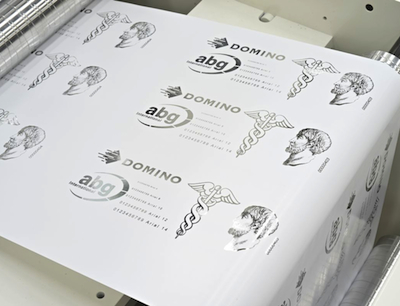

Domino has launched its first digital cold foil solution based around the Domino K600i digital print module, which prints a digital adhesive creating an image area prior to UV-curing and delamination.

Unlike some other inkjet systems that print metallic ink to provide a foil-like effect, the digital cold foil solution is based on real conventional metallic foil to provide a higher quality finish and enable the use of security and decorative holographic images within the foil.

Depending on the substrate, the digital cold foil solution can operate at speeds up to 75 m/min and can be supplied as a stand-alone unit or be retrofitted to an existing foiling station. It is offered in up to seven different foiling widths ranging from 108 mm up to 782 mm.

Philip Easton, director of Domino’s Digital Printing Solutions Division, commented, ‘We have been facing an increasing demand for a digital coil foil solution over the last seven years, so have now combined the latest higher resolution K600i print technology with an advanced adhesive formulation and a web handling solution supplied by AB Graphic International.’

Digital foiling presents an opportunity for security applications designed to prevent parallel trade and anti-counterfeit activity. The combination of holographic foil with digitally created images provides additional product complexity and makes counterfeiting increasingly difficult to achieve.

The label and packaging market, which is seeing a trend for shorter run lengths and multiple SKUs, is another segment that can profit from digital foiling. Easton explained, ‘According to our customers, production run lengths are getting increasingly shorter. More importantly, brand owners are expecting lead times in some cases as short as 24 hours. The only way a label converter can efficiently respond to this demand is by digitally printing the labels. And, if the produce then needs foiling, our digital solution can be cost effective but also an efficient way to quickly process multiple small runs.’