Hybrid Software held its annual ‘Huddle’ user conference at the Royal Air Force Museum Cosford on 3 April, where it gave flight to many new ideas for its modular pre-press software and offered guests demonstrations of some of the latest updates. By Michal Lodej.

In the old RAF hanger, surrounded by weaponry from the Cold War, Hybrid Software brought out some big guns of its own. There are currently 2500 of the company’s PDF editor Packz out in use today, and as of December last year, there 569 live licences of its graphics production workflow program Cloudflow.

Customers’ needs drive most of the developments, as Hybrid takes from its users what functions or changes they want the most. A customer survey at the end of the last Huddle led to one of the newer innovations being demonstrated at this one, a variable data printing (VDP) module.

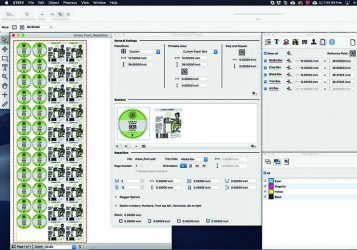

Another new announcement was Stepz, a standalone step and repeat program for digital label printers, which can be customised for different digital presses and finishing equipment. The first version is designed for HP Indigo users migrating to the new Production Pro DFE, with step and repeat templates that match the form factor of HP Indigo label and packaging presses, plus marks for common finishing devices. It also includes nested step and repeat for folding carton work and full VDP functionality for variable barcodes and text. It will be available to HP Indigo users for rental or purchase on the HP PrintOS Marketplace platform.

The spice of life

New for the latest version of the editor, Packz 5, is the VDP module, pre-flight reporting, waste numbering, file templates, sharpener and Packzimizer SSL for Cloudflow. Pascal Wybo, product manager, gave live demonstrations, showing visitors how to use the new functions.

One of the biggest announcements was a new VDP module. Current solutions for variable data printing modules are press vendor specific and not executed in pre-press. Mr Wybo explained, ‘If you have a mix of presses it causes problems. VDP is more than just barcodes and numbering, so a universal VDP is required. This solution will eliminate downtime from the printer waiting to prepare the job, leaving the presses idle. The ability was there in the previous version, but it was clumsy and it needs to be easy, so by building a wizard it can be done in just three steps: prepare, execute and output.’

Within the module, Patchworker can create unique variations of a design, line work or images and this is allocated with random placement with scale, mirror, rotate, move and quantity. This can be used in security applications as it can generate unique patterns.

The software helps to increase the speed of processing PDFs with variable data by changing the way the RIP reads the PDF. It creates a new layer structure for the RIP, as Mr Wybo explained, ‘We tell the RIP which element of the PDF is dynamic and needs to be interpreted for each variation, and which is static and so does not.’ Knowing which parts of the PDF are dynamic is key and keeps the software free from propriety programs, which has always been a huge benefit of the Hybrid Software.

While the solution can decrease rastering times considerably, the crux of the issue is the DFE reading the file: how often is it updated? Some can be left behind and slow down the whole process considerably. Some of the older DFEs will not experience any benefit from using the VDP module if they are out-of-date. However customers using the latest versions found that it made jobs up to 22 times faster.

Up in the clouds

Cloudflow is used in the main for file delivery and preflighting, quality checking and version comparison, and file management and asset search by Hybrid’s users. The program also offers pre-press automation, online approval, job management and output plate or delivery of prepared files. It has functions for accessing existing jobs, online ordering, tracking changes to synchronise files, production planning and control, and can create workflows and UIs to provide proof access and web-to-print capabilities. As a modular system users can adapt it to their needs. Giving access to critical information, a workflow engine can be build to automate file management to erase duplications.

‘Jobs’ is a new feature, which combines DTA files and folders, built around concept of production environment, where products are held in a database or reused. When a new job is created and the details are already in the system, it will autofill. ‘Viewing online’ is a popular function that allows users to create an approval portal or to start a new approval cycle.

Stepz can be customised for digital presses and finishing equipment

Future launches

Moments after demonstrating the latest features of Packz 5.0, Hybrid announced new features coming in v5.1 and v5.2, and the next generation v6.0, due to be released before drupa. In v5.1, which is in beta testing but has already received 80 user requests, users can limit the resolution of viewing to a maximum zoom, giving a level playing field with a set preset zoom level. There will be updates to barcodes including the addition of M&S barcodes, as well as an improved text tool for Asian and Arabic languages, and the ability to make measurements for the structure of the packages.

A smaller, but very welcome change, coming in v5.1 is the ability to copy and paste directly to/from Packz to Adobe Photoshop. The objects in the file become smart objects and complex backgrounds in a design are exported as images, but that can run better with fewer layers. So far less is known about the updates in v5.2, but Hybrid already knows it has to implement 30 user requests to keep up with partner announcements and updates. Other user base enhancements, such as text and background clashes, will be made as well as a tabular step and repeat function for seamless cutting bar width reduction pre-sets.

The biggest challenge has come from Silicon Valley with the Apple announcement of 6K displays. These beautifully crisp screens will require 64 times the amount of data per pixel than the current top range of displays, and so the company is working to speed up production inline with them.

Brothers in arms

The Huddle draws in input from users as well as other technology partners, who give their own presentations. Paul Bromley, business development manager at GMG, spoke about the usefulness of GMG OpenColor, and in particular spectral data. With this software, printers can test and experiment with colour choices, looking at the effects on different substrates, in orders of colour strengths, all online, before going to press. The system uses spectral data, which Mr Bromley said is far more accurate than L*a*b values.

Mark Hardaker from Creative Edge Software gave a demonstration of the company’s iC3D program, the real-time packaging software that designs 3D mock ups on the fly. It is able to recreate any packaging type in 3D vision. He said, ‘Printers, you can add it to your value chain as a service. It enables your customers to see the label in new light. It can give your customers new ideas and pre-press companies can get a good ROI from using it to trouble-shoot.’

Martin Bailey, Global Graphics CTO, spoke about PDF 2.0, which he described as a post-Adobe standard. He explained, ‘It has taken more than 10 years to get to this PDF, and it is no longer an Adobe product, but it is approved by ISO.’

With the new PDF standard comes new features, such as output intent, which means it will take into account the substrates being used. Other features include black point compensation, which can be switched on or off per job/page, or per graphical object for better reproduction of photographic images. Colour space inheritance means that when multiple jobs are ganged together, it can construct a file that honours the output intents for different jobs.

Mr Bailey concluded, ‘I’m sure you would all want print to be the driving force of PDF 2.0 adoption, but it won’t be. What will drive adoption is the new encryption, but this won’t work with old RIPs or DFEs. Another driver is the expanded accessibility support for printing elements, such as braille.’