Colordyne Technologies showed its CDT 1600-PC Laser Pro the latest digital label printing solution powered by Memjet technology, at Labelexpo, offering true print quality.

The CDT 1600-PC Series complements traditional printing services providing flexibility in handling print jobs that may be inefficient and cost prohibitive on existing CMYK flexo presses.

‘Brand owners should not have to settle for finished labels that look and feel differently from traditionally established and accepted print methods, just because they are digitally produced,’ said president Sean Marske. ‘At Colordyne, our mission has always been to engineer digital printing solutions for the converter that effectively augment their CMYK flexographic printing services, and the CDT 1600-PC Series achieves this goal.’

By incorporating CDT digital solutions, converters can queue mixed-copy and mixed-colour print runs in succession as efficient, stand-alone jobs. Furthermore, shorter print runs can be broken out of large, multi-job blanket orders and produced on the CDT 1600-PC to complement traditional flexo printing and boost profits.

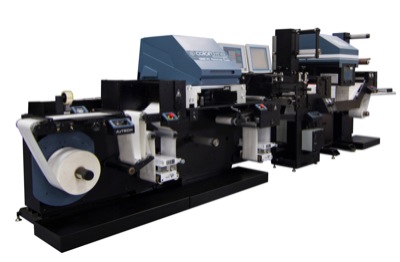

The CDT 1600-PC Laser Pro is a full colour digital printing system with high resolution printing and speed which features a high speed Laser Die Cutting System to make the industry’s fastest and most affordable integrated printing and converting system on the market.

AzTECH Converting Systems manufactured the web handling system which includes 10″ maximum web width and precision servo web control with an operator touch screen.

The CDT 1600-PC Printing System integrates LasX Industries’ V400 Laser System to kiss-cut, slit, or perforate label materials. Colordyne’s 1600-PC Laser Pro may be equipped with a complete flexographic print/coating station with UV curing, a lamination tower for applying over laminate, a pneumatic waste windup, and an adjustable underscore unit to provide a complete in-line printing system with short set-up and run times.

The 1600-PC Laser Pro offers the ultimate in digital efficiency and cost effectiveness. Dramatically increase short run profitability by reducing the job start up waste and change over time between jobs. All while maintaining 1600 x 1200 dpi resolution and print speeds of up to 49 m/min.

With the addition of AzTECH’s state of the art laser die cutting finishing systems, operators can move from one print job to the next, regardless of image, colour, shape, or size, eliminating the need for an extensive rotary die inventory.