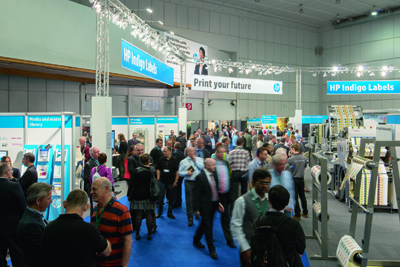

Promising to fulfil your every technology wish, Labelexpo returns to the exhibition halls in Brussels on 29 September to 2 October. Where digital was once confined to one hall, almost as an afterthought, the technology is going to dominate the 2015 show. By Neel Madsen.

Whether it is making steady inroads or showing exponential growth depends on whom you ask, but digital is most definitely no longer a ‘complementary’ technology, but a strong force in its own right.

Inkjet first truly made its presence known at the 2013 show, but with so many of the conventional press manufacturers announcing hybrid machines, we can look forward to a 2015 edition where throwing dots onto the substrate will take centre stage.

Meanwhile, the latest for package printing will be coming from digital electrophotography with wider and faster presses producing high quality flexible packaging and folding cartons. In the Packprint Workshop, Xeikon will showcase carton printing on its 3500 press, while Nilpeter’s conventional FA-4* press will be running a number of sachet jobs.

The Label Academy will be presenting a Master Class on digital label and package printing with input from HP Indigo, Xeikon, Domino, Esko, Avery Dennison and AB Graphic International. Over four hours, this will identify the opportunities, present the different technologies from presses, materials and finishing solutions and cover the key processes. An optional live demonstration of digital printing will be held on the show floor. A concurrent session on conventional printing will provide an overview of letterpress, lithography, flexography, screen, gravure and combination printing.

The show has this year expanded into eight halls at the Brussels Expo to accommodate the 600+ exhibitors who will be on stand to show their wares and launch their latest innovations. Let’s look at what you can expect to see.

AB Graphic (stand 6A37 )will have its Digicon 3 converting line on stand. This was launched exactly one year ago. ‘With everyone demanding shorter lead times we have seen a clear increase in the automation modules for the Digicon Series 3 allowing customers to benefit from reduced set up times,’ said sales director, Tony Bell. ‘The three main finishing elements take on average 10 minutes to set up, but with a combination of our auto Plate/Die Load, Autoslit and auto Iscore, set up times can be reduced by approximately nine minutes for each job change.’ The company will also launch a heavy duty flatbed hot foil head with a rotatable foil feed to allow for feeding foil along and across the web direction. Male/female embossing can be performed simultaneously with the foil process and impression capacity has been increased to 50 tons.

Afinia Label (stand 8A29 )will be showing its full range of digital labelling solutions. Taking centre stage will be the DLP-2000 Digital Label Press, a memjet-powered full colour 1600 dpi label production and finishing system. It will also launch a semi-automatic bottle applicator and the Afinia H800 3D printer.

Avery Dennison (stand 5A31) promises to introduce ‘a number of significant innovations designed to drive sustainable growth’. This includes a new emulsion acrylic, general purpose adhesive for paper; Aqua Opaque, a solution for the wet opacity issues in wine & spirits labels; AeroDress, a pressure-sensitive solution for aerosols, and a new bio-based PE product to help end users meet their sustainability goals. Also being presented is the Select Solutions Portfolio, which offers application-specific constructions as well as custom-engineered solutions to match exact customer needs. This collection has 100,000 potential constructions via the company’s Mix & Match service, and 15 application-specific portfolios.

For AVT (stand 9C05), the show will be the first outing for the new joint portfolio of solutions with strategic partner Erhardt+Leimer since the alliance was announced. Visitors will see the premiere of Helios S Turbo, an inspection system designed to help production lines reach maximum potential through increased printing and rewinding speeds. There will also be a new quality control engine for inkjet digital presses, as well as extended automation solutions, such as the Offline Setup tool and SolidProof offline proofing solution. For fully automated inspection and verification throughout the entire digital printing process, AVT offers a combination-product solution that includes the ZeroSet Automated Inspection Workflow, which addresses market needs for inspection on shorter runs and better support for digital presses.

