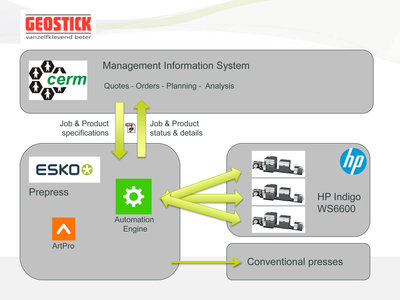

This flowchart shows the workings of the new system

Geostick has implemented a highly automated and integrated workflow for its prepress and administration from Esko and CERM to to make the most of its label presses.

‘With the automation now in place, we can do more work in less time, and we continue to improve our performance every day,’ said, Cees Schouten, technical director.

‘Switching to a new MIS-system is not an easy process, as it is the heart of your entire operation,’ added Mr Schouten.

While implementing the MIS solution in its sales and order department, the company’s prepress department started using Automation Engine at the same time.

Mr Schouten explained ‘To start, we had to enter all available information on clients, orders and products into our systems. This took extra time and work, but as soon as the first repeat orders came in, we immediately benefited from those efforts. Our new configuration meant that these repeat jobs went directly to press – without human prepress-intervention.’

Implementing the integration to Automation Engine included having a solution architect on site for five days, who analyses the existing situation, configures the new automated workflow and trains staff.

Earlier this year, the company replaced its existing three HP Indigo WS6000 digital presses with three new HP Indigo WS6600 presses.