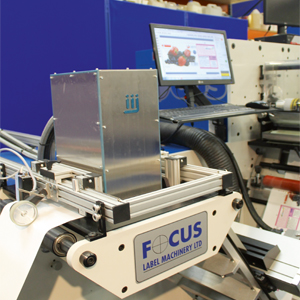

The d-Flex press from Focus Label Machinery incorporates an inkjet module from IIJ

After successfully piloting a high speed monochrome system at one of America’s biggest label companies, IIJ launched its HS range at Labelexpo 2015. With print widths as standard up to 520 mm and enhanced variable information software, it is ideally suited to printing of variable text, small 2D barcodes and multi-page PDFs at speeds of over 160 m/min, amongst the fastest on the market today.

In focus

Focus Label Machinery manufactures the d-Flex system, which features the ColourPrint 142 iS print engine from IIJ. This press offers inline converting that includes a flexo printing or coating unit and full rotary die-cutting as well as cold foiling and slitting to produce finished labels. This flexible option can be used independently as a standalone production machine or as a converting line for pre-printed rolls of labels.

One UK converting company has recently installed a d-Flex 250 UV digital inkjet press for various applications, including labels. The 250 mm wide press is equipped with a 212 mm inkjet facility located between two UV flexo heads, where the first flexo station is used to print opaque white, followed by variable data printing via inkjet, then varnishing on the second flexo station. Jobs that were previously produced slowly using thermal printers are now being completed in a fraction of the time on the new press, explained Focus sales manager, Antony Cotton.

The modular inkjet system is available in 142, 212 and 330 mm wide versions, with running speeds of up to 70 m/min. In addition to process colours, a white option is also available, with LED curing for printing onto transparent filmic substrates. Software and RIP with variable information and colour management is included as part of the overall package.

Mr Cotton commented, ‘The d-Flex offers hybrid inkjet single-pass print technology, with an industrial performance, suitable for general and specialist label manufacturers alike. With increasing pressures from buyers to order less labels at more regular intervals, the d-Flex offers an effective method of producing short run, digitally printed labels at an affordable level.’