Embossing adds a tactile and visual dimension, debossing offers an understated and refined look, and hot and cold foiling adds an eye-catching metallic sheen. Labels and packaging are often the better for them.

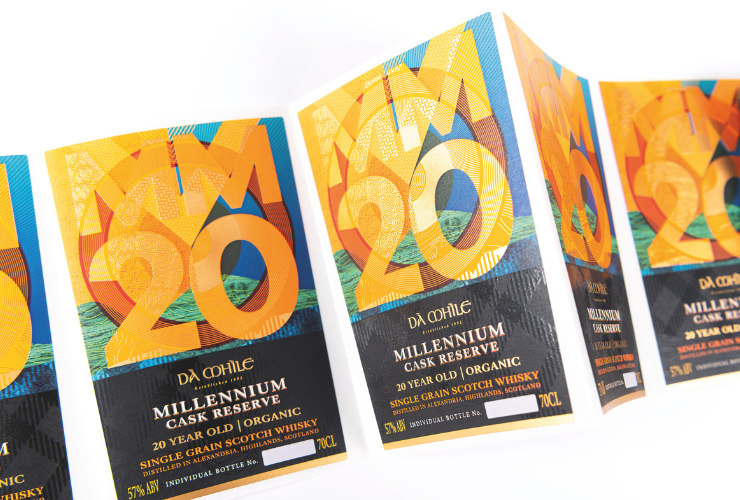

When print embellishment is done well, the result can be the creation of something truly beautiful. The Digital Labels & Packaging Awards this year saw just such a coming together of excellence in printing and finishing, with the Supreme Award being taken by The Label Makers for an entry that was described by the judges as ‘poetry in motion’, a ‘beautifully crafted label’, and a ‘perfect marriage of print, foil, emboss, harmoniously integrated to deliver a beautiful and cohesive label’.

The multiple layers and levels of the piece for Dà Mhìle Millennium Cask Reserve Whisky, printed on a Xeikon press and finished on an AB Graphic Digicon Big Foot, brought ‘delight and surprise, whilst still delivering a clear and dynamic brand identity’, the judges said.

Poetry in motion: The Label Makers’ Supreme Award-winning entry at

the Digital Labels & Packaging Awards this year

Print embellishment is of course an age-old field, and many traditional techniques are still carried out by label and packaging printers and specialist finishers. Alongside these techniques, digital embellishment is on the rise. Cutting-edge digital technology enables intricate textures, metallic finishes, and 3D effects to be added to packaging and labels with precision and speed.

Digital embellishments can emulate traditional techniques at a fraction of the cost, and without minimum order requirements, says Kevin O’Donnell, head of marketing, Graphic Communications & Production Systems UK, Ireland & The Nordics, for Xerox.

‘The digital approach offers speed, flexibility, and economy over traditional methods, allowing print service providers to offer enhanced options to consumers without significantly increasing costs or production time. Combining speciality media with digital embellishments and personalisation creates a winning piece. This approach is particularly well-suited for short-run digital packaging – a rapidly growing market segment.’

Material matters

Whichever embellishment is intended to be used, one of the first considerations is the suitability of the proposed substrate. Jamie Godson, technical manager at Baker Labels, comments, ‘Embossing and debossing will benefit from sturdier papers or premium stocks that can hold the raised or indented shape well. Hot foiling can be used on a wide range of substrates, as long as they can accept the tool temperature for short periods of time. Cold foiling works best with smooth, coated surfaces, which ensure the foil adhesive remains proud on the substrate surface.’

Mr Godson adds that creating a ‘perfect marriage’ between design, production process and raw materials is one of the biggest challenges. ‘Putting in technical expertise at the design stage can be critical in stopping these issues before they start,’ he continued. ‘How intricate is the design? Does the proposed substrate allow for a particular embellishment method? Are there available grades of raw materials to compliment the design specifics? We overcome these issues, and countless others by using top-quality dies, state-of-the-art machinery, and experienced planners/operators to ensure the best possible outcome for our clients.’

