Mercian Labels Group officially launched its digital printed cartons service to the market at the Packaging Innovations show in March. It uses the new Xeikon 3000 press with ‘a unique new inline conversion process’. This is the clever part and the company is being coy as it believes this proven system provides a significant advantage. Mercian is now delivering variable data and multiple designs onto printed folding cartons, cost effectively in short runs. Managing director Adrian Steele commented, ‘The conventional sheetfed litho manufacturing process for printed folding cartons limits the creativity that brands wish to incorporate into their packaging. Digital printing permits the inclusion of personalised content on every pack, with infinite versions for trials as well as inclusion of unique brand protection features. The Xeikon imaging technology we use offers fantastic full colour 1200 dpi quality using light fast and FDA approved food safe toners.’

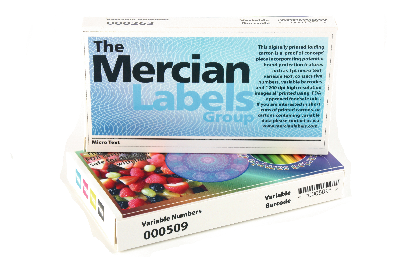

Mercian has decided to use a proven stock, a high quality 400 micron folding cartonboard, and can incorporate several added value features including security features such as micro-text, variable barcodes and variable text and numbering.

Applications include prototyping, market tests, short run batches, security packaging and unique direct marketing content. The company has combined its digital print expertise with an innovative converting process to print and die cut the cartons in a single pass, ready for folding and gluing. It claims the die origination is cheap and quick, and it will bring lead times down to those offered to labelling customers, typically three to five days from artwork approval.

Dr Steele continued, ‘Our labelling experience shows us that customers who have taken advantage of the benefits of digital printing have seen significant increases in their businesses as multiple SKUs appealing to smaller but higher value niche markets becomes cost effective. We expect a similar trend to happen in printed folding cartons.’