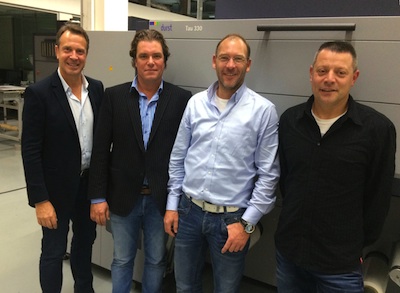

(L-R) Helmuth Munter, Durst segment manager, labels and package printing, with the Omnilabel team: Michiel Smudde, sales and marketing director, Mark Eshuis, director, and Marcel Klein Herenbrink, digital printer

Dutch company Omnilabel has invested in a Durst Tau 330 digital UV inkjet label press in order to open up new market potential with digital label production.

In 2010, Omnilabel was the first customer to install the Tau 150 label printer from Durst and since then, the company has successfully developed its digital label business, resulting in a 50% turnover increase. Due to the increasing demand of digitally printed label jobs, an expansion of the production capacity has now become necessary.

‘The new Tau 330 provides the means for us to further develop our core competence towards digital production,’ said Michiel Smudde, managing director. ‘In addition to the excellent print quality, the Tau 330 is equipped with a number of interesting features, such as the integrated chill roller for processing thin, heat-sensitive materials. Additionally, Durst provides low migration UV inks, which will help us to develop new business areas for our company in future.’

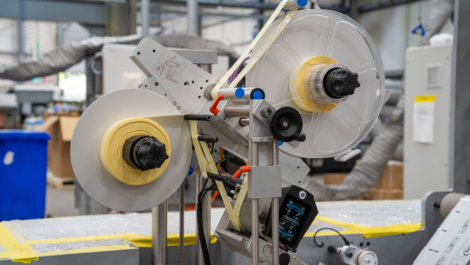

The Tau 330 is equipped with Xaar 1001 single pass printheads and has a maximum print width of 330 mm with a maximum print speed of 48 m/min. This allows a production capacity of 950 sqm. The standard ink configuration of CMYK can be upgraded on demand with white and two additional process colours such as orange and violet, which are indispensable for label applications with a pantone colour space. Even the standard version of the Tau 330 comes with comprehensive RIP software with integrated substrate- and colour management options.

With the new high definition print mode, the unit now achieves a resolution of 720 x 1260 dpi, which significantly improves the print quality and generates highly defined texts and intricate details in all graphics and images.

In order to ensure highest productivity with an entirely digital end-to-end workflow, the Tau 330 LFS version now features a new inline digital laser finishing system by the expert die-cutting company Spartanics. The integrated powerful 1000 Watt laser enables fully automatic job changeovers, while continuing production without interruptions.