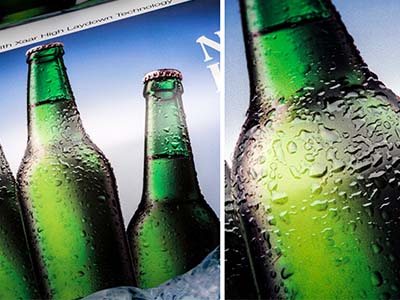

Tactile effects created with Xaar’s new High Laydown technology

A new High Laydown technology for printing textured effects on labels, folding cartons and products has been developed by Xaar. The company has also extended the 2001+ printhead product range to include UV applications, such as printing labels and cartons.

The latest technology, High Laydown (HL), adds to the company’s range of deposition technologies and enhances its growing intellectual property portfolio.

When incorporated into the Xaar 1003 and Xaar 2001+ printheads, HL can be used to print very high levels of UV clear varnish. The Xaar 1003 GS12U can print an 80-micron layer at 25m/min line speed, or a 50-micron layer at 50m/min, in a single pass, thereby building in texture as part of the print process.

As well as adding texture as part of the print process, the new technology can be used for producing raised foil effects. Tactile information effects such as warning triangles required on hazardous products and Braille can also be created without the need for an additional print stage or process.

‘HL technology adds a new capability to this very successful product range,’ commented Gerard Winn, senior product manager. ‘With minimal work, OEMs can upgrade their existing presses to incorporate the latest technology, and make textured labels and folding cartons much more accessible and affordable for print shops and therefore for their customers too.’

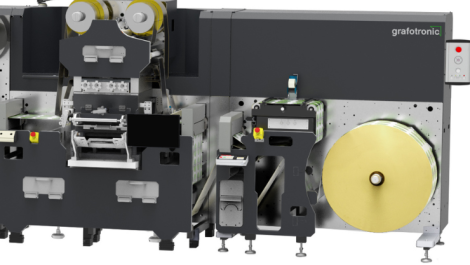

Separately the Xaar 2001+ family, announced in 2016 for ceramics applications, has been extended for UV print applications. With the 2001+ GS6U, it is possible to print 720 x 720dpi at up to 60m/min (6 pl binary), or 720 x 720dpi at 25m/min (four greyscale levels 6, 12, 18 pl).

The printhead incorporates multiple technologies unique to the manufacturer to ensure continuous and reliable printing in single-pass operation, maximising production output, minimising production interruptions and reducing the need for operator intervention.