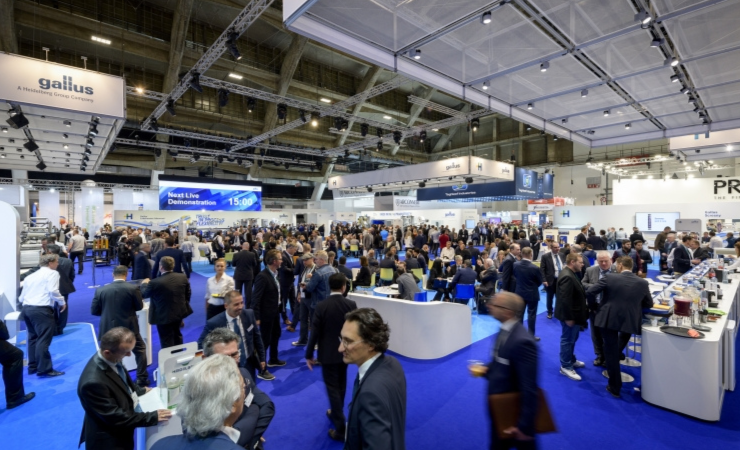

Labelexpo Europe returns later this year, following a four-year stretch between instalments of the flagship trade show for the label and package printing industry.

Last taking place in September 2019, much has changed since then in terms of both the technologies and the drivers shaping the future of narrow and mid web printing and converting. Whilst other Labelexpo shows have taken place around the world over the last 12 months – notably in America, in Thailand and in Mexico –, Europe remains the jewel in the Labelexpo Global Series crown. Attracting an international audience, the show is the largest in terms of exhibition space and exhibitors. It also has a long-standing reputation as a launchpad for new technologies, which, according to Jade Grace, Labelexpo Global Series portfolio director, can be expected again this year. ‘We will see an explosion of cutting-edge technology launched at the show, everything from pre-press to materials, and digital and conventional print and converting technology.’

Andy Thomas-Emans, strategic director at Labelexpo Global Series, continues, ‘We are already seeing key technology themes emerging; diversification across labels and flexible packaging technologies, digital embellishment, workflow and machine automation, real-time data collection over the Cloud and sustainability across multiple fronts. This will be a landmark show for the future direction of our industry.’

Virgilio Micale, sales director at Cartes, confirms, ‘Labelexpo Europe has always been characterised for the latest technology solutions launching and we firmly believe the next edition will be outstanding in this regard.’

In terms of digital technologies, there will undoubtedly be a large amount of things to see at the show. From the HP Indigo V12, Dantex PicoJet 1200s and Domino N710i for labels, to Xeikon’s CX500t Titon toner press and the Screen Truepress Pac 520P for packaging, big iron will no doubt make the headlines. Durst, Epson, Gallus, Konica Minolta and Mark Andy are amongst other press manufacturers to expect developments from – read the next issue for more. In addition, advances from the likes of Cartes, Cerm, Prati, Rosas, Smag and more will ensure developments from across the supply chain are presented.

These will have been developed as a result of the drive towards higher levels of automation, increased demand for embellishment of short runs and long runs of labels, according to Antony Cotton, technical sales manager at Focus Label Machinery. He adds, ‘There will be more crossover from labels to flexible packaging applications and wider adoption of traceability technology.’

Examples of systems that respond to these trends are d-Flex with inline flexo and converting facilities and Reflex digital finishing equipment, both of which are to be shown by Focus at Labelexpo Europe 2023.

Cartes is to demonstrate its newest technology for digital embellishment, such as Jet D-Screen, in combination with laser converting and process automation, ‘completing a perfect match with a roll-to-roll digital press concept,’ explains Mr Micale. ‘We will exhibit the most required configurations for embellishment and converting processes, combining all our units and showing how it can be tailored to achieve specific customer needs.’

Arrow Systems is to showcase a wide range of digital printing and finishing systems, such as ArrowJet Lite and EZCut 330R. These respond to some of the major trends Arrow Systems has identified in recent times, as Shaan Patel, who is responsible for business development at the company, details. ‘Customers are demanding shorter runs and manufacturers are looking for ways to tap into this space without having to make a large investment. We expect this trend to continue through this year and over the course of the next 5-10 years as more and more traditional label and packaging printers make the shift to digital.’

