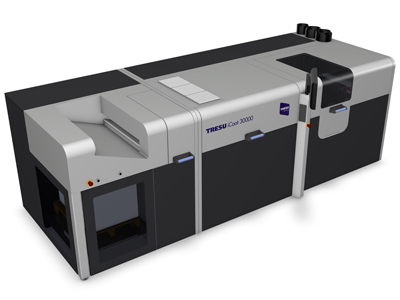

The Tresu iCoatcan apply water-based or UV-varnishes directly after the digital printing stage

Belgium based paperboard and label printer, Digilinck, has installed a HP Indigo 30000 digital press with integrated Tresu iCoat 30000 coater to meet growing demand for digitally printed folding carton packaging.

Two HP Indigo WS6600 roll-to-roll presses were previously the mainstay of the company, which supplies luxury packaging and self-adhesive labels to retail goods and pharmaceutical markets in Northern Europe.

‘The growth we experienced made it challenging to meet commitments, even when both machines were running three shifts a day,’ explained Vincent Oosterlinck, Digilinck’s owner and founder. ‘The HP Indigo 30000 together with the Tresu iCoat 30000 [a flexo coating unit that applies water-based or UV-varnishes], was the ideal complement to our WS6600 digital press machines. It delivers the identical quality cost-efficiently, yet with twice the productivity. This gives us the ability to grow and maintain the flexibility on which our competitive edge depends.’

Digilinck’s printing and coating line from HP Indigo and Tresu runs at 3450 B2-size sheets per hour, with a maximum of 4600 sheets per hour, enabling the company to print jobs in excess of 30,000 units in approximately two hours. The coater’s quick-change sleeve technology and fast chamber cleaning cycles make it possible to exchange jobs and varnish sets in minutes. Together the two machines provide a seamless single-pass printing and coating line for folding cartons, with minimal logistics or material waste.