Edale has become a reseller for FFEI’s Graphium hybrid digital inkjet label press in the UK and Ireland after a partnership was made between the two companies.

‘Edale becoming our distribution partner in the UK and Ireland for Graphium was a logical next step in what has been a very successful and productive relationship to date,’ commented Andy Cook, FFEI managing director. ‘Not only do Edale provide the essential transport element for Graphium but they also have a tremendous reputation, in labelling and packaging converting, for product innovation, quality and customer service – key values underpinning the whole Graphium concept.’

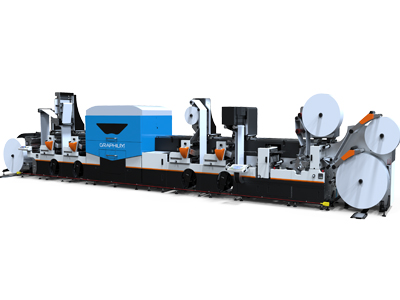

Whilst Edale and FFEI build each press jointly, Edale will be responsible for managing UK and Ireland sales, technical support and servicing. Edale builds to order the conventional press frame, based around its FL-3 press, including flexo and converting units. The Graphium digital unit is then added and the final press assembled and tested by Edale.

Graphium UV digital inks will also be sold via Edale. The press uses specialist inks developed by Fujifilm Speciality Ink Systems.

Mr Cook continued, ‘Working with Edale has been essential to the success of the Graphium hybrid concept. They bring to Graphium all the advances that have been made in flexo in the last couple of years. As a long-term player in the industry, Edale also share a number of qualities with FFEI. Perhaps most important of all we are UK manufacturers who heavily invest in finding innovative solutions to the challenges faced by label convertors.’

‘Developing the web transport, hybrid print and finishing technologies for Graphium over the last two years with FFEI has resulted in significant productivity advances. With our extensive product knowledge and established and loyal customer base, becoming UK and Ireland distribution is the natural progression for Edale,’ commented James Boughton, Edale managing director.

‘Edale has been involved in the design and development of web transport technology for single pass inkjet since 2002 and can observe the commercial potential that Graphium holds for the future of the packaging industry. The Graphium engine is robust, reliable and delivers exceptional print quality on a wide range of substrates and is exactly what is required to be part of a industrial print and finishing solution.’

The Graphium hybrid digital inkjet label press enables each graphic element to be produced by the most efficient process, be that digital or flexo. Shorter run jobs can be printed purely digitally, maximising the efficiency and time saving qualities of digital. For much longer run lengths efficiencies can be maintained by printing dominant colours, such as key brand colours or white, as flexo spot.

‘With runs of 3-4000 meters being viable, a label converter can cover the majority of its jobs with a single hybrid press, rather than investing in a stand alone digital inkjet press that will only cover the low run work,’ explained Mr Cook.