Labelexpo Americas offers live demonstrations of the latest machinery and materials

Marking its 25th anniversary with an enlarged focus on packaging print and the brand owner, Labelexpo Americas opens its doors between 9-11 September at the Donald E Stephens Convention Center.

Show organisers are promising visitors an enhanced experience at this year’s Labelexpo in Chicago in September. As the largest label and package printing tradeshow in the North and South American markets, the event will cover over 194,000 square foot of the exhibition halls. The growing list of includes more than 400 companies, including AB Graphic International, Avery Dennison, Delta, Epson, Flint Group, Fujifilm, HP, Karlville Development, MACtac, Mark Andy, Nilpeter, Nuova Gidue, Omet, RotoMetrics, Screen USA, Sun Chemical, UPM Raflatac and Xeikon.

A number of show features will offer added value. The Package Printing Workshop returns to show label printers how to diversify into folding cartons and flexible packaging, while the new Inkjet Trail (repeating the its success in Brussels last year) will put some of the available inkjet technologies under the spotlight and compare their results when producing identical label designs on the same label stocks. Participating press manufacturers are Domino, Durst, EFI and Epson. Other new initiatives include ‘Smart Mart’ where the latest smart and interactive label technologies will be displayed and the Craft Beverage Day for artisan beer, wine and spirit producers, while industry experts Mike Fairley and Mike Ferrari will be running packaging master classes for brand owners.

Tasha Ventimiglia, event director for Labelexpo Americas, said, ‘We have made some exciting changes since 2012 and this will help to increase both our exhibitor and visitor numbers. Our main goal will be to engage with existing and new visitors and offer them more easy and effective ways to improve and add value to their businesses. We have teamed up with a number of industry partners and are confident that the new feature areas will help take our label and package printing industry partners’ businesses to the next level.’

On show

AB Graphic (stand 3223) will unveil the new Digicon Series 3/RL label converting line equipped with unwind Corona treater controlled via main screen, flatbed foiling and semi-rotary (full rotary option) flexo application system. Rail mounted over-laminating for foils or laminates, flatbed screen printing unit, semi rotary die-cutting, plate mount and I-Score automated back scoring complete the specification. This will be running on the neighbouring HP stand with the new WS6800 where the Digicon 3000 can also be seen.

Also new for the USA market is the Digilase laser cutting system equipped with unwind, self wound/carrier rewind, rewind web advance, bar code job changes for I-Score and auto-slit for non-stop production capability.

Ashland Specialty Ingredients (stand 1329), a commercial unit of Ashland Inc, is featuring PureRad 53830 high gloss heat resistant OPV and PureRad 53860A high gloss UV resistant OPV. The print receptive coatings are clear, better fixate ink on a variety of substrates, and also protect it from aesthetic and functional damage during the intended life of the graphic.

In addition, Ashland is introducing a portfolio of laminating adhesives that further the safety of food in flexible packages while also advocating for a global risk-assessment approach. The new laminating adhesives will be marketed under the Safecure and Purelam trade names and have extremely low migration. The adhesives are solvent free and can be cured at room temperature, helping converters reduce overall costs and operate more efficiently.

Atlantic Zeiser (stand 6514) is introducing its new Digiline Booklet, an inkjet based roll to roll rewinder equipped with inkjet printing and camera for booklet label encoding and verification required for efficient and audit proof encoding, printing and verification of pharmaceutical booklet label used for clinical studies.

The machine encodes booklets up to 4 mm thick that cannot be processed with thermal transfer technology and allows high quality print on fully and partially transparent label stocks. Thanks to the digital print technology using UV-resistant inks, no more ribbons or print bars are required. This reduces working costs significantly.

The machine encodes booklets up to 4 mm thick that cannot be processed with thermal transfer technology and allows high quality print on fully and partially transparent label stocks. Thanks to the digital print technology using UV-resistant inks, no more ribbons or print bars are required. This reduces working costs significantly.

The machine encodes booklets up to 4 mm thick that cannot be processed with thermal transfer technology and allows high quality print on fully and partially transparent label stocks. Thanks to the digital print technology using UV-resistant inks, no more ribbons or print bars are required. This reduces working costs significantly.

