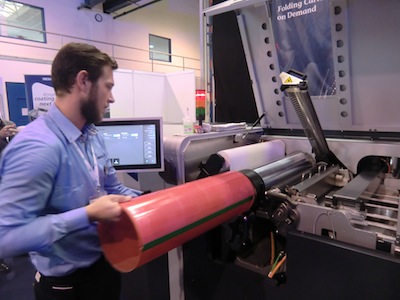

An operator demonstrates fast sleeve change on Tresu’s iCoat 30000 at the Kama open house

Kama, HP Indigo and suppliers, including Tresu presented the first end to end sheetfed workflow for digitally printed folding cartons at an open house event in Dresden. With every step in the process adapted for short run production, on-demand printing has arrived for this packaging segment, reports Adrian Tippetts.

Despite the availability of digital presses with both high productivity and offset-matching quality, folding carton production has until now remained almost exclusively an analogue process. However, the digital process for this packaging segment is becoming viable thanks to the recent arrival of coating and converting equipment, adapted to micro and short production runs.

Finishing partner

To show on-demand folding carton making, machine maker Kama staged a four-day open house with HP and partner suppliers at its Dresden headquarters, providing live demonstrations of a sheetfed ‘end to end’ workflow. With digital printing at its heart, fast set-up times, high level automation and fast throughput were evident at every step. Held between 11 and 14 November 2014, and attended by 450 printers from across Europe, USA, Brazil, Japan, Mexico and Australia, Kama Finishing (Innovation) Days also provided the occasion for the company, celebrating its 120th anniversary, to unveil its FlexoFold 52 folding and gluing machine, specially for this sector.

Located in one of the company’s production halls, an HP Indigo 30000 connected to a Tresu iCoat 30000 provided inline digital printing and coating. The substrate is fed seamlessly from the press into the inline coating system, which applies both spot and full cover aqueous and UV varnishes.

Yuval Golan, marketing product manager for the HP Indigo 30000, said, ‘We offer the option of a compatible inline coating system, in this case from Tresu, because we understood from the beginning, that almost all work in cartons needs at least one layer of protective coating, and perhaps extra layers of decorative coating. For the sake of efficiency, this process needs to be done inline.’

Job changeover within five minutes is possible thanks to a self-cleaning sleeve change process, and a dual automatic supply system. Thus, when switching between aqueous and UV jobs, it is only necessary to change the anilox roller. A stacker with buffer enables continuous, uninterrupted coating while pallets are exchanged. Tresu has launched a range of water-based and UV-curable overprinted varnishes (OPVs) specially formulated for the iCoat. Properties include excellent slip angle for easy feeding of the substrate, rub resistance to ensure brand integrity is maintained, and viscosity characteristics for optimised curing and drying at top speeds.

Mr Golan said, ‘After a six-month partner selection process, we chose Tresu as our technology provider because of its knowledge and experience in coating, being an OEM for the leading offset manufacturers and for having its own brand systems.’

World debut

On the other side of the hall, two standalone machines from Kama were converting the printed sheets into cartons ready for filling. The Kama DC 76 die-cutting unit with automatic registration camera and tool-less stripping and blanking unit, and – making its worldwide debut – the FlexFold 52, for folding and gluing with automated set up and pre-setting.

A distinctive feature of the FlexFold 52 is the newly developed APA-System (automated plough-length adjustment), enabling fast, precise calculation of the belt locations and adjustment of the folding belts automatically not only in transverse but also in longitudinal direction. The shortened tool setting time means that job set up, which can take hours on conventional machinery, occurs in minutes. Furthermore, glue is applied from below the substrate by a high-precision glue gun, resulting in a significantly higher yield than paste-reel alternatives. Other benefits include a compact footprint and electronic job ticket (JDF) network integration.

Michael Wenke, Kama, said, ‘The FlexFold 52 provides converters with the competitive edge in flexibility and cost control at a time when folding carton run lengths are diminishing from their present level of 6000 units to about 1000, on average.’

Kama CEO, Marcus Tralau, commented, ‘This complete networked solution for short run folding carton production hits the pulse of the times. Short runs are not profitable on high volume machinery, but they are now evolving from an unpleasant irritation to a growth market. What is needed is a solution with an uncomplicated set-up and minimal changeover times, something that can handle many job changes in a short space of time and which still delivers top quality while running with significantly shorter production cycles.’

Giving visitors full appreciation of the versatility, quality, speed of turnaround and variable data capability, samples printed at the event included boxes for cereals, snacks and cosmetics. At the end of the event, every visitor received a gift box personalised with their photo on the package.

Personalised folding carton samples

Transformed market

At a seminar to open the event, packaging analyst Mike Ferrari, president of Ferrari Innovation Solutions, outlined the overall drivers for digital printing, and the scope of opportunities.

Job runs are shortening thanks to the growing number of SKUs – an average US supermarket sells up to 48,000 – driven by the move to single-serve portions and smaller space-saving packages. With more products competing for the same space, brand owners have to stand out. Today, though, in the age of online shopping, good companies look at how we have to engage beyond the shelf. Multi-media entertainment, the internet and social media in the last 15 years has transformed the way customers buy retail goods, necessitating new interactive marketing strategies and digital printing workflows.

Six billion mobile phones exist globally, and internet penetration is 32% and rising fast. The consumer is creating content, seeking things that specifically speak to them. The customer’s first interaction with the brand is no longer likely to be at the point of purchase. The consumer learns of the brand first on an electronic device, perhaps through a review, recommendation or news item. Customers already have an opinion about the brand before they enter the store. Leading brands must ensure a positive experience at four stages: online, via shelf appeal, when the product is opened and consumed and disposed of.

The flexibility to customise the brand is key to success, and digital printing, with its ability to economically deliver shorter print runs, makes that possible. Mr Ferrari cited inspiring examples from Procter & Gamble which has been able to tailor its Tide detergent brand to the growing number of single male households through regional National Football League promotions. Clothing retailer Abercrombie & Fitch switched from an analogue to a digital print supply of folding cartons, and thus is able to buy its packaging eight times a year instead of bi-annual bulk buying.

Connection

Personalised products and campaigns that connect the virtual with the tangible world create bigger margins and strengthen brand loyalty. A leading tissue brand can sell for $10 online, four times as much as the same non-personalised product in the store. Via a website, a major yoghurt producer offers yoghurt drinks with an uploaded photo of the consumer’s child on the sleeve. This encourages more hits and ‘likes’ on the brand’s Facebook page where customers spread the word about their experience.

‘What started from digital media 20 years ago was just the printing part. That spawned so many industries – we have digital pre-press, inspection, business management, finishing and fulfilment – we have a new supply chain – the other pieces are there and it is a new eco system, with much better speed and agility,’ said Mr Ferrari.

According to Ferrari, if you change the consumer experience through packaging, you are more likely to achieve high growth. Merely saving product costs, changes nothing other than the way ink is applied to paper. The growth of digital print is accelerating because brand owners are recognising the opportunities associated with the process. Since 2013 for instance, P&G has been dedicating 35% of its marketing budget to digital media.

As Mr Ferrari pointed out, campaign creativity in the digital era is crucial, ‘Everyone can buy these machines – that in itself is not a differentiator. The USP for you versus another printer is the imagination and the purpose you will give that equipment. It is about how you put the pieces together. No one can copy your marketing plan. And so I suggest, become shopper and consumer focused, look at where the consumer is going because you need to follow them; reinvent your business – your business plan and marketing strategy; create value through speed and agility. It is a wonderful situation!’