Chili Publish (stand 4C65) returns for the second time to show its Publisher online editor, which in addition to the powerful design and editing functionality, also includes features that let users achieve cost savings on artwork creation and experience an increased speed to market. Its products can also be seen on partners Esko, Cerm and Xeikon’s stands.

Colordyne Technologies (stand 9C65) will show the 3600 Series Production Class platforms with new Enhanced Efficiency Mode that runs at 99 m/min at 1600 x 1175 dpi, in comparison to the existing 84 m/min at 1600 x 1375 dpi. Also on show will be the newly launched 2600 Series Mini Press from the company’s Commercial Class line of products. This prints short run digital labels at 18 m/min at 1600 x 1600 dpi. The dually supported frame and servo driven web handling system allow customers to produce longer run lengths, like the Production Class system, but with a smaller footprint.

Comexi will present the new Nexus L20000 water-based lamination and coating machine in the HP Indigo hall. The machine has been developed for flexible packaging applications specially designed to complement the HP Indigo 20000 Digital Press, and runs at speeds up to 150 m/min. Available in inline or offline configurations, it offers solvent-free lamination to help flexible packaging converters shorten time to market, as well as a reduction in waste and environmental impact.

Dantex (stands 4A40 and 8C40) is launching the PicoColour II high speed UV inkjet digital label press, which has been developed together with JF Machines, now a part of the Dantex Group. The press offers a printing width of 210 mm and runs at speeds up to 35 m/min. It is available with CMYK + white, with the ability to use the white in a single-pass application. In conjunction with optional corona treatment, it can be used for paper as well as filmic based media. The press can be seen on the stand in hall 4 where the Screen Truepress Jet L350 UV will also be running.

Delta ModTech (stand 6E51) will feature a custom converting and heat seal pouching system, which will be running a complex patch product during the show. The system will feature a variety of processes including rotary die-cutting, embossing, precise part placement and heat seal pouching. Other Delta ModTech systems may include additional capabilities such as semi-rotary, full rotary and laser cutting.

Domino Printing Sciences (stand 9A60) will feature the seven colour N610i, not only as a standalone roll-to-roll label press, but also as a modular hybrid solution integrated with an ABG Digicon three incorporating flexo, varnishing and die-cutting modules. Also featured will be two K600i digital print modules, which will be integrated onto a Graphi Mecc web inspection system to print black variable data, and a new digital foiling solution. Based on real metallic foil, this cold foil solution uses the K600i to print a digital adhesive and create the image area prior to UV curing and delamination.

Durst (stand 8B26) will launch its Tau 330 E at Labelexpo. This is a budget priced, single pass, UV inkjet label press with new high pigmented UV inks for reduced ink consumption, especially designed for the small and medium sized label converters. It is available in print widths of 200 mm or 330 mm, with four (CMYK) or five colours (CMYK+W) offering a print speed of up to 48 m/min and the choice of two print resolutions: the standard print mode at 720 x 360 dpi and the HD print mode at 720 x 1260 dpi. The standard Tau 330 press will also be shown, in this instance running inline with a finishing solution from converting specialist Printum GmbH (on stand 6C63).

Edale (stand 7D39) will show the Graphium, a fully integrated solution that combines workflow, digital and flexographic print with automated finishing, delivering a highly productive solution for the manufacture of short, medium and long run labels, packaging and cartons. ‘Edale has been involved in the design and development of web transport technology for single pass inkjet since 2002 and can observe the commercial potential that Graphium holds for the future of the packaging industry,’ said James Boughton, managing director. ‘Developing the web transport, hybrid print and finishing technologies for Graphium over the last two years with FFEI has resulted in significant productivity advances.’

