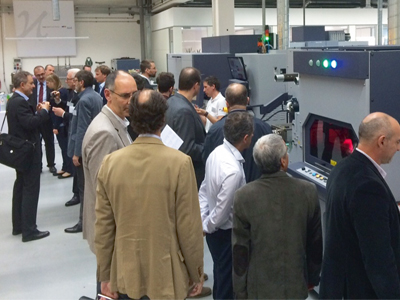

More than 150 participants from three continents participated in the Durst Digital Days held on 14-16 April in Brixen, Italy. The specialist in industrial inkjet applications presented the latest developments for the label and packaging industry during the three day event.

Helmuth Munter, segment manager of labels & package printing, led the varied programme of events, which included guest speakers from Rako Etiketten, TLF Graphics, SunJet and Spartanics. The main focus was on digital advancements with the Tau 330, new applications with low migration inks and workflow automation with laser finishing. ‘We are overwhelmed by the response and the large number of participants and see this as confirmation of the digital growth potential for label printing,’ said Mr Munter.

Market trends

In his presentation, Rick Hulme, global sales and product manager at SunJet, demonstrated the potential of low migration (LM) inks for UV printing. In partnership with Durst, the company has developed high-pigmented UV inks that comply with the various different migration rules of the European Union, Swiss Ordinance, US Food and Drug Administration (FDA), Japanese Food Sanitation Law and Chinese Packaging Regulation, as well as the directives of the European Printing Ink Association (EUPIA) and the American NAPIM. The complexity of LM inks also takes into account the various different forms of migration, ie penetration, contact, evaporation and condensation, as well as the different packaging materials used.

The Tau 330 is the first UV inkjet printing system for which LM inks have been approved. Certification was carried out officially according to ISO 17025 by SunJet and also by an independent laboratory. In addition, the integrated inert gas system reduces the typical odours of UV inkjet printing so that the requirements of the food and pharmaceutical industries regarding low odour printing processes are fulfilled.

Automation

The automation of production processes also contributes to the growth potential of UV printing. In his presentation, Mike Bacon, VP of sales & marketing at Spartanics, commented on successful cooperation with Durst in the development of an inline laser finishing system for the Tau 330. The complete system, the Tau 330 LFS, offers automatic end-to-end processing. The die-cut shape is created by the DFE software and sent to the laser finishing system with the printing data. Using a barcode, which is output with the printing order, the system selects the correct shape and automatically produces the die for the corresponding job.

As the first user of the Tau 330 LFS, US-based TLF Graphics shared its experiences. Bob McJury, VP of sales & marketing, was enthusiastic about the professional installation and initiation phase. He also presented a host of products made of coated and uncoated materials produced with the Tau 330 LFS to event participants.

By shifting from silkscreen printing to the Tau 330, TLF Graphics was able to reduce the amount of time required by up to 740 minutes (four color printing, print run of 2500 units). With regard to laser finishing, Mr McJury pointed out the different standard US sizes and the limitation in material strengths. Here as well, though, he was enthusiastic about Durst and Spartanics, which confronted the challenge and developed appropriate solutions.

As one of the largest label manufacturers in Europe, Rako Etiketten also shared its experiences. Roger Gehrke, manager of the digital printing division of the Rako Group, said that since installing the Tau 330 in October 2013, only one single printhead has failed, and only four maintenance tasks were required in 2014. The press boasts 95% uptime in 24-hour operation, and not a single customer complaint has been received. To Rako, the Tau 330 has been the perfect investment for minimising the conversion expenses from silkscreen printing. At the Hamburg location alone, these expenses amount to more than €2 milllion.

Durst also took the opportunity to present an update on what will be on show at Labelexpo Europe. As well as presenting a completely new Tau 330 system with all the new innovations, it is planning to introduce a more cost-effective version. The Tau 330 E will feature the same print quality, but a smaller set of features and options.