Xeikon X-800 digital front end combines pre-press, data processing and press operation functionality

Without the right tools, getting more short runs to print creates bottlenecks and increases costs, making digital uncompetitive. Fortunately there are many software tools available that take time and cost out of admin and pre-press functions. In fact, there is an awful lot of choice as workflow has become the really hot topic, says Sean Smyth.

An obvious, but sometimes unconsidered, issue with digital label and package printing is the need to present correct artwork to the press when it is needed. As the average run lengths are lower than with flexo or offset litho so more jobs will be needed in shorter time.

Esko is the market leader in packaging design and pre-press software and workflow, and is continually developing its products, releasing upgrades each year and seeking customer feedback to identify new features required. One forum is the EskoWorld events that bring customers together to network and listen to product managers detailing the latest developments and product roadmaps.

Powerful portfolio

Esko software handles all aspects of packaging and label design, pre-press and production for both digital and analogue production, from concept to finishing. The software portfolio includes ArtiosCAD for structural design; ArtPro and PackEdge are powerful packaging editors while DeskPack is a collection of packaging pre-press plugins for Adobe Illustrator and Photoshop.

A very useful function is the use of 3D imaging, combining the structural and graphics components, with the capabilities being broadened to include store visualisation and photorealism. Esko provides digital front ends for several digital presses, including HP Indigo and Domino.

Each program in the suite can be combined with the Automation Engine or WebCenter to become very powerful and productive tools, with MediaBeacon providing digital asset management helping brands control their content effectively. Some of these tools can be used in commercial graphics applications, where the automation tools are proving to be popular outside the core packaging users.

User experience is key

Changing end user demands means print companies are moving into new areas and Esko is continually upgrading its products with version 14.1 released in July. The updates follow four broad themes: automation and how to apply it; standardisation; user experience for those with limited print/ packaging expertise; and supply chain integration, moving pre-press from an island into mainstream business activity.

The graphic editor software is developing beyond just make-up. It needs to fit in with workflow tools to help remove errors and much development is to automate the output, allowing the creatives to be creative. HTML5 is replacing Java for browser and mobile viewing on smartphones, for Google or iPhone. This supports greater 3D functionality integrated as a tool rather than a viewer, with new store visualisations using a virtual environment generator. There are new templates of empty stores with dynamic lighting and powerful physics emulator that can be used in conjunction with photo-realism software to provide marketing collateral and HD video output.

The power is the link with Automation Engine, supporting the changing role of the editor toward a checking and exception handling function. A key strength is the links between components, based around the Automation Engine. Over 2000 customers use the software to automate routine, repetitive tasks, with the focus on integration and connectivity across the supply chain. New features put the effort on improving quality, using KPIs to track productivity while an auto health check and improved indexing boosts database performance.

Esko is moving toward using smart technology in its software, developing new user experience to make programs simpler to use, and so increasing productivity. Interfaces are more intuitive, there are fewer static menu and dropdown selectors, rather tool palettes are made available only when relevant to the tasks being carried out, so the work area is less cluttered.

While packaging creation, pre-press and management is rather more complex, the user experience for new and future operators will be a key determinant of acceptability. The transition to a subscription SaaS model lowers upfront cost, making the software licence an operating cost rather than a capital spend, with support included in the subscription meaning users will always have access to the latest version.

Digital front end

Xeikon is also developing its software offerings. The X-800 digital front end now incorporates the latest RIP technology available from Adobe, supporting the Adobe Mercury RIP architecture. This enables digital printers to process jobs in the fastest, most flexible and secure manner possible. The release makes complex tasks, such as handling multiple transparent print layers, high level security and brand protection features demanding the highest possible resolution, and sophisticated variable data work, faster and easier.

When the Adobe PDF Print Engine is configured in the Adobe Mercury RIP architecture labels, folding cartons and other packaging applications will benefit from streamlined processing time in generating ready-to-print bitmaps. The processing of jobs occurs in parallel and can be load-balanced to ensure that no CPUs are idle while files are waiting to be rendered. Mercury can be configured to dynamically allocate some CPUs to a rush job, while other CPUs will continue to work on processing the routine work.

The RIP architecture complements Xeikon’s X-800 unique built-in metadata module, which enables variable data jobs to be defined entirely on the press. To enable tracking of production from print to delivery or to prevent counterfeiting, the X-800 allows the dynamic addition of production data or other variable elements such as sequential numbers or barcodes to already RIPped documents. The X-800 also features automatic printer calibration, density control and registration adjustments for excellent colour stability and consistent output quality, and even allows post-RIP colour adjustment during printing, minimising downtime while offering great flexibility in ensuring continuously consistent quality.

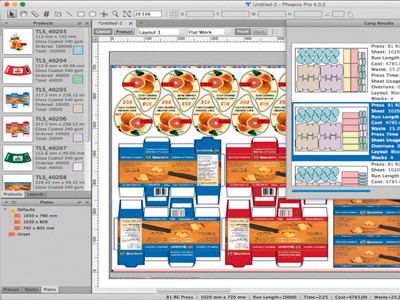

Fujifilm has entered into a distribution agreement with Tila Labs to incorporate Phoenix imposition and planning software into its portfolio

More options for digital

FFEI is pushing its Graphium Label Production Workflow, which can also be configured for other digital print systems. This offers a highly automated system designed to optimise either flexo or inkjet production, and hybrid systems. There is full JDF functionality and automating routines with the potential of eliminating manual intervention from a submitted file to the finished product. It will check the cutter guide to determine if there is a standing cutting die available. Using flexo or inkjet when both are available can be selected to optimise production time and cost, along with finishing tooling to minimise waste.

Fujifilm has a new distribution agreement with Tilia Labs to incorporate Phoenix imposition and planning software for packaging applications into its print production solutions portfolio. This is a JDF-based platform that integrates with Fujifilm’s XMF Workflow to provide increased automation and production efficiencies for packaging, labels and tags. It offers a wide range of imposition features including irregular shaped step and repeats, automatic artwork to die layout alignment and mark management. The software’s planning capabilities optimise the way jobs are ganged for printing based on minimising waste or maximising print speeds. This functionality supports true shape nesting and automatically provides users with different options to arrange jobs. Phoenix also enables print service providers and converters to quickly generate accurate job estimates and drastically reduce preparation time and waste.

There is a lot of software available designed to make label production more efficient and effective. Have a look at the latest offerings – you may be surprised with what you find to solve your pain points.