Global Graphics Software has launched version 12.1 of the Harlequin RIP, which introduces additional features for labels and packaging workflows, including support for the new ISO standard for processing technical marks, and expanded support for systems requiring multiple RIPs to handle high data throughput requirements.

PDF Processing Steps (ISO 19593‐1) is a new industry standard designed for labels and packaging workflows that specifies a standard way of encoding processing steps, such as die and fold lines or dimensions, into a PDF file. It provides an unambiguous way of marking the technical content that is required in the finishing step of the production workflow but not intended to be printed.

‘You can say to Harlequin 12.1 ‘just give me the design content in the PDF with no processing steps’,’ said CTO Martin Bailey, ‘or ‘just give me structural processing steps and nothing else’, without needing to know what name the designer assigned to each item. Prior to the formulation of this ISO standard designers could use ad hoc naming conventions and methods to describe a processing step which increased the risk of error and of wasting material.’

The new version also extends support for systems using multiple RIPs by introducing an expanded framework, called Harlequin Scalable RIP, which is designed to support press vendors in building increasingly higher speed DFEs to drive increasingly faster presses. It gives press vendors access to a complete scale of solutions from a single RIP, through multiple RIPs on a single server, up to multiple RIPs across multiple servers. Mr Bailey said that Global Graphics is seeing the demand for speed continuing and that most vendors have or are looking to step up from 600 x 600dpi to 1200 x 1200dpi print resolution and expanding the colour gamut, which in turn puts much higher demands on the RIP’s processing power.

‘The highest data rate for an inkjet press is now an astounding 45GB per second and we already drive those presses through Harlequin,’ said Mr Bailey. ‘With the Harlequin Scalable RIP press vendors can bring high‐quality, highly robust solutions to market even faster, and without significantly expanding their own development teams for their initial integration.’ He added, ‘Speed is a priority for Harlequin because a faster RIP requires elss hardware, reducing the cost of materials and the footprint as well as the energy use.’

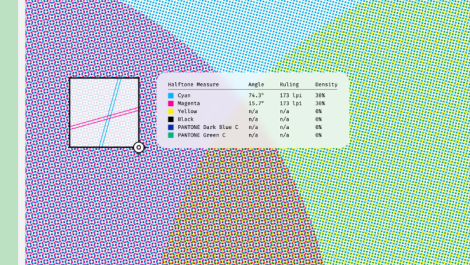

Harlequin 12.1 also introduces seamless screening for repeats that are not simple rectangles, for example, for staggered imposition of hexagonal or rhomboid-shaped labels. It is most commonly used for flexographic print sleeves or for non-publication gravure to avoid causing artifacts, or ‘zip lines’, when the same screened raster is printed multiple times along the substrate without gaps in the graphics.

Finally, the release introduces support for Windows BMP files in response to requests from mainly the wide format sector.