Global Graphics has launched version 2 of its ScreenPro screening engine for inkjet. This introduces PrintFlat technology developed to reduce non-uniformity in printhead performance across the web, commonly known as the ‘inkjet smile’ as well as other defects.

Product manager Tom Mooney explained that the company has also spent a lot of time in order to achieve considerable advances in speed to match the ever-faster inkjet presses. Version 2 is up to three times faster and can process variable data in real time at full press speed enabling printers to produce higher quality products.

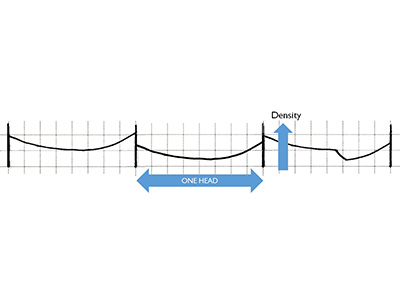

‘Our customers wanted a technology to address the banding that inkjet print bars commonly display,’ he said. ‘Printheads don’t have a uniform density distribution across the head resulting in visible banding. Different printheads will have different baseline densities and while these can be corrected by ‘tweaking’ voltages this is time consuming and can affect the life of the heads.

‘PrintFlat provides a calibration that corrects for these defects providing a flat, uniform density distribution across printbars. In addition to making improvements in quality ScreenPro 2.0 provides significant performance improvements and the ability for ‘Real Time’ screening driving data to the press at full speed.’

It is supplied to press vendors either as a cross-platform development component that can be integrated into any workflow solution, or with a branded user interface. Multiple engines can be run on the same server or offloaded onto separate computers. This parallel processing leads to blistering speeds, especially with dedicated ScreenPro engines sending print data at press speed directly to the drive electronics driving individual printbars for each colour.

CTO Martin Baily concluded, ‘High-speed inkjet is so new and we are all learning. Our software needs to be able to respond to the issues faced due to the fast development of this technology.’