At drupa Dainippon Screen will make several announcements that will prove to be significant in the development of digital packaging.

drupa will host the commercial launch of Screen’s JetSX, the PlateRiteFX range of flexo CTP and workflow, and a totally new narrow web inkjet press for labels.

The company has made no secret of its intention to become a significant player in the packaging sector with the launch of the flexo CTP system. There are several formats in the PlateRiteFX range and Screen’s colour expertise has the potential to push flexo quality further ahead. It wants to compete at the highest quality; it is where it made its reputation in the commercial print sector and it understands very high quality imaging well. It is putting together a good suite of workflow tools to push systems forward, with matching flexo and digital output high on the agenda.

Narrow web

There will be a new narrow web press at drupa that is currently under development. Technical details are sketchy – actually almost non-existent outside the development team – with no product name yet determined although TruePress 30/300 might fit the bill. The development is in Japan where label quality is very high so we expect the product will offer top quality. It is likely that Screen will utilise its workflow and colour management systems within the Equios workflow, with specific packaging tools it uses in the flexo systems, but with full variability.

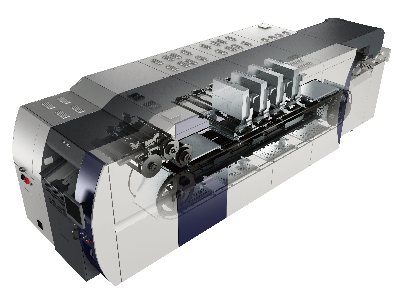

The sheetfed B2 Truepress JetSX press is now ready for commercial launch and the company has identified digital cartons as a key potential market. The machine is promoted as the first duplexing capability although this will not be too much use in cartons. The pricing of equipment and consumables has not been finalised publicly, but it is more than likely that the press will not be a direct competitor with offset. It shouldn’t be! The offset press suppliers are very good at improving the performance of their technologies. The digital press will do much more. For cartons there is a top range of 600 g/m2 or 600 micron, and full variable data capability. The format allows users to print much larger cartons digitally, opening up many new applications rather than small, lightweight material.

The press prints a maximum format of 528 x 740 mm onto coated and uncoated stocks, at a maximum of 1620 simplex sheets per hour in four colours, the equivalent of 108 pages per minute. The heads deliver 2 pl droplets, at an effective resolution of 1440 dpi in greyscale with Screen’s FM screening. However, users can reduce the resolution and run at higher speeds if the quality is sufficient. While there are no plans announced to upgrade performance experience suggests that the productivity will be increased in future. What will definitely happen is that as soon as these presses get into the hands of innovative printers will open up a range of new market activities.

Wim Koning acts as Screen’s Go to Market manager in Europe. He is working with several board suppliers to develop a range of pre-cut and creased designs, both micro perforation and die cut, that will allow printers to print low run lengths and avoid the requirement to source a die and then set up cutting and creasing in a separate stage.

Quality counts

Screen entering the digital packaging sector will be significant. The company enjoys a deserved reputation for very high quality, of both the print output and of the equipment it supplies. The inkjet quality from the initial samples of JetSX are very good with waterbased inks and there will be a coater offered for both UV or aqueous coatings – so quality will not be an issue. If it gets the costings right there will be a host of early adopters looking to develop a new revenue stream of personalised and very short run board packaging. Expect to see personalised and versioned wine boxes, cake containers, multipack beer bottle sleeves and various corporate and personal gifts. In the label space the company’s colour expertise will provide a boost for inkjet hat has steadily improved over the years.

Welcome aboard!