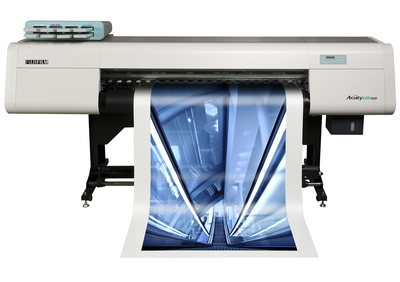

The Acuity LED 1600 large format hybrid inkjet printer

At Packaging Innovations 2014, NEC Birmingham, 26-27 February, Fujifilm will be partnering with FFEI to demonstrate the strength of the packaging solutions offered by both companies.

The stand will feature information on high quality solutions for the label and packaging markets, including the Graphium, Acuity LED 1600, and RealPro Toolkit.

At the show, label and packaging convertors who are keen to improve productivity and increase profitability, will be able to see how label artwork can be processed using RealPro Toolkit, in preparation for printing on Graphium, and how a complementary package prototype for the same product can be printed on the Acuity LED.

The Acuity LED 1600 is a large format hybrid inkjet printer which produces packaging prototypes, including solutions distinguished by special varnishing effects or spot colours. It achieves a combination of up to 20 msq/hr productivity and excellent image quality, supporting substrates up to 1,610 mm in width and designed to print on rigid sheet substrates up to 13 mm thick.

Another key feature of the machine is the inclusion of six ink colours, with the addition of white and clear ink as standard. The machine can apply these in a single pass to produce premium matt and high gloss finishes with a much higher efficiency than a conventional printer, where colours in conjunction with white and clear inks are applied in separate passes.

‘Thanks to its special varnishing effects and flexibility as a printer, the Acuity LED 1600 can quickly create high-quality packaging samples that stand out on the shelf,’ explained Steve Cookman, product manager, wide-format inkjet, Fujifilm. ‘Fujifilm has long been a key player in print, and we are now extending our solutions to the packaging market, which is one of the reasons why we’ve decided to exhibit at Packaging Innovations for the first time.’

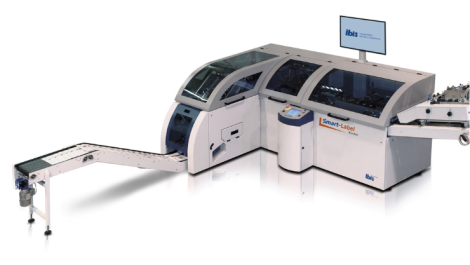

The Graphium digital UV inkjet press, manufactured by FFEI and distributed by Fujifilm in the UK, has been developed for printers specialising in the labelling and packaging sectors who want to increase margins and revenue streams on their short to medium print runs.

Andy Cook, managing director at FFEI, said, ‘Graphium represents a new kind of inkjet press that, when combined with the Fujifilm Uvijet Graphium ink developed specifically for label and packaging applications, breaks new ground in terms of the performance that can be achieved from a digital printer of its calibre. For converters, that means consistent proof-to-press match and alignment to colour standards, yielding high-quality, vibrant printing and excellent adhesion, light fastness and durability.’

FFEI will also be showcasing RealPro Toolkit, its software suite of tools designed to overcome the challenges of a labelling and packaging pre-press cycle, and which was launched at Packaging Innovations 2013. RealPro Toolkit provides advanced productivity tools for document specific label and packaging pre-press tasks directly within Adobe Illustrator.

Consisting of over 12 modules, the software addresses specific pre-press workflow requirements such as file editing and preparation, colour management, trapping and step and repeat tasks. Features also extend to specialist tasks such as cylinder repeats, patterns and artwork pre-distortion, all displayed in a user friendly interface.