Dutch label specialist Geostick has always been at the forefront of digital printing. To entirely exploit the flexibility and productivity of its label presses, it turned to Esko and CERM to implement a highly automated and integrated workflow for its pre-press and administration.

Dutch printer Geostick BV has implemented a highly automated and integrated workflow from Esko and CERM for its administration and pre-press, to make the most of its label presses. ‘With the automation now in place, we can do more work in less time. And we continue to improve our performance every day,’ said Cees Schouten, Geostick technical director.

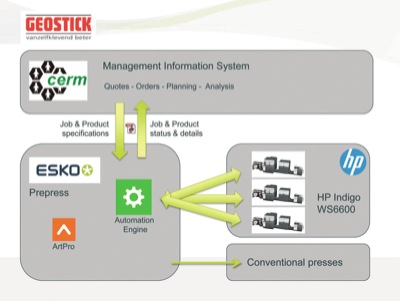

‘Switching to a new MIS system is not an easy process, as it is the heart of your entire operation. We are using Esko’s pre-press system to feed our digital and flexo presses. By adding Automation Engine on top and connecting it to the CERM MIS platform, we have brought our productivity and responsiveness to a new level.’

Automation and integration

Geostick is a family-owned company founded in 1924 by PJ Berveling, grandfather of the current owner. It is a leading full service provider of self-adhesive labels, active in the Benelux market. Complementing the design and production of labels, the company also offers customised labelling machines, label printers, foil, software as well as service and maintenance.

While implementing CERM’s MIS solution in its sales and order department, the company’s pre-press department started using Esko’s Automation Engine at the same time. Mr Schouten explained, ‘To start, we had to enter all available information on clients, orders and products into our systems. This took extra time and work, but as soon as the first repeat orders came in, we immediately benefited from those efforts. Our new configuration meant that these repeat jobs went directly to press – without human pre-press intervention, saving time and money for both us and our customers.’

Mr Schouten gives a great example of just how the company has benefited, ‘Some months ago, we got in a new, large account and had to input about 350 new items into our system, ready for production. With the old process, each item would have taken us at least 20 minutes in pre-press, but now, the job information and PDF file are automatically extracted from CERM, automatically preflighted and proofed, and sent to the digital press without any manual handling. We could never have done the job this fast and this accurately without the new integrated system in place.’

Business benefits

After working with Esko and CERM integrated automation for more than a year, Mr Schouten highlights the main benefits, ‘Jobs get to the pre-press department more quickly, where they are handled automatically. With less human intervention required, there are fewer mistakes. We now work very standardised, which gives us an up-to-the-minute overview of our workload and allows us to better schedule and combine jobs.’

The increase in productivity has been impressive, added Mr Schouten. ‘Before, most of our pre-press team members spent 20 to 30 hours extra per month to get all the work done. By the end of last year, we managed to eliminate overtime and one of our pre-press employees has taken a different position within the company, because we can handle the pre-press workload with fewer people yet still have capacity to take in more work.’

Mr Schouten is also very positive about the Esko support he received. Implementing an integration to Automation Engine includes having an Esko solution architect on site for five days, a specialised system integrator who analyses the existing situation, configures the new automated workflow and trains staff. Mr Schouten said, ‘After some time of putting the system to work, we invited him back to help us furthe optimise it. And even though we can do small changes ourselves, it was extremely valuable spending another few days together improving the system even further.’