EFI (stand 9C40) will show its narrow web label production presses and complementary software designed to optimise workflow and accountability. This includes the EFI Jetrion 4950LX LED digital label production system, with white ink and inline finishing. This platform broadens the stock options available to label converters with its ability to work with heat-sensitive and difficult materials. Also shown will be the latest Fiery ProServer digital front end, Digital StoreFront web-to-print and the EFI Productivity Suite that encompasses Radius MIS for labelling and packaging specialists. EFI GamSys MIS/ERP offers a modular solution that integrates with workflow operations, while EFI Metrix enables users to create cost-driven layouts via automation. Esko’s stand will also be showing its Automation Engine modular workflow pre-press server integrated with EFI Radius.

Epson (stand 9A50) will present the SurePress L-6034VW incorporating PrecisionCore linehead and LED-cured UV ink with inline digital varnish and high opacity white ink, and the seven colour SurePress L-4033AW aqueous inkjet label press. From its ColorWorks range, the C3500 will be shown for the first time , while the latest C7500 with PrecisionCore linehead will be printing quality labels on a wide variety of materials with and without rewinder capability. From the LabelWorks compact range, comes the SureColor SC-S 64 inch wide format printer for a variety of small to ultra large labels, in cut step-and-repeat formats, for hard-wearing stickers and decals on a wide range of self-adhesive substrates. Finally, Epson will unveil a new printer for enhanced packaging proofing capabilities.

Esko (stand 4C20) promises ‘a big splash’ at the show where it will present its full range of solutions designed to help label and packaging converters build consistency and flexibility in their production workflows. ‘Labelexpo Europe is always a great show for us,’ said Armand Gougay, VP EMEA. ‘We will share our expertise and suggest how to improve profitability by implementing smart pre-press, automated workflow, best in class flexo, colour management and systems integration across their entire business. Our focus at the show will be to demonstrate how smart prepress solutions help any label and packaging converter to grow their business.’

Focus Label Machinery (stand 7D25) will run live demonstrations of its latest models with servo and digital solutions at the forefront, for the short and medium print run business. The d-Flex digital inkjet pressincorporates the latest high speed full colour Konica Minolta inkjet technology into the existing Reflex servo press with inline UV flexo print head, die-cutting, slitting and rewinding. Visitors will be able to see high quality variable images, overprinted in perfect register with UV flexo ink, then converted and rewound – in a single pass with speeds up to 50 m/min.

The Folex Group (stand 9C12) will show its newly developed films for all laser printers, HP Indigo presses, and inkjet machines. A special highlight is the SPNR water-resistant, high gloss PP film with extremely good drying properties for a brilliant colour print quality on the latest generations of high-speed inkjet printers. Another new feature is Folex Tack range, which has an adhesive-free adherent layer for easy adhesion, residue-free removability and multiple re-use of labels. It is available for water-based inkjet printing, UV inkjet printing and HP Indigo systems.

Fujifilm (9A34) will be featuring a dedicated label workflow solution, the UVivid range of narrow web inks and ancillaries, and its hybrid inkjet printer, the Acuity LED 1600, which will be used to highlight how users can produce short run labels and prototype packaging samples, taking advantage of the printer’s spot varnish capability.

Gallus (stands 5B28 and 5C31) will present the recently launched DCS 340modular digital converting system, which features an inkjet printing module integrated into a Gallus machine platform. Developed as a joint venture between Heidelberg and Fujifilm, the system offers a native resolution of 1200 and combines the strengths of digital printing with inline finishing for roll to finished die-cut label in a single production operation.

GMG will partner with Epson (stand 950) to show its colour management solutions for labels and packaging. Using the Epson Stylus Pro 4900 and Stylus Pro WT7900 proofing printers, as well as a new proofing printer, the company will produce packaging proofs on a wide range of materials, including transparent film to show its capabilities.