AVT (stand 711) will introduce a new complete production management workflow system. PrintFlow IIis a set of three solutions that have been recently enhanced: PrintFlow Central serves as central storage for AVT’s PrintFlow database. It allows users to store, backup and monitor all aspects of print quality from one access point, regardless of site structure and location; PrintFlow Manager II is the successor of AVT’s quality data management system, which enables production managers remote access to all AVT PrintFlow databases installed on the company’s 100% inspection platforms; PrintFlow Online II is an inline data editing tool designed to optimise editing time and provide the operator with the most accurate online live quality status and production numbers, via live display or MIS communication.

AVT also will be debuting new process and quality control solutions at LabelExpo Americas, including the groundbreaking Helios II S,which inspects print applications that incorporate holographic foils and other special effects for both brand image and supply chain security.

AzTech Converting Systems (stand 1511) will be showing its Matrix modular digital finishing system.This is a flexible and expandable finishing platform capable of processing digital and flexo printed labels and media. The base system configuration is equipped with a 40 inch diameter unwind, LasX LaserSharp 400 Watt laser, waste winding, and 26 inch diameter finished roll rewind capability. The system is available in 10, 13, 18 and 20 inch web widths and operates at speeds of up to 500 ft/min.

Cerm (stand 5912) will be presenting the latest enhancements in its software. New features include improvements for handling sleeves and flexible packaging; interfaces to finishing equipment from AVT and ABG; extended LILO (lead-in lead out) management when ganging in Cerm; extending Web4Labels to end-customers and to sales people on the road (allowing quotes for renewal, quick quotes and RFQs) and an improved integration with Esko WebCenter.

Colordyne (stand 6455) will unveil the CDT 3600 series digital label printing press, a new addition to the memjet-powered production class family of digital print system solutions. Running at 225 ft/min (69 m/min), the press is a modular full-featured process colour digital label and tag production system housing an enhanced precision web handling system. The web handling system provides the latest in closed-loop tension control technology and is available with a full offering of inline finishing options and configurations.

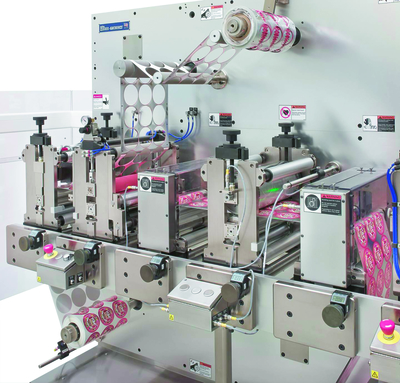

The Spectrum finishing solution from Delta Industrial

Delta Industrial Services (stand 3523) will feature the Delta Spectrum finishing system with the recently released embossing and hot foil stamping module, which enables die-cutting, embossing and/or hot foil stamping in one pass. Visitors will also see demos of its other finishing capabilities such as coating, semi-rotary cutting, slitting and laser die-cutting, including the Delta flexEDGE laser system which features a complete laser cutting system with on-board chilling, ventilation and controls. The module can be moved from one converting system to another and was designed to take the place of a die station. Compatible with a rotary converting or digital print finishing system, it can also be used as a standalone sheetfed system for process setup or R&D.

Domino (stand 6523) will showcase the N610i digital inkjet label press which prints with up to seven colours including opaque white, at a 600 x 600 dpi ‘native’ print resolution and operating speeds of up to 246 ft/min (75 m/min). The press uses vibrant UV curable inks designed for a range of industry standard self-adhesive label stocks including coated paper, polypropylene and polyethylene. Applications include industrial, security, health and safety, automotive, chemical, personal care, pharmaceutical, food, beverage and more. It features Domino’s proprietary i-Tech technology: ActiFlow is a continuous ink circulation system; CleanCap is an automated cleaning and capping system which cleans all the Kyocera jetting assemblies within one minute and protects them when not in operation; while StitchLink is an automated printhead calibration system which allows seamless print across the full print width.

Durst (stand 5901) will be introducing the Tau 330 with high definition print mode and inline laser finishing for digital labels and specialty packaging. The company will also be introducing its new low migration/low odour inks suitable for primary food packaging. Featuring a 14 inch web width with a 13 inch image area and printing at speeds up to 157 ft/min in seven colours, the Tau 330 with low migration inks expands the range of suitable applications and opens new markets for label and packaging print providers. The standard CMYK colour configuration can be upgraded with optional high opacity white and two additional process colours, violet and orange, to increase pantone-matching accuracy.

Durst will show the Tau 330 which is now available with low migration inks

EFI (stand 6423) will have theJetrion 4950LX LED digital label production system on its stand. This offers 720 x 720 dpi resolution, crisp, two-point text, increased Pantone matching, ink flexibility and substrate versatility. The modular design features inline finishing with dual head lasers and optional varnish/lamination station.

