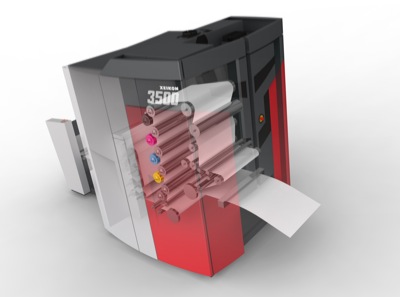

Xeikon 3500

As the sale of Xeikon to a Dutch private equity firm is announced, Sean Smyth looks at the latest developments from the company and its position in the market in 2013.

In January this year, Punch International announced it had been approached by an unnamed party to buy its shareholding. On 18 July, Xeikon announced that its major shareholder, Punch International had agreed to sell its 65.68% share interest to the Belgian division of Bencis Capital Partners, an independent Dutch private equity firm targeting medium-sized companies in the Benelux countries.

Another equity partner, Gimv will take a minority stake. The offer price values Xeikon at €169 million and the transaction should complete in September, when it would take the rest of the outstanding shares.

Interestingly, Bencis also took full ownership of StorkPrints in March this year, up from its 60% stakeholding, and it recently divested ANI Printing Inks and Biegelaar – Neroc, a print and pre-press group. So it knows the sector.

Future opportunities

Xeikon’s management are unable to comment on the takeover. Away from the ownership question, it is making very public statements about the future opportunities. The company has been steadily developing its product range and working on new developments to refine and improve its products. Labels and packaging now accounts for some 60% of new press sales, self-adhesive labels are some 82% of new installs, heat transfer labels 12% and folding cartons 6%.

It is the number two supplier in digital packaging and labels behind HP Indigo, claiming a 20% share of new installations globally, with higher share in Europe, Middle East and Africa. 30% of all new label and packaging presses are the wide web 3500 model (though the upgrade path for all machines allows users to increase the productivity of any installed machine).

The technology is developing. The Alpine fuser drum features a softer surface layer to handle heavier stocks. This will be demonstrated at Labelexpo in conjunction with an inline Bograma finishing unit for cartons. There is a new set of toners, ICE, to improve the range of label stocks that can be used by allowing fusing at temperatures some 10-15°C lower than the 90-120°C currently in use. This will open PE (polyethylene) stocks that cannot be printed on existing Xeikon machines. ICE will be released for new machines from this summer, while a field upgrade will be made available for installed equipment in 2014.

As part of the launch, Xeikon invites converters to upload their files that will be printed on a range of stocks including PE at www.seetheproof.com. This website lets converters to upload files and the printed results can be picked up at Labelexpo, where it will show an integrated label production system featuring a Xeikon 3300 with laser die-cutting from GM inline, controlled by a variable QR code. The system will be controlled by the Web2Label workflow that offers a customer facing website that allows jobs to be ordered and files uploaded into the job queue.

Toner technology

Away from labels, Xeikon is developing a new liquid toner technology, Trillium, which is being positioned as having inkjet productivity with toner quality. The first installations are set for early 2014, for document applications onto paper. The company will wait before launching a label/packaging version as the interaction with stocks is far more complex, but it is in the long term pipeline.

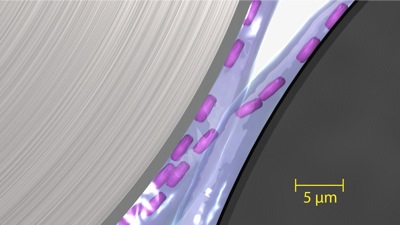

The mechanism is elegant. The print units comprise a liquid reservoir with anilox to a development roller that transfers toner onto the imaging drum. The image data is exposed using the same LED exposure bar that are used in the current Xeikon technology, this tranfers toner onto a transfer cylinder and then to the paper. This is a four-stage transfer processes, with a very highly controlled micro-gap that concentrates the toner particles at transfer while recycling the high viscosity toner oil. The toner particles are flat disks, each some 2.5 microns in diameter and 1 micron high. Each of the cylinders is charged, pulling the toner to the surface that delivers a thin film of toner to the paper, helping boost the final image quality. This design imparts control similar to analogue printing methods. The liquid toner film splitting results in only the charged toner being transferred as required, to deliver a smoother result in a much thinner layer than in powder toner systems. There is a partial fusing process after each tower, and a complete contact heat and pressure duplex fuser before the delivery.

Xeikon Trillium toner transfer from development drum detail

Xeikon Trillium toner transfer from development drum detail

It is good to see the investment sector supporting the print and packaging sector. Xeikon makes very good working equipment with a very supportive and growing user base, making the most of the wide web in labels and packaging. Hopefully the new ownership will provide the resources to develop the next generation of products.