Grafisk Maskinfabrik (stand 9A40) will launch a combination print and converting machine with flatbed hot stamp and screen modules. The machine is only six meters long and has semi-rotary die-cutting and a flexo printing station. Also new is the LC330 Laser Compact machine, which is equipped with flexo varnish, cold foil/super gloss and a knife box. GM’s mini series of inline converting systems for digital presses has been upgraded with cold foil/super gloss capability. The unit now supports the HP Indigo WS6600 inline calibration modes (web reversing). The company is also launching a new inspection slitter rewinder.

Grafotronic (stand 11P85) will be exhibiting a range of new innovations, including the new DCL-SERIES, a fully modular digital finishing machine with flexo printing and a combined semi-rotary/full rotary die-cutting unit. Each module is servo driven, works independently and it is fully upgradeable. It will also show the newly updated R-Series, a pharma machine for 100 % re-inspection. This compact machine has a high speed servo buffer that allows re-inspection in 200 m/min. The HI-Series for 100% inspection has a modern design with an innovative web path. It has been equipped with a new Grafotronic automatic knife positioning system. Also being shown will be the new CLD-Series, a module based die-cutting machine with new quick change features on every part from unwind to rewind.

HAPA (stand 8A24) is set to introduce the Universal UV inkjet label printer, LP 834. This UV drop-on-demand, CMYK+W and precision-inset printer is designed for a variety of blank or pre-printed web-fed substrates, opaque or transparent. It handles material widths up to 340 mm, and prints at speeds up to 54 m/min in single or multi-colour CMYK, or spot and lacquer application. The tension on the integrated material rewinder is adjustable, so that printed labels leave the system production-ready. The module concept allows for the individual composition and docking of components and options, and a small machine footprint. In addition, Hapa’s division Hapa Ink will be showcasing its products on several Hapa systems, including white printing on the Universal label printer.

Taking over the entire Patio hall, HP Indigo will be showing visitors how to ‘print the future’ with its range over digital labels and packaging presses. These include the WS6800 digital press for narrow web applications, with new advanced colour management tools and inks, and the mid-web HP Indigo 20000 for flexible packaging and high productivity of label and sleeve applications.

The company will be offering an insight into how full integration with leading industry vendors offers complete workflow automation to maximises productivity. Visitors can experience the entire process from idea and design stage, through pre-press, substrates range/flexibility printing and to finishing capabilities.

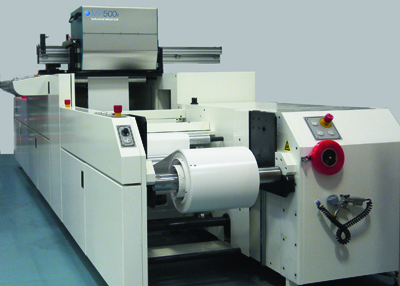

Industrial Inkjet (IIJ) (stand 9C70) will be launching a new 600 dpi high speed mono range. With print widths up to 520 mm, the new models are suited to printing of variable text down to 2 point fonts at over 50 m/min and are powered by Konica Minolta inkjet technology. These units print full variable images in black, white, varnish or spot colours, as well as security inks such as IR black or UV fluorescent.

IIJ New mono range MP500i

Innovia Films (stand 4B48) has produced its first top-coated BOPP label films that are proven to be food contact compliant under European Union (EU) and Food and Drug Administration (FDA) regulations – UltraFoil CFA (clear) and WFA (white). Both films comply with the applicable EU and US legislation for most applications involving direct contact with food across most food types. The compliance also covers a broad range of food use conditions, such as ambient temperature filling and storage, chilled use, frozen conditions and warm fill.

INX International (stand 9C18) will show its full range of inks for flexible packaging, folding cartons and labels. At Labelexpo in Chicago last year, the company also introduced the NW210 inkjet UV digital narrow web press for label converters, direct mail and packaging printers considering or in the midst of transitioning to digital printing. This is powered by the JetINX printhead drive and ink recirculation system to achieve UV LED cure single pass output at up to 80 fpm at a maximum printing width of 210 mm.