The focus will also be on the EFI Radius packaging and converting ERP software, and the recently released version 6 of Fiery XF, a flexible and scalable precision RIP and colour management workflow for proofing, package prototyping and fine art printing.

Epson (stand 5813) will be unveiling its next generation ColorWorks bench top label printer, which features a robust design geared towards higher volume industrial applications. As the first in the range, the system comes equipped with PrecisionCore print chip technology and is focused on merging enhanced image quality, ink durability, colour accuracy and print speed with reliability and efficiency.

Erhardt+Leimer (stand 329) will be showcasing its new Nyscan Web:Inspector, which has anew interface completely redesigned with the user in mind. Features include touch screen compatibility, sizable windows and flexible screen resolution.

Esko’s stand (5202) will have its many pre-press hardware and software solutions forcreating high quality packaging quickly and easily on display. This includes the recently released Suite 14, which enables better connections throughout the supply chain, improves workflows, achieves higher consistency and quality, and helps operators to work smarter with templates and intuitive operator tools.

FFEI (stand 5621) will demonstrate new enhancements to its hybrid digital UV inkjet press, Graphium. These include a new over white capability set to further extend the different applications and improve clarity of printed text, and support of substrates of 40-600 microns allowing the thinnest liners to heavy duty vinyl to be used.

Grafisk Maskinfabrik (GM) (stand 6125) will present its’Converting made easy’ concept showing several modular digital conventional finishing lines. These include the FB330 hot stamp / embossing one step module, which features a fast, compact optional rotating foil tower, and the DC330MINI compact finisher. There will also be two laser cutting lines, one mounted on the standard DC330 and a new entry-level special compact version of the L330 laser die-cutter, as well as a new fast exchange flexo station.

Grafotronic (stand 3118) will show the new entry level compact digital finishing machine. This includes a flexo unit, semi rotary/fully rotary die-cutting, laminating with cold foil option, slitting and rewinding. The CF-Series can be upgraded to a fully equipped converting line in the future. Other news at the show is the new updated HI-Series (horizontal inspection) with a Grafotronic designed web path integrated inside the machine, which is equipped with a 100% inspection system and capable of speeds up to 985 ft/min. Also being shown is the new Fully Automatic Core Cutter designed for label printers.

Graphtec Corporation (stand 3608) will be showing its new Labelrobo LCX1000 digital label system, which consists of the Labelrobo DLP1000 high speed and high durability electrophotography digital label printer and the Labelrobo DLC1000 digital label finisher with laminating, die-cutting, waste matrix removal, slitting and re‐winding.

HP Indigo (stands 3226 and 3429) will be the show’s largest exhibitorcovering 8,500 square foot – one of the biggest ever exhibition stand sizes in the show’s long history. It will showcase its portfolio of end-to-end solutions for label, folding carton and flexible packaging converting solutions. It will be putting the new WS6800 on display. The roll-fed digital press offers label and packaging converters faster turnaround times through automated colour management, a wider frame of 320 mm and new ink capabilities for expanded applications, including ElectroInk silver. With a new inline spectrophotometer using closed-loop control, it promises to match up to 75% of Pantone colours and eliminate the need for manual colour calibrations and adjustments.

Innovia Films (stand 1429) will be launching several new developmentsincluding a recently developed topcoat, UltraFoil, providing improved cold foil and fine tone capability for outstanding graphics, available in clear and white variants. Solid white films for the tyre label market will also be showcased alongside the company’s low distortion IML film, and inherently printable, squeezable films, Rayoface CZ Plus and WZ Plus.

The new MK2 ink controller

Industrial Inkjet (IIJ) (stand 3710) will be showing the new MK2 ink controller system for the first time. The product development launch has been a direct response to customers’ demands for fully automated turnkey systems to cope with larger industrial printers, and the system has already been piloted at some customer sites. As well as standard inks, the new design is also suitable for low migration inks, white inks, varnishes, primers, metallics, ceramic, conductive and security inks. This opens up new applications such as packaging, glass, flooring or direct-product-decoration.

iSys Label (stand 6413) will be showcasing the Edge 850, a roll to roll solution for printing full color BS5609 compliant labels as it has recently received the ‘BS5609 Section 3 Certification’. The die-cut labels deliver excellent resistance to water, chemicals, fading and smudges. With print speeds of 4.33 m/min and 9.14 m/min, the Eege 850 eliminates the need for ordering pre-printed labels, reduces inventories and allows customisation of each label with variable information in a single pass.

