Digital print on corrugated is a potential growth market for printers. With turnaround times of less than 48 hours, no minimum order and the ability to amend designs right up until final print, it offers the flexibility that is needed to win the race to get products on the shelves quickly without compromising on quality. By Neel Madsen.

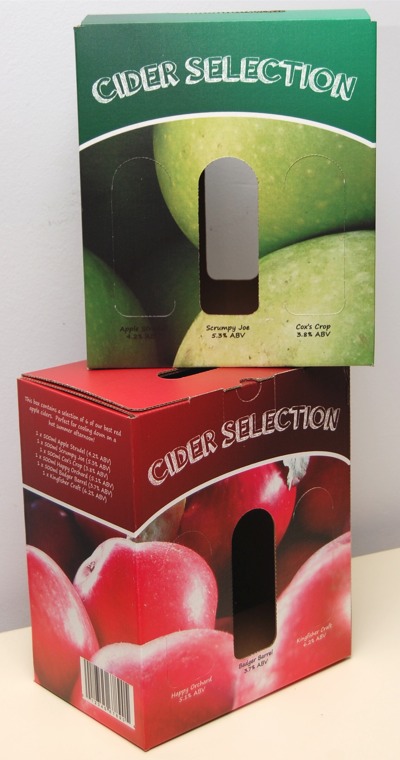

Gone are the days where corrugated packaging was used simply as a method for transporting the goods from A to B. In today’s fast moving consumer goods market, corrugated forms part of the shop display and high quality retail ready packaging (RRP) is now a key demand from brand owners.

If the corrugated packaging is going directly on the shelf then the print quality needs to be up to scratch. For long runs, the increased quality in flexographic printing (in the form of high quality post print or HQPP) satisfies, but with the ever changing designs and much shorter runs, digital is now making inroads.

The obvious advantage of printing corrugated digitally is the fast turnaround time, which means that the brand can have new designs on the shelf within days instead of weeks, enabling them to order smaller batches and react to trends in the market place instantly. The increased number of SKUs is another driver as is the trend for personalisation. And by printing only what is needed, there are furthermore major cost savings to be had in terms of storage and waste.

In terms of technology, there are a number of solutions on the market for printing corrugated digitally. These are mainly flatbed wide format printers aimed at the POS market, but also with short run packaging in mind, including folding cartons and corrugated. Suppliers include HP Scitex, EFI, Durst, Screen, Inca, Agfa and Xanté amongst others.

For finishing, there are Esko’s Kongsberg tables, Zund’s G3 digital cutter, Kase Make’s DYSS X7 digital die-cutting system and also Highcon’s Euclid digital cutting and creasing machine.

Read the full story in the April issue of Digital Labels & Packaging