State of the nations (part one)

Published: 29 August 2022 | No comments yet

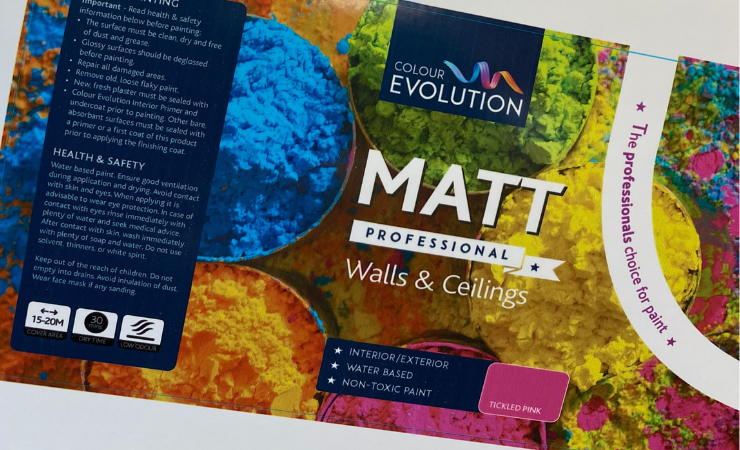

Digital is finding a home across a variety of end0use verticals, from food and beverages, to professional paints and wallcoverings

Digital has already seen widespread success across the Americas, but with a ‘new normal’ now in play and a wave of investments imminent, what will drive future successes?

As noted by Victor Gomez, director, industrial labels at Epson America, ‘Digital technology for labels and packaging came into its own following the economic crisis of 2008/2009. This spurred a big change in brand owner buying behaviour towards more frequent orders of shorter runs, expecting faster turnaround times. The trend towards mass customisation and personalisation had already started, but it was the financial crisis that brought digital label printing technology to the forefront to support those trends.

‘As we go into the second half of 2022, there’s a sense of déjà vu. The pandemic brought with it an enormous, sudden shift in consumer demand in 2020, even bigger than what we saw during the financial crisis.’

Giving his take on the current state of the market in the Americas, Kirk McLean, vice president and general manager at HP Inc, said, ‘As digital printing for labels and packaging becomes more mainstream, converters will be looking to invest in equipment and partnerships that will accelerate their growth, give them new capabilities, reduce their waste and streamline their production. Factors like software automation, data tool sets that can pinpoint inefficiencies in production, and print features like brand security will drive press purchases over the next 12-18 months.’

He continues, ‘Many PSPs across the region are also realising the sustainability benefits to digital printing and understanding how the switch to digital can ensure they’re not only meeting their own sustainability goals, but can also help customers meet their goals, by offering a more environmentally friendly service and end product – another key driver for the success of digital technology.’ He highlights Florida-based SunDance, which is using an HP Indigo 25K to meet the company’s sustainability goals by eliminating print media waste and plates, and using non-toxic inks and recycled print materials.

Commenting on the technology available in the market, Industrial Inkjet (IIJ) managing director John Corrall and his colleague Graham Vlcek, president of operations at IIJ USA, note that, ‘There is now arguably a surfeit of suppliers offering standalone digital presses. Some of these companies have started to offer “hybrid” machines combining digital, flexo and/or finishing capability. However, for many convertors there is still a reluctance to dispose of their existing trusty equipment to purchase duplicates of the capabilities already onsite, making an inkjet retrofit the best path.’

IIJ USA has installed a MonoPrint inkjet unit onto a Mark Andy 2200 flexo module to demonstrate the potential of inkjet retofits

IIJ USA recently created a demonstration system to help highlight these capabilities, with a late 1990s two-colour Mark Andy 2200 purchased and installed with an inkjet retrofit. Around half of retrofits by IIJ USA have been on Mark Andy presses, note Messrs Corrall and Vlcek, with the presses often around 20 years old but still in good working conditions.

‘When trying to sell any print system, there is a need to meet or exceed a print quality threshold that the customer will regard as normal for their business. The requirements do vary but there are always expectations about the sharpness of the printed image, the accuracy of colour reproduction, the range of colour reproduction, and the smoothness of the image. Although customers will often try to quote specific target values, in reality the decision almost always comes down to whether they like the print samples or not. Once the customer is persuaded that quality goals can be met, the next question is always about productivity.’

They continue, ‘At this point, if the customer was buying a complete standalone digital press, they would have been able to touch the supplier’s demo system, would probably be allowed to actually operate it, and will have seen for themselves how well it performs over a few hours or even days.

‘When buying a retrofit inkjet module, the situation isn’t quite the same. A demonstration system is likely to be fitted to a simple unwind-rewind system rather than an actual flexo press, and very often any print samples supplied will have been created on a laboratory machine or a purpose build web system. It then becomes difficult for the customer to judge whether the performance being shown can be replicated in their set-up.’

To show more of the market what’s possible with an inkjet retrofit, IIJ USA has also invested in a mobile demo station that it can be taken to trade shows. This involves a single module from a Mark Andy 2200 fitted with a MonoPrint inkjet engine. This is on display at Labelexpo Americas 2022.

For even more exploration of the market across the Americas, be sure to read ‘State of the nations (part two) here, and the July/August 2022 issue of Digital Labels & Packaging; register here to receive the magazine

The rest of this content is restricted - login or subscribe free to access

Thank you for visiting our website. To access this content in full you'll need to login. It's completely free to subscribe, and in less than a minute you can continue reading. If you've already subscribed, great - just login.

Click here to Subscribe today Login here