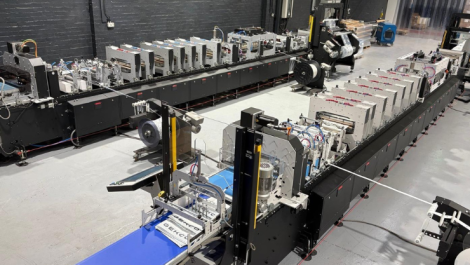

Baker Labels has installed an HP Indigo 20000 digital press, as the trade printer solidifies its involvement in the market for digitally printed flexible packaging.

The toner print engine has already been installed. Alongside the digital press, Bakers has opted to invest in laminating and pouch making to offer a full flexible packaging service.

Having previously done some work printing sachets and shrink sleeves, managing director Steve Baker sees this as a natural evolution for the company. ‘The time is right. The technology is there, as is the demand and volumes to succeed in short-run flexible packaging.’

Of the supporting investment in converting, Mr Baker continued, ‘We want to have full control of the process, which is why we’re adding laminating and pouch making. Key is the ability to offer a fast turnaround. If you’re outsourcing converting, it’s going to add weeks on. Eventually we want to be able to offer a turnaround of less than two weeks.’

The laminating and pouch making hardware is to be installed later this year. Bakers anticipates being fully operational with its digitally printed flexible packaging offer early next year.

Read more about this investment here