The free take-back services for HP Indigo supplies that HP offers its customers is now expanded to include series four binary ink developer (BID) base and BID roller used in the HP Indigo 10000 Digital Press

Demonstrating its commitment to environmental responsibility in the printing industry, HP has made a number of developments that will help to reduce the environmental impact of Indigo digital prints.

The new developments include trials that demonstrate the deinkability of Indigo prints in typical graphic arts paper deinking mill configuration, fully recyclable packaging for ink cartridges, the expansion of its take-back programme for recycling consumables, and the reduction of the HP Indigo’s carbon footprint.

Indigo prints are fully recyclable and can be placed in normal recycling collection. Deinking, or removing ink from paper fibres, is one of the key steps in the paper recycling process for manufacturing recycled graphic arts papers.

Over the last few years, the company collaborated with a range of industry and academic deinking experts to gather lab-scale, pilot-scale and mill-scale deinking data that verify its prints can be deinked in a typical graphic art paper deinking mill configuration.

In June 2013, Voith Paper, a leading supplier of deinking equipment, and the Paper Technology Department of PMV Darmstadt, a leading German technical institute, conducted two pilot trials with 5% and 10% Indigo feed. The research found that even with 10% Indigo feed, the pulp produced in the trials was suitable for standard and higher quality graphic arts recycled paper grades.

‘These pilot plant trials have convincingly demonstrated the deinking ability of HP Indigo prints using standard 2 loop deinking processes,’ said Jürgen Dockal, product development engineer, Voith Paper. ‘Proven equipment and standard deinking chemistry can be used, and parameters such as brightness development, ash content and yield are unaffected by the presence of up to 10% Liquid ElectroPhotographic prints.’

PMV-Darmstadt has made significant progress in developing a lab scale 2 loop test that correlates with the Voith Paper pilot trial.

These results complement two previous full-scale mill deinking trials, which were conducted in collaboration with Arjowiggins Graphic at its 3 loop Greenfield deinking mill in Chateau-Thierry, France in November 2011 and October 2012. In the mill-scale trials, 5% Indigo Liquid ElectroPhotographic prints (LEP) were added to the standard mill furnish. In both cases, high quality deinked pulp was produced without affecting mill process efficiencies or operating parameters.

‘The results of the pilot-scale trials show that printed paper from HP Indigo digital presses is compatible with typical graphic arts deinking mills even at levels higher than what likely would be encountered,’ said Yogev Barak, director of current business management, Indigo division. ‘Along with results from the Arjowiggins deinking mill trials, these latest results show that HP Indigo users can continue to feel confident that HP Indigo prints can be recycled back to high quality graphic arts papers.’

As a part of the company’s on going commitment to environmental sustainability, it has introduced improved ink cartridge packaging for the Indigo 6000 and 7000 series Digital Presses. The new cushioning tray is made of 100% recycled, moulded pulp and is 100% recyclable. Users can now dispose the cushioning tray with the ink cartridge’s cardboard box.

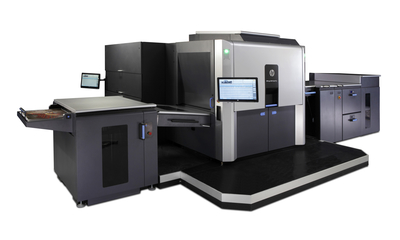

The company’s free take-back programme is now expanded to include series four binary ink developer (BID) base and BID roller used in the HP Indigo 10000, 20000 and 30000 Digital Presses.

The company will also continue its programme to offset carbon emissions associated with the manufacturing and integration of the new generation Indigo Digital Presses. Working with the Good Energy Initiative, it supports projects in the community that offset the net contribution of carbon emissions from the manufacturing process. As a result, all HP Indigo series three presses are manufactured carbon neutral.