Impression Technology Europe (stand 8A19) will show the new ComPress LF4 digital label cutter, which has been developed for performance and value, and to provide a finishing solution to the ComPress LP4 LED dry toner label printer. Including contour cutting, waste removal and a slitter in a single compact device, the LF4 combines the latest tracking technology with robust, industry standard engineering.

Konica Minolta (stand 8C54) will be entering the industrial printing market with its digital label press, the bizhub Press C71cf, at the beginning of 2016. Demonstrated at the show, the new toner-based machine runs at 13.5 m/min with a maximum paper width of 330 mm and 1200 x 1200 dpi resolution (with optical resolution of 3600 dpi).

Label Traxx (stand 9A10) will introduce version 7.2 of its MIS, which has a number of enhanced features for integration with strategic partners. This includes the ability to estimate and order magnetic tools electronically from RotoMetrics, and to pass customised digital lead-in and lead-out data to Automation Engine, which can be automatically printed at the beginning and end of a run to simplify the job of the finishing department; along with new enhanced ink pricing for HP WS6800 and white plus inks to handle ‘can’ charges, and quote for inline priming. The new version can also monitor folders so that when a file is dropped into that folder, it will load automatically into the MIS – for example, artwork files can be dropped into the product image, approved proofs could be dropped into the job ticket or die lines dropped into the tooling record.

Marabu (stand 11D35) will present its new solvent-based Mara Jet DI-SX Plug&Print inkjet inks for the EcoSolMax 2 generation of Roland printers. The high-grade pigmented ink system provides silver, gold, bronze and other pearlescent metallic effects as well as a nickel-free yellow and Light Black. In combination with the glossy water-based Mara ShieldWA-FXG liquid coatings, these are fully resistant to abrasion.

Mark Andy (stand 4C45) will use the show to introduce its Digital Series press platform to the European market. This is a hybrid system that integrates full colour, quality digital printing technology inline with flexo printing, converting and a variety of label and package decoration options. Printing CMYK+W at speeds over 76 m/min, the system combines the economies and productive advantages of digital workflows, digital inkjet and flexographic workflows delivering a dynamic approach to vastly minimise job changeover times and maximise SMED principals of lean production.

Michelman (stand 9C20) will showcase its DigiPrime printing primers formulated specifically for HP Indigo presses. This is a line of water-based, HP-recommended/certified primers that improve ink receptivity, rub resistance and image quality on most types of paper, plastic, metallic and film substrates. A new introduction is the DigiPrime 680, formulated specifically for use in the inline priming (ILP) unit of the HP Indigo WS6X00 series.See also’Substrates’ on pp 56-57.

Mimaki (stand 8C52) will be displaying new products for the label market, which can be created with its range of printers. Highlighted will be labels embellished with Eco-Solvent Silver Ink, alongside flexible and rigid labels for safety applications, such as fire exits and assembly point indicators, delivered on the UJF-6042. On the stand will be a variety of large format printers, including the CJV150 Series and the UJF-6042 A2 Format UV LED flatbed printer.

Mimaki CJV150 label applications

MPS (stand 11C20) will unveil a new hybrid printing solution, the EF Symjet, which encompasses a flexo press with an integrated inkjet module that can print up to six colours and white as an option.

Newfoil Machines (stand 7C41) will present the Newfoil 3534 Servo flatbed hot stamping, embossing and die-cutting machine, which has been developed to be compatible with the 330 mm wide digital and flexo presses. The maximum web width of the press is 340 mm, platen size is 310 x 270 mm and the top speed is 75 m/min. The control system has been further improved by the use of the latest series of servo drives and software advancements, while the resolution of the touch screen control panel has been doubled.

Nilpeter (stand 7B35) is re-entering the digital arena with the launch of the Panorama DP-3 five colour UV inkjet unit. This has a maximum printing width of 322 mm and prints up to 50 m/min on paper or filmic substrates from 90 to 350 microns. High definition UV inks are used for CMYK, with opaque white ink as standard for printing transparent films and metallic foils. The print engine delivers colour output using single pass 600 dpi piezo printheads with four level greyscale imaging. A minimum droplet size of 3 picolitres allows small dot halftones and the digital front-end uses advanced workflow management system.

