(L-R) Stefan Heiniger, COO of the labels division at Gallus with Heidelberg CEO Gerold Linzbach and anchor investor Ferdinand Rüesch start up the new digital label printing system

More than 700 visitors from across the world attended the Gallus Innovation Days 2014, which were held for the first time at the company headquarters in St Gallen, Switzerland, in September.

The event ran from 23-25 September with the main focus on the world premiere of a new generation digital printing press for labels. Other innovations included additions to the Gallus machinery and service portfolio, the printing accessories programme, and the Screeny screen printing programme.

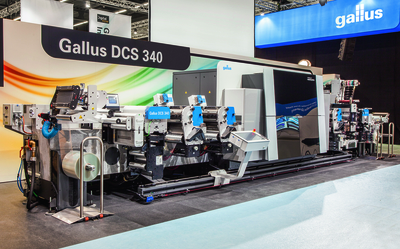

The new Gallus DCS 340 digital inline label printing system DCS (digital converting system) was unveiled under the ‘no more compromise’ banner to a global audience. With a native resolution of 1200 dpi, print speed of 50 m/min and maximum register accuracy, the new digital press promises to set high label printing standards in terms of productivity, flexibility and quality.

‘Due to continuing growth in short run label production and personalised, versioned labels, we are seeing investment on the market steadily shift towards printing presses that utilise digital printing. The growth potential for this printing method is considerable and we expect to see high growth rates over the next 10 years,’ said Stefan Heiniger, COO label business.

The press is the result of a project involving Heidelberg and its partner in inkjet technology, Fujifilm, and features a printing module with next generation inkjet printing heads. The design enables several heads to be joined together for a greater print width, without visible transitions.

The demonstrations of a DCS 340 prototype enabled the visitors to see the printing quality and fast job changes that can be achieved without any substrate waste. ‘We are not going to stop at the current printing speed of 50 m/min,’ revealed Stefan Heiniger, COO label business, ‘but want to improve even further upon what is already a very decent rate by the time the Gallus DCS 340 goes to market a year from now. Our aim is to create the most attractive digital printing system on the market.’

The press features a Heidelberg Prinect Digital Front End which is used to automate the pre-press workflow and ensure data is prepared efficiently, complete with comprehensive colour management. It also benefits from functions such as spot colour matching, the PDF Toolbox and Prepress Manager for even greater efficiency.

The new Gallus DCS 340 digital converting system prints at a resolution of 1200 dpi

At the Gallus expert forum, top specialists revealed the latest trends and technical developments in narrow web label printing. Mark Hanley, president of IT strategies, explained the importance and impact of digital printing in the label business, while Jason Oliver, digital printing manager at Heidelberger Druckmaschinen AG, predicted a fundamental change in the printing industry over the next few years as digital printing takes hold in print shop pressrooms.

Christof Naier, vice president sales and marketing at Gallus, remarked, ‘We are very happy with the way the event went, and the high number of visitors is evidence of the keen interest in our new digital inline label printing system as well as the need for it. The commitment that Gallus is investing in new digital printing technologies signifies another important step towards the full portfolio our customers require. This makes Gallus a truly all round supplier offering tried-and-tested conventional products alongside brand new digital printing methods – all under one roof.’