Mark Andy (stand 319) will be debuting its digital series, which has been designed to run high-quality jobs at full production speeds of 250 ft/min (76 m/min). Highly configurable, the press platform features high resolution six colour UV inkjet printing (CMYKOV + W) with top-coating and fully integrated in-line modules including flexo printing, various converting options, cold foil, screen and more.

Mark Andy’s new Digital Series will be running

MCS (stand 6546) will be showcasing the Eagle UV inkjet system, which is designed for flexo and web printers. System features include 4½” or 8½” printhead (heads can be combined for a total width up to 25″), 600 DPI, up to 333 ft/min, 2550 nozzles per printhead and adjustable drop sizes: 6, 7, 11 and 14 pl as well as oversized drop capability. It takes less than five minutes to set up and offers the choice of choice of UV-curable or water-based inks, including spot colour.

Newfoil Machines (stand 1829) has awide range of flatbed stamping, embossing, die-cutting and converting machines. The range of standard machines covers four web widths 170, 250, 305 and 330 mm, with single or multiple stations. Optional equipment includes inkjet/laser digital printing, holograms, RFID, screen and flexo printing, lamination, sheeting and punching. At the show, it will introduce its new 330 mm web width, high speed 3534 machine.

Prototype & Production Systems, Inc (PPSI) (stand 5410) will be showing DICEweb, the second generation of DICE printers, an inkjet module that adds quality digital colour printing to any flexo press, turning it into a hybrid machine. It delivers labels with fixed or variable graphics, text, and barcodes at speeds of 165 ft/min (50 m/min) or more. With an automatic printhead cleaning station, recirculating ink supplies and steel nozzle plates, it is available in widths up to 20 inches (508 mm) or more by special order, with four to six colours.

Schobertechnologies (stand 1317) will focus on the RSM-DIGI.vs system designed to convert digitally printed film and foil such as OPP, PE, PS and PET, coated paper laminates and composite materials. In fully modular design, the machine has integrated most of the proven stacking technology developed by Schober over the years. The rotary die-cutting module has been fully redesigned to cover the maximum image format.

The standard configuration of the RSM-DIGI.vs includes an M-Stack delivery system. Available as option or for future upgrades are the S-Stack, an adjustable de-nesting station to handle several products across as well as with a high speed programmable robot automated stacking and counting system (‘Spider’) which combines extreme acceleration, velocity and precision at continuous web speed of up to 50 m/min.

SPGPrints (stand 530) will be demonstrating its expertise in rotary screen and digital UV inkjet printing for labels and packaging. Its DSI UV inkjet printer is a modular concept for short and medium run digital label printing. This works as a standalone printing press or a full converting system with inline semi-rotary finishing. It comes with four printheads as standard, with the option to add another six to enable options like digital white, digital primer and an extended colour gamut through the colours orange and violet. The print width ranges from 135 mm to the standard 330 mm to as wide as 530 mm.

Sun Chemical (stand 5413) will demonstrate its capability in the joint development of ink solutions for single pass inkjet in labels, packaging and pharmaceutical applications, together with OEM partners and in collaboration with all of the major printhead manufacturers. A complete range of solutions for the digital press aftermarket will be on display during the show and include ranges from OPV to adhesives.

Vetaphone (stand 5605) will havean iCorona generator and two VE1A corona treaters with ceramic electrodes (UL approved) on static display on its own stand, while its units can be seen in action on a number of partner stands, including AB Grpahics, Domino, ETI, Gidue, HP Indigo, Nilpeter, Omet, Screen, SPGPrints and Werosys.

Xeikon (stand 6135) will show its wide range of digital solutions for labels and packaging. Highlights will include demonstrations of pressure sensitive label and folding carton production solutions, as well as samples of IML and heat transfer applications. The company is also taking part in the Package Print workshop where experts will show how to produce folding cartons using digital technology.

‘Whether you are looking to make a foray into digital printing, or you’re already established and are looking to grow your digital business further, we’ve got insights and innovations to share that you won’t want to miss,’ said Todd Blumsack, Xeikon’s VP of sales and marketing – North America. ‘Over the past few years we’ve significantly grown our portfolio of digital solutions for labels and packaging, and we encourage converters and brand owners alike to come check out what’s new.’