OKI (stand 9C24) is launching a flexible new printer, which the company says has been designed to meet key industry needs and plug a long-standing gap in the market. Printing on a wide selection of paper and synthetic media, the new label printing technology utilises LED technology and can print transparent white-under labels and paper white-over labels.

Omet (stand 6C49-C53) will have the XFlex X6 Digital on show. The 430 mm wide flexo press features the four colour digital inkjet unit JetPlus enabling variable data, short runs or samples to be printed.

Tilia Labs (stand 4A52) will show version 4.4 of its Phoenix imposition and planning software for packaging application. Highlights include new Alignment Tool features, drag to duplicate items, single click item swapping and a hot key for applying marks to a single product instance. The release also adds support for snapping artwork to dies using PDF layers.

Roland DG (stand 9F46) will present a number of its UV LED digital printers, which are suitable for proofing, prototyping, micro-runs and short runs on a variety of substrates. The printers are available in widths up to 163 cm and use up to six colours: CMYK, white and clear. The transparent ink can be used to create matt, glossy and relief effects, including Braille and structure printing. The company will also show its range of eco-solvent printers, which feature white and metallic inks.

Screen Europe (stand 9B30) will demonstrate the latest model of the Truepress Jet L350UV inkjet label press with new software, hardware and finishing features. This model will be featuring new ‘vivid colour’ extended gamut, JDF-enabled job control software and inline/offline finishing. The new link to Cerm MIS allows JDF communication to the Screen Equios digital front end to eliminate many repetitive manual tasks and automating planning and step & repeat routines. The Screen JetConverter L350 also on show is a modular finishing solution offering both inline and off-line operation. It is equipped with varnishing, lamination, die-cutting and slitting. Also new is Vivid Color Mode which allows the press to extend the colour gamut that can be achieved from the existing ink set, and a newtext resolution function on the DFE which offers HD quality text sharpness by reducing ink spread across the whole job or on selected elements.

Sei Laser (stand 9C57) is introducing the Labelmaster, a digital inline converting platform featuring up to four laser cutting heads. The modular solution can be customised on purchase or afterwards with a series of optional retrofitted.

Shuttleworth (stand 8A33) will show the latest label industry specific developments to its integrated MIS package. These include the job tracking functionality Milestones, for quick and easy to viewing of job status, the latest production scheduling module, including new options for automating the production planning process, a new mobile stock app, which allows users to update stock transactions using a mobile device with bar code scanning if required, and a fully integrated CRM package, which includes a mobile app enabling anyone working remotely to access and update vital information. The company will also be using the show to demonstrate how it can deliver bespoke software solutions through Shuttleworth Plus.

Spartanics (stand 9C35) will be presenting live laser die-cutting demonstrations, including the ability to run a wider variety of materials. The system has high-speed laser die-cutting capabilities, and comes equipped with the Spartanics Fastline laser cutting software which extracts die lines from vector files with a simple click of a button. Its solutions can also be seen as part of an inline system integration on the Durst Tau 330 LFS (stand 8B36), while the Digital Galaxie semi-rotary laser converting system will be showcased on stand 7A15. Finally the NW210 UV Inkjet Narrow Web Press will be featured on the INX International (stand 9C18). This is able to digitally print and laser (or semi-rotary) die-cut up to 210 mm wide and reach printing speeds of up to 24 m/min with a variety of finishing options.

