With ebeam, ePac will be able to cut finishing times

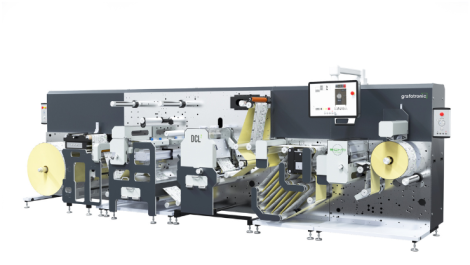

ePac Flexible Packaging will install an ebeam Core 100/760 EB curing unit, mounted on a GM EB30 coating line at its Wisconsin, USA, site in Q3, 2018.

With the purchase the company hopes to achieve instantaneous curing and a high-performance finish to overprint varnish (OPV) onto surface web printed materials from an HP Indigo 20000 Digital Press.

‘The addition of ebeam curing will enable us to create enhanced and high-performance finishes for our packaging,’ said Jack Knott, CEO. ‘We were the first flexible packaging business in North America to rely exclusively on the Indigo 20000. We’re excited by the possibilities offered by ebeam Technologies, and look forward to a mutually beneficial partnership over the coming years.’

With ebeam, ePac will be able to send fully-cured, OPV coated material directly onto the next stage of production, cutting finishing times to hours instead of days. This will greatly improve production throughput speeds and enable an overall faster time to market for ePac’s customers.

The new solution will also enable ePac to realise additional market opportunities by opening up a route to indirect food contact packaging. With ebeam-curable OPVs from GM there are no photoinitiators, thereby providing an FDA approved solution for personalised indirect food contact packaging applications.