All4Labels’ Motherland showcases a wide variety of ‘premium finishings,

sustainable options and consumer interaction’

All4Labels also extols the importance of collaboration, saying that it works closely with paper suppliers and technological partners to explore the latest trends and innovations available in the market. An example of this has been Motherland, an All4Labels showcase dedicated to ‘premium and sustainable solutions that enable brand owners to explore new ways of enhancing their products’.

The specifications of Motherland suggest materials and technologies of the highest quality, she added: high-performance textured papers from Avery Dennison and Fedrigoni; micro- and nano-embossing with super fine high-precision details from H+M; silkscreens and 3D printing effects, super shiny metallic details from Kurz-Luxoro; and distinguished bottle designs from Estal.

‘Thanks to partnerships with top players in the industry, the showcase represented a synthesis of the wide variety of solutions that can be realised in terms of premium finishings, sustainable options and consumer interaction,’ said Ms Iannone.

Luxurious and distinctive

To focus on embossing and debossing first, these are sophisticated techniques that add depth, texture and tactile dimensions to printed labels and packaging. In the world of digital printing, embossing has become increasingly popular due to its ability to create luxurious and distinctive labels that stand out on store shelves.

These effects can be precisely applied to various materials, including paper, plastic, and metallised substrates, making it a versatile option for a wide range of products. The combination of digital printing and embossing offers brands the flexibility to create intricate designs with fine details, ensuring that every label not only communicates the product’s identity but also delivers a premium experience to the consumer.

As the demand for unique and personalised packaging grows, embossing continues to play a crucial role in elevating the aesthetics of digitally printed labels.

‘Embossing is all about creating a big impression – both functionally and aesthetically,’ states Paul Jones, sales and technical director at Coveris. ‘The deeper the emboss, the more visible it is to the eye as well as to the touch, creating a sensorial effect for consumers. Combined with a soft touch or tactile finish, this can create an incredible effect and is widely used within the beers, wines and spirits category to add value.’

Coveris’s Amberley Labels offers precision embossing for conventional print through a Rhino unit, and for digital with a new ABG Big Foot module.

The field of textured embossing – as hinted at in Paul Jones’s comments – is an interesting and growing one too, bringing yet more power to the embellishment and its impact. Paola Iannone of All4Labels observes that textured embossing enhances depth and detail, and ‘creates varied surface patterns, making products visually appealing and increasing interactivity’. She adds that, ‘This distinction is crucial for design aesthetics and user experience.’

Debossing – which pushes a design down into the face of the substrate to create a recessed effect – adds depth and texture, enhancing branding with a sleek, understated elegance that elevates the tactile experience. By subtly recessing text, logos, or patterns, debossing gives products an understated yet high-level look. Paola Iannone, All4Labels’ VP for marketing & communications, explains that the project is aimed at representing subtly recessing text, logos, or patterns, debossing gives products an understated yet high-level look.

Comparing embossing and debossing as a special effect, Jamie Godson of Baker Labels observes memorably that ‘embossing pops, while debossing is more understated’. Debossing ‘gives a more subtle, elegant finish’, he points out, often used to create a ‘minimalistic but sophisticated look’.

‘To get perfect results, we carefully control the pressure and temperature during embossing and debossing. Intricate designs can be tricky because if the die isn’t precise or the material is too soft, the details might not come out clearly. We take extra care at design stage to ensure all elements align to enable top quality results.’

Raised up Another way to achieve tactile effects is by using a digital printing system to create raised areas within a design. This is something that Durst highlights, saying it allows users to attain 3D effects without complex equipment and tooling.

‘Through precise ink drop placement and drop volume control, it’s possible to create beautiful, textured effects that can even be combined with foiling and/or special substrates,’ said Ivan Angerer, marketing specialist at Durst.

‘With proper artwork design playing with the High Opacity White with optional double white, it’s possible to develop patterns reproducing fine textures on paper and synthetic materials at a remarkable speed of 52m/min, adding vibrant colours derived from the extended gamut capabilities. Even with simpler hardware configurations, it’s possible to achieve good results at a not much lower speed of 40m/min.’

According to Mr Angerer, the potential benefits include low cost for high productivity, less waste, reduced labour costs, cost savings due to shorter production runs, light fastness, scratch and chemical resistance, application variety as it can be applied to a wide range of materials, and product certification and security labelling.

