With the industry progressively gearing towards full automation, robotics are set to facilitate this transition. Taylor Sinclair explores how it has and will affect the industry.

With a constant need to innovate – not just in the print industry – technology has become a pivotal and integral part of everyday life. Companies have been integrating robots into processes for some time, an area of innovation which has been heralded as the ‘next big step’ in the industry.

Agfa’s head of packaging Matt Brooks, commented, ‘This [robotics] has been good for the industry as demand for higher volume throughout printers occurred. The need for faster, automatic sheet handling became greater. Robots offered the most cost effective, agile solution to facilitate the demands and offer future benefits such as minimising touch points and automating the end-to-end process. In some cases, the industry is moving towards ‘lights out’ production and robots are key to that success.’

A shift towards ‘lights out production’ is becoming increasingly popular, boasting a variety of benefits: increased productivity, more output and reduced downtime. A concept only able come to fruition with robots.

Jordi Giralt, Kama’s chief business officer said Kama has only recently incorporated robotics into its printing process but has made significant strides forward in a short period.

Kama’s concept for a fully automated workflow in close cooperation with Yaskawa, Japanese manufacturer of industrial robots, will look ‘to solve the bottleneck in print finishing with customised robotics and make finishing as flexible as printing has become’, said Mr Giralt,

The company’s robotised transport of the die-cut blanks including the automatic removal from the die-cutter and the loading of the fully automatic FlexFold 52i folder gluer by robots, makes Kama, as of today, the only company in the world that can move from the printing press to the finish box without any operators, explained Mr Giralt. In a further step, the robot system also takes over the change of tooling at the die-cutting machine. ‘All we do is just push a button and everything gets done by robots,’ he remarked.

Another company expanding its robotics integration is printing equipment manufacturer Bobst following the integration of Dücker Robotics into its structure as of early March 2024. A deal for Bobst to take a 70% stake in Dücker Robotics was concluded at the end of April last year. At that time, Bobst CEO Jean-Pascal Bobst said, ‘In an era where converters are facing higher demands than ever due to the booming global demand, specifically in the e-commerce market, while simultaneously facing challenges in shortages of manpower, automation has never been more important for our clients.’

Bobst added, ‘By integrating robotic solutions into our wide portfolio, [we] can help boost end-to-end efficiency for corrugated packaging production.’

Key benefits

The key benefit to robotics, which is a hidden one, is that they must be instructed on what to do, explained Mr Giralt.

He told Digital Labels & Packaging (DLP): ‘By having a robot, you need to give it instructions on what to do. The robot will not think but itself. By instructing you are already creating a level of standardisation of a process, removing the freedom which operators will have. This reduces the risks of errors, removing the repetitive part of the process. Robots are for sure the next big step in the printing industry.’

With a reduced risk of errors, efficiency and productivity can be maximised. Mr Brooks said by using robots, Agfa can utilise its machine to a higher degree, allowing the printer to do what it does best and print. Robotics can take over the job change over and the full material handling, which is a massive time benefit, subsequently increasing productivity and efficiency, he commented.

In agreement, Mr Giralt also stated, ‘To become more productive and efficient is difficult because all the machines are state-of-the-art, but by using robots we are moving into a new field of excellence.’

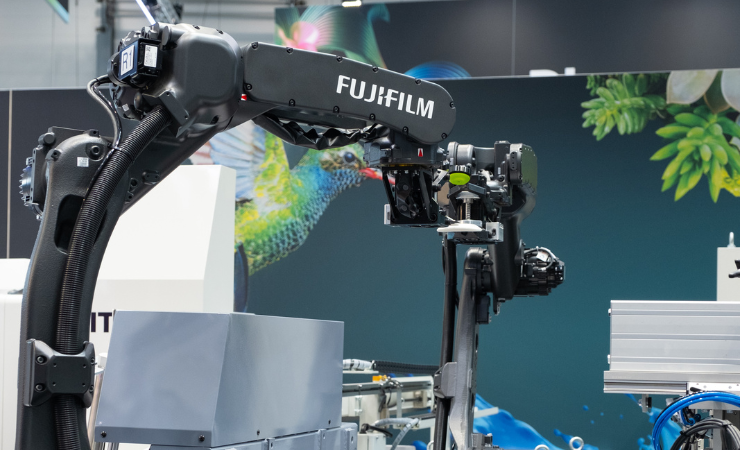

Stuart Blackham, solutions manager at Fujifilm UK, explained that robots also play a significant role in eliminating manual labour – reducing the risk of injury – shifting human involvement to system monitoring. This all aligns with the company’s aspiration of ‘Giving the World More Smiles’, he said.

Mr Blackham added that robotic systems also offer the potential for continuous 24/7 operation with minimal downtime – linking back to the ‘lights out production’ concept. ‘This is particularly advantageous given the industry’s trend towards shorter runs and digital print, which require more steps that can be automated,’ he commented.

Looking ahead

As outlined prior, robotics has come a long way in cementing itself as a key area within the industry. But what does the future of robotics look like?

Mr Brooks highlights its importance in solving industry issues. He told DLP: ‘For the future it is more towards automation and connectivity. Integration of robots into finishing lines. Utilising robots to move jobs around a factory and onto the next process step. The industry generally wants to minimise human touch points and manual intervention. Robotics are really the only way to do that with software and electronics controls. The industry is struggling from a labour standpoint. Robotics are the obvious answer to help solve this challenge!’

He added, ‘We see more and more OEMs investing and developing robotic solutions and drupa was a perfect example of how our industry is forward thinking about connectivity and automating as much of the process as possible.’

As the industry continues to develop and innovate, robots will not be going anywhere, in fact, they will only continue asserting their presence throughout the upcoming years. The robot revolution is well and truly thriving!