The Tau 330 high speed UV inkjet label press

Durst will launch a new range innovative solutions for the label industry at Labelexpo Europe 2013. For a complete digital end-to-end workflow, the Tau 330 high speed UV inkjet label press will be showcased with inline digital laser finishing that incorporates laser die-cutting technology from Spartanics, with 1000 Watt laser for highest productivity and automatic job changeover to handle multiple jobs in a single run. For a complete finishing process, optional UV coating and lamination can be added.

The company will also introduce the new Tau low migration UV Inks from Sunjet. The ink components all appear on the EuPia and Swiss Ordnance positive lists and do not utilise material specifically excluded on the Nestlé list, which when combined with the specially designed UV curing system can achieve migration limits of <10ppb.

The Durst Tau 330 together with this ink will expand the range of suitable applications for unsupported foils, such as blister packs, yogurt lids and many more. Depending on application requirements, Tau 330 users may now choose from two different UV inkjet inks: the standard UV inks for all industrial applications, or the very new LM inks.

To cover a broader range of applications, the press is now also suitable for applications using non-PS materials. On stand at the show will be a second Tau 330 press with built-in chill roller that allows the printing of unsupported films and foils. The press will be fitted with a high resolution video inspection system from Nikka for increased print quality, reliability and production security.

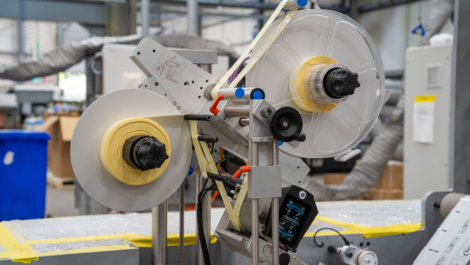

To increase its modularity even further, the press can be installed with external unwinder and rewinder units as well as other finishing devices, thus allowing a full integration of the press into nearly any existing production workflow. The specially designed connection box provides thereby all related signals to synchronise with external devices.

With over 15 installations during the first half of 2013, the Tau 330 sets new dimensions in digital UV inkjet label printing. The system features a maximum print width of 330 mm and a printing speed of max 48 m/min reaching an hourly production capacity of 950 square metres.

Its standard colour configuration CMYK can be completed with optional white, and two optional process colours, orange and violet, essential for label applications that require accurate Pantone colour matching. Furthermore, the standard configuration also includes RIP software with built-in substrate and colour management.