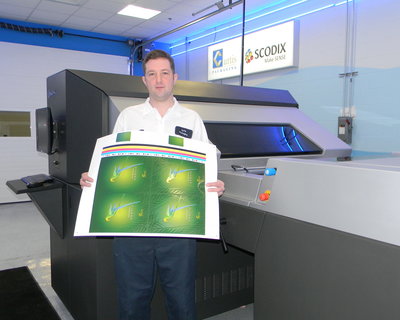

Martin Perry, Scodix pressman with the new press

Scodix has installed and implemented one of its S series presses at Curtis Packaging, in Sandy Hook, Connecticut, in the US. A provider of luxury packaging solutions and manufacturer of high quality folding cartons for global brands, Curtis purchased the Scodix press after executives saw it in operation at Graph Expo 2012 and had system shipped directly from the show floor.

Now after a few months of operating the press, the company is recognising significant benefits with the machine allowing it to create eye-catching projects with new memorable effects and provide a new marketing tool that is opening new doors.

With a turnover of $40 million, the folding carton company has been in business since 1845 and produces high-end packaging for customers including Estée Lauder, Elizabeth Arden and Jack Daniel’s.

‘People come back to us for our creativity and our ability to execute extremely difficult packaging,’ said CEO, John Giusto. ‘We do the kind of work that many other people are afraid to do or aren’t capable of doing. Scodix fits right in with what Curtis is all about – it’s a press that is unique and allows us to be creative. There’s no limit to what you can do with it: the only limit is your imagination.’

One of the first pieces produced was a unique holiday card for customers that highlighted the Scodix advantages including granite and sparkling effects and raised elements.

‘The holiday card was beautiful,’ enthused Mr Giusto. ‘The contrast between glossy, matte and raised effects provides the best look. We used a foil laminated board as the base and put down two hits of white ink with two hits of matte varnish on top of it. Then we reversed out of those two ornaments. For the red ornament, we raised up to the maximum height the machine is capable of and added a high gloss, so it’s very rich. And then for the other teal blue ornament we added a sparkling effect. It was very cool and unique.’

The Scodix S series press, with RSP (rotate, scale, position) technology, based on two CCD cameras and highly sophisticated mathematical algorithms, features 99 gloss units, up to 250 microns in polymer height, variable density capabilities from 1 to 100%, and unlimited colours with the Rainbow station and the digital glittering process. The press handles sheets to 20 x 29 inches (B2+ size sheet format).

The company frequently wins awards thanks to its innovation. At the 34th Annual Package of the Year Awards 2012, it received the silver and bronze awards in the fragrance category for the packaging of Coty’s Nautica Aqua Rush and Halle Berry Closer. In 2011 in a worldwide competition, Curtis was awarded ‘Best Applied Decorative Product’ by the IHMA for the Beyoncé Pulse Holographic carton.

To produce award winning packaging, the company takes many measures including developing proprietary printing processes, such as CurtCoat, a coating that offers an additional dimension of high gloss luster, and CurtChrome, a recyclable metallic printing process. ‘Innovation is paramount to delivering superior packaging solutions’ is a philosophy that has driven Curtis Packaging in every aspect of business.

‘You have to find a way to differentiate yourself to get the opportunities to do the type of packaging we do,’ added Mr Giusto. ‘When a designer comes up with a new package or something unique, we come to mind.’