The new laser coders add unique numbers and dates to gin and whisky bottles

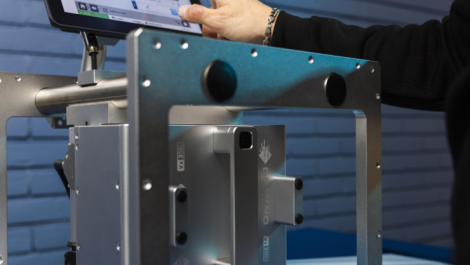

Two CSL30 laser coders from Linx Printing Technologies have been installed at Bruichladdich Distillery, where they are delivering high-quality codes and significantly reduced downtime.

Based on the Isle of Islay in the Inner Hebrides, the company installed its first Linx CSL30 coder on its gin production line last year. Having been impressed with the results, it has now installed the same machine on its malt whisky line.

‘We installed our first Linx CSL30 during a period which saw a 47% growth in our Botanist sales in the previous year,’ explained Jonathan Carmichael, bottling hall manager. ‘In order to adapt and keep up with this unprecedented demand, we took the opportunity to re-configure our line in another warehouse, adding some new machinery.’

Installed in the bottle labeller, the CSL30 codes two lines, 5mm in height, onto the bottom of the glass gin bottles. The codes comprise a line number and a batch code, including a unique bottle number and the bottle’s production date and time. The line currently runs at 2100 bottles per hour, 9 hours per day, producing 1.2 million bottles per year.

This capability of laser coding to produce a visible code on every colour and shade of bottle is particularly important to Bruichladdich, many of whose whisky bottles are black.

Mr Carmichael concluded, ‘As a producer of premium spirits, it’s vitally important that the codes on our bottles are clear and sharp and in keeping with the brand’s expectations.’

Originally founded in 1881, and reopened as a progressive distiller in 2001, Bruichladdich produces and sells high provenance whisky, distilled using much of the original Victorian machinery. In recent years it has expanded into gin under the brand name The Botanist.