A new e-commerce business has entered the market for short-run flexible packaging, utilising HP’s ecosystem to provide a new option for brands across the US looking to capitalise on the capabilities of digital printing.

The Packaging Lab has been established by Dan Niblo, CEO, and Jeff Searson, COO, as a turnkey business to facilitate quick reproduction of pouches, from origination and ordering, through to converting and delivery.

Located in Minneapolis, Minnesota, The Packaging Lab aims to turnaround orders in as little as 24 hours, up to a five-day maximum. It runs a 20000 digital press and two Karlville Pack Ready Laminators. One is configured to run matt laminate constructions, the other gloss. This allows the company to maximise throughput and efficiency by dedicating specific hardware to specific jobs. Slitting and pouch-making provide further tools to get packaging to market quickly.

Mr Niblo says, ‘We knew that anything you want printed, you can order online and receive quickly. Labels, photobooks and promotional items can all be produced in this way. Yet flexible packaging could not. So Jeff and I set about sourcing the tools to do so.’

Not having a printing background, the two entrepreneurs have been able to build The Packaging Lab from the ground up, unencumbered by preconceptions of how established flexible package printing workflows exist, and mitigating the resulting bottlenecks and issues that persist. This includes: minimum order quantities and run lengths; tooling costs; converting lead times often of many weeks; and the use of existing software to manage the flow of digital jobs coming in and being sent to press.

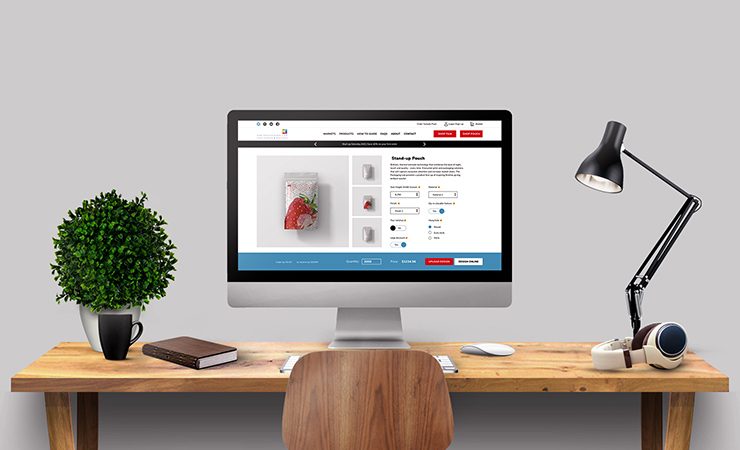

This last example has seen The Packaging Lab build its own software ecosystem, tasking Infigo to provide it with a web-to-pack system. Powered by Infigo’s Catfish web-to-print platform, visitors to thepkglab.com are able to select from 20 pre-defined packaging sizes – 12 stand-up pouches, eight flat pouches and films up to 76cm. Once the order is placed, Catfish submits it to HP PrintOS Site Flow via the PrintOS open API. Site Flow automatically batches like-jobs, applies step-and-repeat, adds finishing marks and submits the batched job to the HP Indigo 20000. Post-print, these are sent to the correct Pack Ready line for converting.

Regarding films, the company is planning to stock six different films: thin clear (BOPP), medium metallized (METPET), medium white and clear, and thick white and clear (EVOH barrier). It is also open to stocking films if the business warrants.

Customers are also able to request design assistance. Offered for a flat $250 fee, The Packaging Lab is able to task a designer to engage with the customer, provide designs based on their input, and deliver to them packaging that suits their needs. Another benefit is that designs are print- ready and optimised for the HP Indigo process.

‘Packaging is often made out to be more complex than it needs to be,’ notes Mr Niblo. ‘Our aim is to make ordering packaging as painless a process as possible, and perhaps even a little bit enjoyable.’

Big and small

For smaller, start-up brands, such issues in the supply of packaging could make or break a deal. Larger brands also stand to benefit, as Mr Niblo explains.

‘I can tell countless stories of when the supply chain has not been able to meet the needs of the customer, in terms of quantity, quality and cost. If you look in a store, the number of new products that are launched each year is gigantic. Some are new players but many are established products and brands targeting a new audience. This means there is big demand for short runs, for trials and market testing, from across the board. But you often can’t get them printed and shipped in time, no matter the size of your company.

‘Digital is the key to unlocking this potential, especially if you understand the value in digital. If you invest in a digital press, you need the systems and tools in place around it to maximise its value. If you don’t, you run the risk of ending up with a great press that opens up opportunities, but which you can’t take advantage of.’