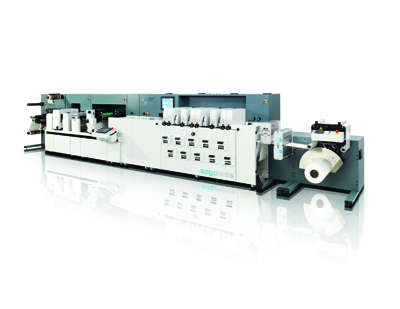

SPGPrints (stand 8A10) will present live demonstrations to show the potential of its DSI digital UV inkjet press and workflow. Available in widths from 135 to 530 mm, the DSI features CMYK inks, intermediate inline LED pinning stations and chill drum as standard. In addition to the four process colours, the press can be specified or retrospectively extended with up to six extra stations, including orange and violet to make 90% of the colour gamut, digital white with industry-leading 93% optical density, and a digital primer. A full range of semi-rotary converting options can be included inline. SPG’s proprietary UV inkjet inks offer UV, chemical and scratch resistance, and include low migration options, fully compliant with safety standards for safe food/pharmaceutical packaging.

SPGPrints’ DSI UV inkjet label printer

Sun Chemical’s digital inkjet division, SunJet (stand 5E45), will be highlighting its latest capabilities and expertise in UV curing inks which provide optimum image quality and reliability on a wide range of substrates. Demonstrating its understanding and expertise of food safety regulations, SunJet will also present its range of compliant inkjet solutions for printing onto the non- contact side of primary and secondary food packaging applications. Also on show fromSun Chemicalis SunColorBox, its set of applications and services to implement a digitally colour managed workflow. Tools in the SunColorBox include colour audit, to rationalise and digitise a converter colour palette; SunDigiProof for onsite, on-demand colour accurate proofs; SunDigiGuide, a colour standards book; SunMatch, for full digital colour communication between ink supply and customer networks; and PantoneLIVE. Finally the laser marking coating solution, SunLase, will also be shown.

Tresu Group (stand 7D53) will showcase its coating technology for digitally printed folding cartons via a tabletop presentation. The Tresu iCoat 30000 TWIN includes two flexo units capable of applying spot, partial or full surface coating immediately after the printing stage. Specifically designed for inline integration with the HP Indigo 30000 Digital Press, it runs at a minimum of 5000 sheets per hour on board substrates between 180 and 500 gsm. It also features corona treatment, quick-change sleeve tecnology and the ability to switch from UV to aqueous varnish within a few minutes.

Workflowzwill be present on the Tilia Labs stand 4A52 – see above.

Xeikon (stands 9C50, 9B50 and 9C60) will unleash its Cheetah technology in the form of the newly designed CX3 press, which will be commercially available with orders being taken at the show. The five colour dedicated label press runs at 30 m/min printing at a resolution of 1200 x 3600 dpi with FDA approved toners on substrates between 40 and 350 gsm, 200 to 330 mm in width. The fifth colour station can be used for spot colours, security toner or one-pass opaque white.

Xeikon Creative Colors silver samples

Also running on the stand will be the Xeikon 3300 flagship narrow web label press, which will be printing wine, health & beauty, food and industrial applications, while the Xeikon 3500 press, dedicated to folding carton, will be demonstrated in the Packprint Workshop. New introductions at the show also include two new toners: MatteSilver and PalladiumSilver, the first products in the new Xeikon Creative Colors toner group; and the Xeikon X-800 4.0 DFE with the next generation VariLane impositioning tool and full support for the Adobe Mercury RIP Architecture and ColorKey.

X-Rite (stand 7A10) will focus on the recently launched version 2.6 of ColorCert: X-Rite Edition. This is a cloud-based standards-compliant and specifications management solution for the exchange of colour data in real time. To minimise job creation time, wizard-driven job setup has been added to give operators more production flexibility and allowing last-minute changes at point of print, based on standard templates within ColorCert Pressroom. ColorCert 2.6 fits into any workflow with an interface to MIS systems. Users can also use PDF fields in supplied artwork to automatically populate job information as an alternative to MIS connectivity in some workflows, and multiple combinations of settings within a job is now possible. Version 2.6 has also extended Mac support to the scanning option for X-Rite eXact spectrophotometer.