Making foiling a shining success

Traditionally, in foiling there has been hot and there has been cold. As its name suggests, hot foiling uses heat and pressure to apply foil, resulting in crisp, vibrant finishes. Cold foiling, on the other hand, applies foil using adhesive without heat, allowing for faster application and greater versatility in design.

‘Hot foiling is perfect for adding high quality finishes to luxury products, especially on wine stocks where the open fibres of the substrate make cold foiling very challenging,’ says Jamie Godson of Baker Labels.

‘With cold foiling, while faster and more flexible than hot foiling, the finish isn’t as deep and crisp as its heated counterpart. Cold foiling is a good option for large production runs when you need something eye catching and cost effective, but you would need to consider the artwork design and printing stock when deciding the best process to opt for.’

Profoil supplies a range of foils and dies to the sector, including for foiling onto paper, card, plastics, leather, wood and textiles. It says it is increasingly seeing foiling dies with more minimalistic designs being ordered.

Hot stamping foils consist of multiple layers, one of them being an adhesive on the back. This is activated by heat, says Profoil, but it works in conjunction with the amount of time (or dwell) and pressure that is applied on the die against the paper or substrate. Changing any one of these factors affects the result, in some cases changing the finished effect.

‘If one of these elements is off, the foil can scorch, bleed or be patchy. We always advise to vigorously test the heat, dwell, and pressure before proceeding with the final job – it is an art after all.’

Makeready can help with this, with products such as Presspahn, Pertinax boards, and Super Press Blankets all able to improve the final result by smoothing out uneven areas and allowing a cushion for a deeper, clearer impression.

Adding distinction with foil

Ross Hutchison, president of Universal Engraving, a UEI company, describes a recent foiling project:

‘Recently we had a direct opportunity to work with a brand manager wanting to add more distinction to their label. Discussing their vision, we created a Unifraxion die for them (foil stamping with a refractive pattern) to foil stamp a variety of options for their label. Essentially the die included a 12-up logo where we inserted a different Unifraxion pattern in each position. We proofed the die inhouse and provided the customer with the samples. This option gave our customer the ability to see different effects, with different foil shades and how the effects worked with the printed sheet.

‘During this process, it was important to assure that everyone knew how the final label would run. The brand manager needed to determine their printer and know what equipment would be utilised to produce the label. This helped to make sure that the effects and patterns chosen could easily be recreated in a production environment with the necessary tooling.

‘Once the brand manager chose the Unifraxion pattern and selected the foil shade, we then were able to work with their label converter to solidify that the substrate, foil, and tooling was working in unison to create a finished masterpiece.’

Digital foiling

Some significant industry names have been getting on board with foiling in recent times and bringing digital foiling solutions to the market. One of these is A B Graphic International, which has the previously mentioned ‘Big Foot’ hot foil stamping and embossing module with the Digicon Series 3, allowing multiple foil feeding across and along the web, where it delivers 50 tons of pressure for precise foiling results.

AB Graphic also supplies DigiJet – a digital embellishment module that can be deployed inline or offline, allowing for multiple processes in one pass, including spot varnishing, cold foiling and tactile screen effects on any size of print run, with no tooling.

According to AB Graphic, this last point simplifies and reduces set up times, helping users to turn around projects quickly and with minimal waste. DigiJet technology is available in single bar or dual bar configurations, can be adjusted on the fly and is suitable for varnish and cold foil of various thicknesses on the same label.

Eye-catching foiling produced by Harkwell

Another player in the foiling arena is Kurz, with products such as foils for hot foil stamping, cold foil transfer and digital transfer. On the digital side it has created a range of Digital Metal foiling systems, both sheetfed and webfed. One such system is the Kurz DM-Jetliner, which was installed at Amberley Labels, part of Coveris, in 2021.

David Richards, managing director of Amberley Labels, said at the time, ‘The Kurz DM-Jetliner means we now offer next-generation inline foiling capability and flexibility, with greater colour possibilities and brand control. Mass customisation of metallic finishes – variable metallised print and colour – creates a new level of versatility for design and print which is a real game changer for our customer base.’

