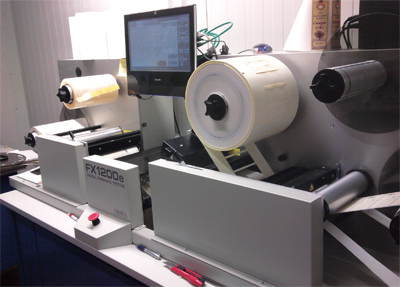

Primera’s FX1200e Digital Label Finishing System

Frantoi Cutrera is set in the heart of the Hyblaean Mountains, in south eastern Sicily. For generations, this family run business has been cultivating olive oil with love and dedication. In July 2011, it purchased a CX1200e Color Label Press and an FX1200e Digital Label Finishing System.

A family business, Frantoi Cutrera is located in the territory of Chiaramonte Gulfi, in the Hyblaean Mountains, in Sicily. In 1979, Mr Cutrera founded the mill that since 2000 has been managed by Salvatore Cutrera along with his sisters Maria and Giuseppina.

The oil producing company has been internationally known for many years for its high production quality and has won many of the most prestigious competitions including a gold medal in Los Angeles in 2005, a first place ‘Golden Lion’ at the 2004 Masters, a first place at ‘Festambiente’ 2004 Grosseto, and three olives in the Slow Food Guide 2003-2005.

Label problems

Due to the popularity of the oil produced by Frantoi Cutrera, a production volume of about one million bottles per year has been reached, which is almost entirely directed to the foreign market. Before implementing the new Primera system, the production of all labels was entirely handled by an outside supplier, which today is still used for very large label quantities.

This generated higher inventory costs and an enormous waste of unused labels, because many of these labels were either in excess, obsolete or incorrect. Moreover, the long lead times caused delays in shipping of products to customers. Waiting for labels also meant always working in a ‘state of emergency’ without opportunity to change or react quickly to any mistakes.

Full colour solution for small quantities

To solve this situation it was necessary to find a solution for printing full colour labels on rolls, allowing the company to be more flexible and independent in the production of smaller label quantities.

In July 2011, after careful evaluation, Frantoi Cutrera purchased the CX1200e Color Label Press and the FX1200e Digital Label Finisher – Primera’s professional label production solution – from Primetec Ltd, Primera Europe’s Italian distributor.

Salvatore Godano, production manager, said, ‘Today this solution is used mainly to print the back labels as those are produce more jagged. Our oils are exported to 34 different countries. Furthermore our customers frequently request customised labels.’

Applications and opportunities

With the CX1200e Color Laser Press, hundreds, or a few thousands, of labels can be printed on demand. In addition, sample prints for new products can be created, and above all, Cutrera can meet the demand for personalisation from all its clients.

‘We chose Primera’s CX1200e because it offers an unequaled print quality and with the FX1200e finishing system we can realise any label size and shape in a precise and fast way,’ said Mr Godano. ‘Primetec’s technician installed the machines and took care of the training. The training was held a couple of days putting us in the position to immediately use the machines. Once you become familiar with the system it is easy to use.’

He continued, ‘Currently we produce about 10,000 labels per month. The material that is used for our labels is matt, glossy or laid paper, white or beige, depending on the product type. We expect to increase the monthly production volume soon due to activities for third parties or because of our new product lines that are introduced to the market.’

Choice of investment and cost

When talking to managing director, Salvatore Cutrera, about the financial aspect, he commented, ‘The investment was made in view of accelerating the label availability and then consequently the whole product shipment and to reduce total cost of producing small label quantities.

This allowed us to better meet the demands of existing customers and certainly allowed us to win new ones.’ He continued revealing that, ‘In particular, we are introducing a new line of canned food for which we intend to use the best CX/FX combo system to produce all the new labels. On top of that the time needed until the amortisation of the system will be reduced, too.’

The printing cost of an individual label produced by a digital colour laser printer for label rolls might be not the most economical if you look only at the price of one single label, but the overall production of small quantities is as fast and as flexible as never imagined before, resulting in considerable time and cost savings. In the end the value of all accrued benefits is higher than the cost of the supported printing technology.