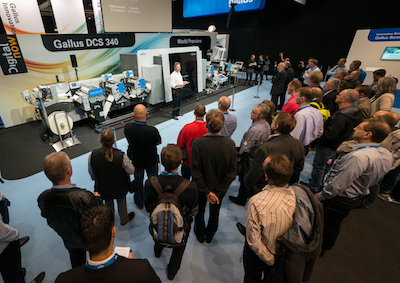

More than 700 visitors from across the world attended the Gallus Innovation Days 2014, which were held for the first time at the Gallus headquarters in St. Gallen, Switzerland.

The event ran from 23 - 25 September with the main focus on the world premiere of a new generation digital printing press for labels. Other innovations in 2014 included additions to the Gallus machinery and service portfolio, the printing accessories program, and the Gallus Screeny screen printing program.

The new Gallus DCS 340 digital inline label printing system DCS (digital converting system) was unveiled under the ‘no more compromise’ banner to a global audience. With a native resolution of 1200 dpi, print speed of 50 m/min and maximum register accuracy, the new digital press generation from Gallus sets high label-printing standards in terms of productivity, flexibility and quality.

The press is the result of a co-project involving Heidelberg and its partner in inkjet technology, Fujifilm, in response to the ever greater demand for short runs and customised or versioned labels. These trends have inspired a growing willingness to invest in digital print technology that enables Gallus to tap into new growth potential in this particular segment.

The demonstrations of a DCS 340 prototype enabled the visitors to see the printing quality and fast job changes that can be achieved without any paper waste whatsoever. ‘We are not going to stop at the current printing speed of 50 m/min,’ revealed Stefan Heiniger, COO Label Business, ‘but want to improve even further upon what is already a very decent rate by the time the Gallus DCS 340 goes to market a year from now. Our aim is to create the most attractive digital printing system on the market.’

As well as the new press, David Baumann, product manager at Gallus, demonstrated the practical benefits of the Gallus RCS 330 in combination with a QuadTech colour control system. This system automatically adapts the ink zones to the pre-defined target colours on the fly throughout the run, which prevents potential operating errors and unnecessary paper waste.

Another highlight was the direct matrix removal of a highly complex die line on the Gallus ECS 340 at top speed and entirely tear-free. This is made possible by the new, high-performance matrix removal device that can be retrofitted to the Gallus ECS 340 as part of the ‘Plus’ update package to further increase the existing machine’s productivity and economy.

Other new additions to the Gallus printing accessories program include the Polymount twinlock-coated printing cylinder that was demonstrated on the Gallus ECS 340 by Gallus Customer Service representatives, who also answered plenty of questions from the audience.

At the Gallus expert forum, top specialists revealed the latest trends and technical developments in narrow-web label printing. Mark Hanley, President of IT Strategies, explained the importance and impact of digital printing in the label business, while Jason Oliver, Digital Printing Manager at Heidelberger Druckmaschinen AG, predicted a fundamental change in the printing industry over the next few years as digital printing takes hold in print shop pressrooms.

Christof Naier, vice president sales & marketing at Gallus, remarked, ‘We are very happy with the way the event went, and the high number of visitors is evidence of the keen interest in our new digital inline label printing system as well as the need for it. The commitment that Gallus is investing in new digital printing technologies signifies another important step towards the full portfolio our customers require. This makes Gallus a truly all-round supplier offering tried-and-tested conventional products alongside brand new digital printing methods – all under one roof.’