Benelux-based MIS specialist Cerm and German workflow software expert OneVision Software have entered into a technical partnership.

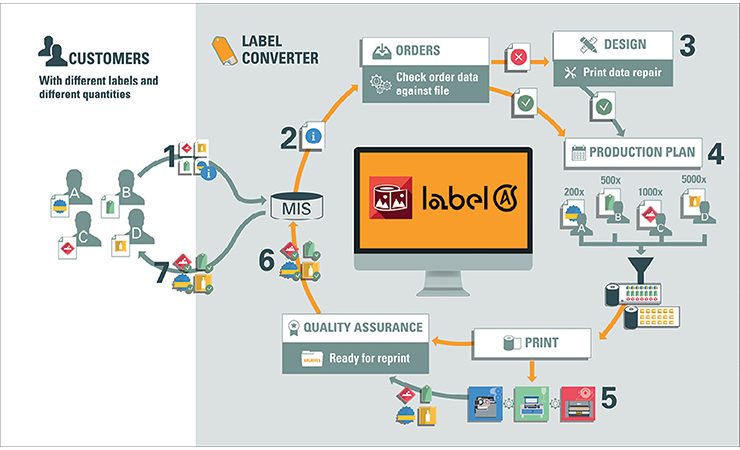

The primary focus of the two companies is to integrate their software and enable an automated end-to-end workflow for ‘smooth, highly efficient label production’.

The collaboration provides traditional and digital narrow web label printers with consistent automation of their label production. Due to the full compatibility and the direct connectivity of the two systems, order management and print data processing operate flawlessly, it is claimed.

The integration of the two systems enables label printers to benefit from the core competence of both companies. Cerm software is an MIS system for structuring business processes and organising administrative workflows of label and commercial printers. With its Label Automation Suite, OneVision Software offers a trouble-free print production process. The automation suite acts as middleware between the MIS and the RIP/DFE. Once the order for a label job has been received in Cerm’s MIS, OneVision’s Label Automation Suite automatically prepares print data and finishing. Either of the two software systems actuates the printing press.

In addition, special functions such as nesting, a cut line manager and a barcode generator, as well as the creation of white and varnish masks, enable automated preparation for finishing and embellishment.

An integrated production planning system enables collective printing of cross-customer jobs and significantly increases the throughput of label printers. The print-ready file then gets printed and, in the next step, sent and invoiced through the Cerm system.