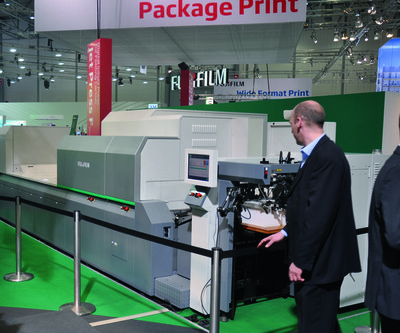

Fujifilm B2 sheetfed inkjet Jet Press F for cartons

Last year saw the launch of many new digital printing systems. While it is likely that not all will become commercial successes, it will not be through technical deficiencies. In 2013 there will be a wide choice, expect it to get wider.

Narrow web digital colour label presses are well established, with the Xeikon 3500 the widest high volume machine at 506 mm. Most are much narrower, with inkjet equipment from 108 mm up to 330 or 440 mm. The HP Indigo WS6600 machine is 319 mm, the new B2 HP Indigo presses has pushed the printing width up to 760 mm. The same printing engine is used in the 10000 press for commercial print that is now in operation and HP has produced two specialist versions for packaging.

Nosco, a full service packaging solutions provider based in Illinois, will be the first US customer for the special carton press, the 30000. It will use the new press to extend digital printing to larger order quantities and to produce customised cartons using variable data for serialisation, personalisation and brand protection.

Nosco is 106 years old and it serves 350 customers in regulated industries such as pharmaceutical, natural health and personal care. It has been using HP Indigo systems since installing its first press in 2004. President Russ Haraf commented, ‘We will soon be able to offer more digital printing capabilities to our customers, helping them improve cycle time and speed to market, lower inventory and obsolescence, and produce short to medium run folding cartons more cost effectively. Given the increased format size, speed and versatility of the HP Indigo 30000, we can economically produce cartons with a turnaround time of days instead of weeks.’

The first HP Indigo 30000 Digital Press is scheduled for launch at customers in late 2013. That will also be the launch date of the web fed 20000 aimed at flexible packaging with one of the pioneers Shere Print, part of Ultimate Packaging in Grimsby. General commercial availability is scheduled in 2014.

Up and running

There are other larger format digital sheetfed presses. Screen and Fujifilm have launched their B2 inkjet presses, and the first installations have taken place.

RCS in Retford, Nottinghamshire, took delivery of the first Screen Truepress SX this November and it is producing a range of versioned and short run products, including promotional packaging. According to managing director, Michael Todd: ‘Our target market is the high added value print run of one. In the future we would be delighted for every piece we produce to be different, a premium product commanding a premium price.’

The paper path on the press is straight which allows pre die cut and creased sheets to be run, greatly simplifying and speeding up the production of standard format short run cartons, for example for bottles of wine. The RCS website lists a range of products including boxes and packs that can be specified and ordered online and the company also has Scodix digital embossing to add more capability to products.

Fujifilm has its Jet Press 720, and has announced a specialist carton version, the Jet Press F that will handle heavier board and features new water based UV curing inks for durable instantly cured sheets ready for immediate processing. Both feature the Fujifilm Dimatix Samba wide array of piezo inkjet heads, with improvements in speed and quality in the pipeline.

Konica Minolta’s KM-1 machine, developed jointly with Komori also uses UV inkjet, while the Delphax elan, using water based inkjet with Memjet technology can also be aimed at cartons.

Liquid assets

Other digital sheetfed B2 presses include the UV inkjet MGI AlphaJet and the 8000 from Miyakoshi that uses liquid toner. Another liquid toner system, using lower viscosity material is the Océ InfiniStream system has an impressive specification and promises much. It is a web fed unit design system (developed with manroland web systems which handles the substrate transport), with seven colours across an imaging width of 711 mm at a linear speed of some 122 metres per minute. This equates to 14,400 x B2 sheets per hour (or 7200 x B1 sheets). The technology is an interesting application of liquid toner, with wet on wet transfer using electrostatics to ensure total toner transfer to the stock. The liquid toner comprises uniform colorant particles, between 1 and 2 microns that are dispersed in the liquid medium that gives a thin final ink film, similar to offset and the medium is evaporated and used to help power the heat set oven to dry the print.

Xeikon has been selling its 506 mm wide 3500 web press for many years, opening new opportunities in flexibles and cartons with its clear toner that can be cross-linked to provide a durable digital coating.

Océ claims its press will be priced the same as an equivalent offset press and will provide lower costs for up to 5000 sheets.

The new Landa digital nanography web machines will be useful for packaging when they come to market. The W5 is 560 mm in width while the W10 is 1020 mm – each has a top speed of 200 metres per minute. Both are simplex with up to eight colours (this will include white, but not using a nanographic pigment) and have labels and flexibles as a key target market. Landa claims these machines will be economic against analogue print up to 5000 to 7000 linear metres. The sheetfed S10FC is a B1 press aimed at folding cartons and sleeves, blister cards and microflute applications with a speed of 13,000 sheets per hour in simplex mode. The company claims a crossover point of around 6000 sheets, higher when ganging jobs or adding variable barcodes.

The detailed economics of this new technology has not been finalised, at least not in public. The suppliers know that to be attractive to converters there has to be a commercial incentive and the announcements by Landa and Océ on their presses being competitive on medium run work, and above. If they can deliver on these promises there will be many converters eager to snap up these new presses.

The activity in this market demonstrates the importance of packaging for equipment suppliers going forward. All forecasts predict continuing growth in packaging volume and value. Digital is opening up new short run and versioning/personalisation opportunities with the existing equipment. This newer generation of larger format digital equipment will allow more converters to transfer medium and long carton and flexible jobs to digital.