Durst similarly expects increasing demand for digital printing technologies coupled with a continued shift towards sustainable options. This all equates to the ‘need for more sustainable production’, according to the company. Durst’s Tau RSCi and Tau RSC E label printing systems will be shown as ones for high-quality, cost-effective printing at high speeds, with minimal setup times and waste. Software developments to streamline workflows and improve overall efficiency will also be shown by the inkjet digital press manufacturer, as will Hawk Eye, which deploys camera vision systems with the goal of automating print quality.

More generally, Durst anticipates a greater focus on automation and efficiency as printing companies seek to streamline their operations and reduce costs. This is a view shared by Mr Micale, who says, ‘New trends have begun to consolidate in the market and challenges are now more complex. Thereby, we expect to see innovated solutions to allow customers to reduce time and material waste, along with optimising production costs and increase their profit margin.’

In a similar vein, A B Graphic (ABG) expects automation to be this year’s hot topic. Connect is ABG’s brand-new automation portfolio offering options from basic data entry and capture, to complete, operator free operation. This will be shown in action on a Digicon Series 3, in partnership with Cerm. New-look Vectra turret rewinders, new Digicon and SRI modules and an updated DigiLase with decal function are to be presented. ABG is also to focus on high-speed production and minimising downtime, with systems developed in direct response to the introduction of presses such as the 120m/min HP Indigo V12. This will include non-stop winders designed specifically for the LEPx press.

For Patrick Citroen, managing director at Amica Systems Europe, ‘Investment is a continuous process.’

He goes on, ‘We invest in product development, special unique application software and in new systems for specific market places, for which we can offer unique solutions.’

This is to be realised at Labelexpo Europe 2023 through a series of full-colour label presses. Amica Systems launched the Gemini 330-4C UV label press in early 2023 together with the LPS330 label press. These are to be followed by a family of six-colour narrow web UV label presses.

Specifically, Gemini 330-4C UV is a 600 x 1200dpi standalone press with a roll-to-roll drive train and arc concept to ensure required web tension. The is a scalable option, starting from a CMYK UV inkjet digital label press with a 216mm print width, to a 324mm-wide option by the addition of printheads across the print width. Fully automatic purge, wipe and cap functionality is included as standard to ensure uptime, with inter-colour pinning lamps creating a ‘stable and crisp’ print quality. The Gemini 330-4CIS is then a module for integration into existing systems. Also offering CMYK UV inkjet digital printing, this system is fully equipped with its own base module including support rollers to simplify integration. G330-4CIS similarly comes with automatic purge, wipe and cap functionality.

LPS330 is offered as a UV LED inkjet press tailored for short and medium run jobs. This has a 320mm print width and a resolution of 720 x 1200dpi. Printing is done with CYMK ink channels, plus double white and double digital varnish capability. Specifically, printing of white is supported by under- and over-printing options to deliver solid and opaque white ink layers on transparent films and metallic substrates. With a highly engineered and compact design, LPS330 combines the technology of scanning printing with that of single-pass processes. This makes it suitable for printing labels, variable data and industrial decorations, and is noted as being especially suited for the growth of in-house label printing and/or for printing companies who receive requests for short runs.

Further to these, the Scorpio family of six-colour narrow web UV label presses will provide an entry point into the market for digitally printed labels. First up is to be the 150mm-wide Scorpio150, which is to be followed by the Scorpio54, Scorpio108 and Scorpio75. Each of these offer CMYK+OG, are fully equipped with an automatic cleaning system, and use LED pinning lamps makes it possible to print on a wide variety of materials, such as PP, BOPP, PVC, glossy paper and standard paper.

All of Amica Systems’ new full-colour digital label press are driven by the company’s proprietary NuviPRINT software. This is professional RIP software designed and developed for industrial inkjet printing applications, offering a claimed, ‘fast RIP speed, reliable and efficient job printing production, and streamlined workflow.’ Smooth gradients, vivid images and sharp small size text can be achieved with this RIP technology. Further, ICC colour management workflow ensures ‘vivid and brilliant colours’.

Commenting on the potential for these digital printing options, Mr Citroen says, ‘Underneath, a large, untouched market is emerging for label presses in the mid-segment and low market segment, offering great potential and new opportunities. We certainly want to set the standards into this market.’