Smurfit Kappa has worked with Sun Chemical to offer a new coding solution on its corrugated boxes.

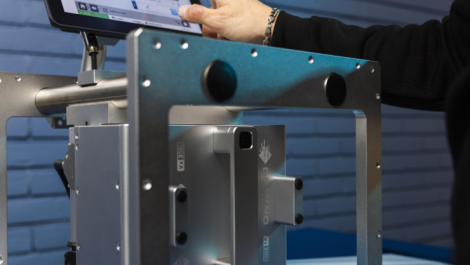

The coding technology for secondary cartons combines Smurfit Kappa’s flexo printed corrugated boxes with Sun Chemical’s SunLase activated coating system for late stage coding, allowing customers to laser mark packaging at the end of manufacturing operations. With the capacity to laser mark at the typical speed of an automated packing line, it offers a replacement for direct thermal labelling.

As a result, there are fewer disturbances on the packaging line as there is no requirement for labelling and printing. This saves the business time and ultimately, drives operational efficiencies. The SunLase system uses no inks or chemicals during production and is available in white and transparent laser-sensitive ink.

‘We are delighted to collaborate with Sun Chemical, experts in their field, on this laser-based marking solution, which is further evidence of Smurfit Kappa’s commitment to innovations that make a meaningful difference to the packaging needs of our customers,’ said Arco Berkenbosch, vice president innovation and development.

Michel Vanhems, SunInspire, special effects inks, functional coatings and SunLase product manager EMEA at Sun Chemical, commented, ‘As regulations for traceability continue to grow, combined with the need for delivering fast, efficient and cost effective output, our partnership with Smurfit Kappa has enabled us to combine our expertise to deliver a digital laser-based solution that meets all the demands of industrial applications. Having undertaken thorough testing of our application, and to already have it adopted by a world-leading organisation is testament to the benefits that it can bring in terms of versatile, high speed, late state identification for a wide range of secondary applications.’