‘Having this technology allows the creation and combination of labels that was previously unavailable; it also enables us to invest more future resources in additional embellishment techniques, such as silk screen and domed foil applications, embossing and hot foil to support continued innovation in this area.’

Amberley has used this system to create ecoLux, a print technology that makes ‘every label premium, sustainable and unique’.

Paul Jones of Coveris adds, ‘Ultra lightweight, coloured, variable foil is digitally printed to offer a luxury finish with a 90% metallic weight reduction and with no compromise to label recyclability. Providing an extended metallic colour gamut with rapid turnaround direct-to-print, no originations and no heat used in the application process, ecoLux is a pioneering example of luxury labelling without environmental compromise.’

Off the back of this capability, Amberley Labels has bolted on further digital finishing capabilities, including new digital silkscreen and embossing, and the ABG Big Foot for precise and rapid hot foiling, with reduced cost, set up and carbon impact.

Seeing the light

Kurz itself is steeped in traditional foiling as well as the nascent digital technologies. It says it is seeing increased interest in holographic and 3D effects, such as are possible with its Light Line and Silver Line hot foil stamping products.

‘Due to digitalisation and the visual flood, it has become more important to appeal to other senses such as haptics,’ explained Kurz UK’s Sara Hill. ‘Embossing and texture are therefore important. In cold transfer, individualisation through overprinting, but also the fine screening of the foil, is an important trend.’

Ms Hill adds that the main advantage of hot foil stamping with transfer products is the ‘additional effect’ – achieving metallised, high-gloss, matt, diffractive and coloured effects that cannot be achieved with normal printing processes.

Another digital metallisation technology to keep an eye on is Actega’s EcoLeaf which, as its name suggests, claims environmental benefits too, certainly in comparison with traditional foiling techniques. It is an ‘on-demand’ metallisation process, which only places metal flakes exactly where they are needed in the design, with no need for a PET carrier film or foil reels, hence the claim to reduce waste and plastic consumption and minimise environmental impact.

At Labelexpo Americas, Actega announced that Fujifilm and its 46k UV inkjet printbar is now an integrated part of the EcoLeaf system, allowing printing at up to 80m/min. Currently, EcoLeaf is being used by All4Labels, MCC, Reynders and EPL.

Harkwell’s embellished bottle labels

Poole-based Harkwell utilised a range of techniques to create a highly tactile ‘rock face’ embellishment for a whisky bottle label, adding foiling and debossing with an ABG Digicon finishing line and Tomlinson tooling, and a high-build effect via an inline screen unit. The label was printed on Harkwell’s HP Indigo. Andrew Mansfield, managing director of the business, commented, ‘It had to look like a rock face and feel like a rock face. It had a hole in the middle, a silver crest and a high-build name.’ ‘Thanks to Tomlinsons, we debossed rather than embossed, which was great advice. We used the ABG Big Foot for foil and deboss, added a textured varnish and flattened it to create that stone feel, and added the high-build name. The cutting of the hole was the easy bit!’

Trending digital and green

Of course, different embellishments can be used in tandem with each other, building even greater power into the overall impact of a piece. Care must be taken, though, to ensure that this approach works well, both on shelf and for the brand’s objectives.

The key trends, however, seem to the developing field of digital embellishment technologies and the onward march of sustainability – and clearly, the two factors are not entirely independent of each other.

‘With sustainability a constant focus of many brands, high-end labels need to not only be eye catching, but also eco-friendly. Digital embellishment aids production sustainability by reducing set up times, material wasted, and negating the requirement of manufactured solid tooling,’ observes Jamie Godson of Baker Labels.

Paul Jones at Coveris describes digital embellishments as ‘a shifting trend’, offering major sustainable and efficiency benefits over traditional flexo as brands shift towards a more agile reduced volume, increased SKU model.

‘With a lower carbon footprint, reduced or removed originations and direct-to-print agility, digital print is no longer just a short-run alternative to conventional,’ he concluded.

This feature article was first published in the October/November issue of Digital Labels & Packaging, which you can read online here; register here to receive future issues of the magazine