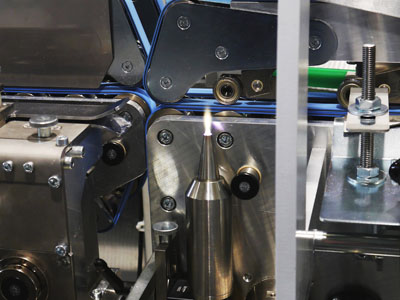

Plasma flame on Kama’s FlexFold 52i folder-gluer

Kama has added plasma treatment as an option to its folder-gluer, the FlexFold 52i.

First introduced at drupa 2016, the machine can now glue sealed, smooth surfaces, including as UV-coated, metallised or laminated cartonboard through the use of plasma. The first FlexFold 52i featuring the new option has been sold.

‘UV coatings in packaging is increasing, especially with digitally printed folding boxes and high-quality special editions,’ said CEO Marcus Tralau. The manufacturer developed the almost fully automatic FlexFold 52i especially for short run lengths. ‘We are now adding the plasma treatment as an elegant and efficient solution when gluing UV-coated folding cartons,’ he added.

The plasma treatment system consists of a plasma generator and a plasma nozzle with a transformer. When using the treatment, the coated surface is opened up by passing it over the nozzle, which gives off energised, ionised air to make the surface responsive. ‘The plasma is like an energy shower of air, it increases surface tension and activates molecules that the glue can hook onto,’ explained Mr Tralau.

However, the treatment only changes the surface temporarily. Surfaces without glue applied to them return to their original state. This makes the solution optimal for straight-line boxes (often used for pharmaceuticals), but also for crash-lock bottom boxes, such as for healthcare and beauty products, which have several bonding surfaces.