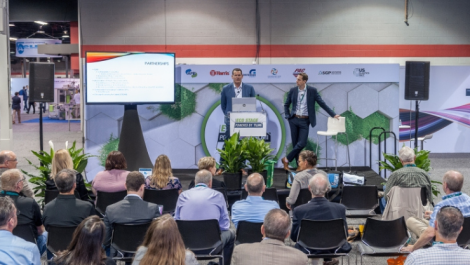

(L-R) Elliot Longly and Simon Allen, international design at Lush, with Peter Swann of Intec Printing Solutions

Lush, the leading global manufacturer of fresh handmade cosmetics, has invested in an Edge 850 Pro Label solution from Intec Printing Solutions.

Having extensively researched the market in a bid to improve the quality of its bespoke labels, which were historically produced on a laser printer, the company opted to invest in the Edge 850 for a number of reasons. The most significant of these being that the test sampling of its own labels, carried out by Intec, showed a big improvement in quality when produced on the system.

This jump in quality proved to have a positive effect on the company image and has also improved in-house presentation when developing new cosmetic ranges.

Located in the manufacturing digital unit where Lush showcases its new cosmetic products to customers both in person and online, the Edge 850 is intended to support the short run labelling requirements of the company’s exclusive product ranges by enabling the high quality production of a multitude of versatile label solutions.

Another bonus to Lush was the printer’s ability to print onto a wide range of substrates, including its shower proof range of labels by utilising digital PE laser material.

Based a stone’s throw from Intec’s UK international headquarters in Poole, Lush was keen to work with a local company. By investing in this system, it could support the local economy and also benefit from Intec’s comprehensive support and backup during the installation phase.

Peter Swann, UK & international sales manager, said, ‘We are delighted to win the business from this worldwide global leader in fresh handmade cosmetics.’