Promising super fast production of labels, at speeds up to 160 feet per minute, the new Colordyne CDT-1700 PC Pro digital label press and finishing system is now available through master distributor Delphax Technologies. The company will provide sales, service, support and consumables in Africa, Australia, Asia, South America and Europe.

This new colour system has been built on Memjet head technology, which not only allows for the excitingly fast speeds, but also high levels of quality at a sensible price.

In fact, the whole machine has been developed with cost effectiveness in mind. According to Colordyne, along with a low capital acquisition cost, there are no click charges, competitive consumables costs, low user intervention and easy maintenance.

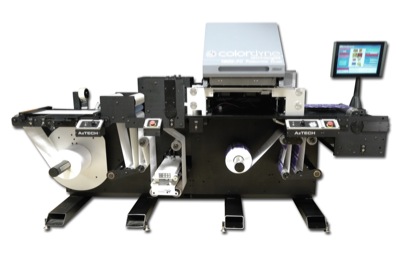

The relatively small footprint of the machine, ease of use through an intuitive touch screen system, and high levels of uptime means that the Colordyne combines productivity and efficiency with flexibility and convenience for print companies of all sizes.

The CDT-1600 is also able to handle a wide range of variable data applications allowing barcoding, serialisation and personalisation, along with own branding for shorter runs. The machine is ideal for printers and converters looking to produce fast turnaround labels and tags in small to medium runs.

Colour confident

The CDT-1600 employs five Memjet printheads, each containing 70,400 nozzles integrated into interchangeable ink delivery ‘blades’. These consistently eject some 3.5 billion drops of ink per second allowing high quality colour output at a resolution of 1600 x 1200 dpi.

The five print heads allow five colour output – CMYK or CMYK plus one spot colour, or up to five spot colours (spot colours by custom order), and the inks come in 10 litre containers for extended uptime and greater productivity.

The printer works well with both pre die cut and non die cut master rolls on water based inkjet compatible materials including coated and plain substrates.

Finshing faster

As well as speeding up your printing, the Colordyne CDT-1600 PC Pro comes with its own inline finishing system.

Made up of the printing unit – the CDT-1600 PC Sprint Production Class Printing System and the 1600 PC Sprint Plus Inline Finishing System (which has been engineered by AzTech Converting Systems) – the machine can be configured with a flexo printing/coating station, lamination station, die cut stations and slitting, with a choice of rotary shear, razor or pneumatic crush knife..

Features of this include a coating station with hot air dryer, GEW curing unit, Wilson Manufacturing Tint Roller and ceramic Anilox roller.

The lamination station offers a 20″ maximum diameter top side tower with 3″ diameter spindle.

Two dual framed rotary die cut stations come with 24″ maximum repeat with a choice of wither 10 or 13″ wide dies.

The CDT-1600 is ideal for all printers and converters looking for a fast and efficient colour digital alternative for label production.