Focus Label Machinery has held a successful open house where it showed its digital and flexo printing capabilities. The company’s d-Flex Hi-Q hybrid inkjet press was one of the highlights of the event.

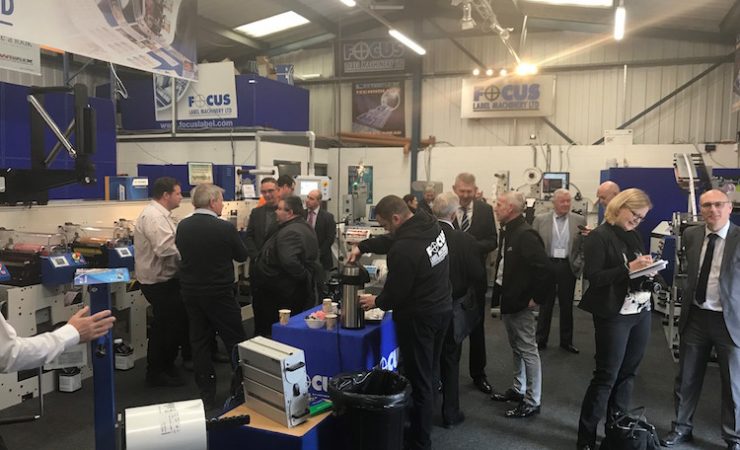

Focus invited visitors to its demo facility in Bingham near Nottingham, on 26 and 27 March, along with partners Industrial Inkjet (IIJ), Phoseon Technology, Lundberg Tech, RotoMetrics, Flint Group, Flexo Concepts, Cheshire Anilox Technology, Meech International, Hybrid Software, Nazdar Inks, Business Asset Warranties and Herma UK.

The company’s d-Flex Hi-Q UV inkjet press was the star of the open house. The hybrid set up combines the flexo expertise of Focus with an inkjet module from IIJ to deliver single-pass production of short run labels on demand. The press is available in 250 and 330mm widths and runs at speeds up to 50m/min. The four-or five-colour (CMYK+W) UV inkjet module on show was IIJ’s ColourPrint 223 HiQ model, which features Konica Minolta 1800i printheads to deliver 600 x 1200dpi. The front end software and RIP for the d-Flex comes from IIJ’s partner Global Inkjet Systems, while automated colour management software from Colourgate can be added as an option.

The converting part of the hybrid system is fully modular, which means each can be designed to the exact needs of the customer, both in terms of printing and converting capabilities and in terms of investment level.

Two flexo machines were also on display in the demo centre. A Proflex 330 SE servo-driven press was producing high-quality, four-page peel and reveal labels. A six colour e-Flex 330 servo machine was printing a food label with a high opaque white on transparent BOPP film, using the Phoseon FireJet FJ601 UV LED curing system and plates supplied by Brownett. Anilox rollers were supplied by Cheshire Anilox Technology and doctor blades by Flexo Concepts.

Visitors also saw the WasteTech 80 matrix handling system from Lundberg Tech in action, fitted on a Focus FS330 blank label slitter rewinder. This ‘all-in-one’ system captures, cuts and collects waste matrix and edge-trim waste, and garnered a lot of interest.

Antony Cotton, sales manager, expressed his satisfaction with the event, saying, ‘We would like to thank all our partners, suppliers and visitors who attended over the two days and helped make the event another great success. We were very pleased with the turnout and look forward to building on this and making the event a regular feature in the calendar. We believe that having multiple live demonstration models, along with the support of our partners and their respective technology, make this a unique event with a great opportunity to informally network whilst seeing live equipment demonstrations.’