Amberley Labels knows how to get a quart into a pint pot (well, at least a third more sales into a label converter). Summer 2012 is busy and when DL&P visited the company was handling orders at 30% above capacity, helped by its digital operations.

Amberley Labels has been going for 31 years, the last 17 of them at the current location in Blandford, Dorset. The plant is BRC packaging certified and operates an ISO9001 system. The company does not produce pharmaceutical, concentrating on cosmetics, specialised food and beverage, general goods and some movement into ‘neutraceuticals’. It reports some £5 million in sales with a little over 50 staff. There are some 300 customers, many market leading brands, but not those on supermarket shelves. With the main accounts growing over recent years they now account for a significant proportion of overall turnover (managing director Trevor Smith commented that this had happened before. The last time Amberley made an acquisition, buying local competitor, Prolight Labels, that reduced the share for a while but it has grown again).

Into production

The production floor is organised into four manufacturing cells, flexo print, digital print, foiling and finishing. There are two Mark Andy flexo converting lines (a seven colour UV line and nine colour with water based inks). It produces some plates in-house, buying in high definition plates when needed. There are four semi-rotary foil and standard foilers still kept busy but it is digital that is growing strongly.

Amberley has long been at the forefront of digital label production in the UK. The company is a nine year veteran of digital production with HP Indigo technology – it bought a WS4000 press in 2003 and a second machine, a WS4050, two years later, then it installed a WS6000 in 2010, replacing the older WS4000 to boost capacity. It uses two off line ABG Digicon finishing systems, with foiling.

Last year it upgraded its MIS, installing a LabelTraxx system that has helped smooth the administration processes in handling well over 1000 jobs each month. Later this year it will be integrated with the Esko workflow system to get further benefits and reduce manual operations and time.

Trevor Smith is ambitious about his production capacity. ‘Customers care about what we offer, not how we do it,’ he said. ‘We want to be the world best digital printing company, because then the products we offer will be valued by customers.’ The company tries to focus on high value, complex jobs that are tricky to produce, where it can add value. Mr Smith calls it ‘systems differentiation through professionalism’. So, using digital print can broaden the range of services that can be provided. One example is in work produced for Marks & Spencer. ‘We had its design team down to look at a range of new products. We sell time on the Indigo press where we run versions of jobs that can be tweaked and run again to get approval. This helps M&S make final approval decisions much more quickly which is a great benefit for the customer.’

Driving digital

As the technology develops he see no good reason to go back to conventional printing, in fact the company has got rid of three flexo press lines in last three years since the installation of the WS6000. The HP Indigo technology is used to push quality, using the extended gamut six colour Indichrome set and white. The spectrophotometer control on the WS6000 is an important part of Amberley’s quality system to guarantee inter-batch colour consistency. There are controlled lightboxes throughout and all parts of manufacture are controlled carefully, from substrate selection and treatment, through printing and finishing (Estée Lauder expects all labels to be in exactly the same position, particularly for the clear carton seals). This means extreme care in final slitting and rewinding, with warnings on product reels to the applicator operators to avoid excessive tension, for example.

This can create issues when the company is busy, which it is this summer. It finds it difficult to subcontract work, even to companies that have HP Indigo technology. ‘Some suppliers do not use the same stocks we do, they do not all use six colours and the colour control is not always as we would like it,’ said Mr Smith. ‘It is not enough to have a technology installed, it is using it correctly that is important.’

Amberley set up its Special Products Division in 2002 and last year separated it out as a standalone business under Trevor Smith. It builds on the label converting skills (and the company prints many components) to develop products and solutions outside the more decorative label market. It has several development partners, looking to place accurately measured amounts of product on high speed moving webs, and cutting/finishing unusual substrates and constructions. Combining various materials in layers allow controlled release of products in an accurate and reliable delivery system. There are oxygen absorbers and scavengers, powder transfer and heat sealing.

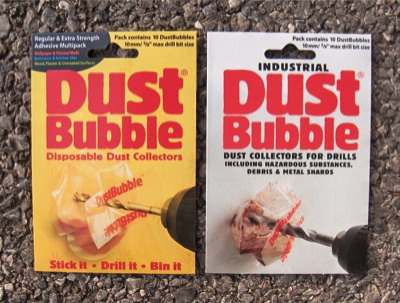

A very innovative development is the Dustbubble. This is a self-adhesive hands free dust encapsulation pocket with a patented multi-layer web construction, combined with innovative finishing to position a drillbit, and then catch the dust and masonry released in drilling. Developing these next generation products is broadening the range of products and services offered, but maintaining it as a separate business ensures it does not deflect Amberley from its core business.

There will be further developments in Blandford as Amberley decide how to take their successful business forward.